A kind of inorganic superhydrophobic material and its preparation method and application

A super-hydrophobic and inorganic technology, applied in metal material coating process, vacuum evaporation plating, coating, etc., can solve the problems of poor temperature and corrosion resistance, achieve good temperature and corrosion resistance, and meet application requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Embodiment 1: Preparation of inorganic superhydrophobic material

[0051] (1) Cleaning the sample: Sonicate a soda lime glass sheet with a size of 50×30×0.5 mm in deionized water and acetone for 30 min in sequence.

[0052] (2) Vacuuming: the sample is placed in a vacuum chamber, and the vacuum chamber of the magnetron sputtering equipment is evacuated to a vacuum degree of 3×10 through the pumping system. -3 Pa.

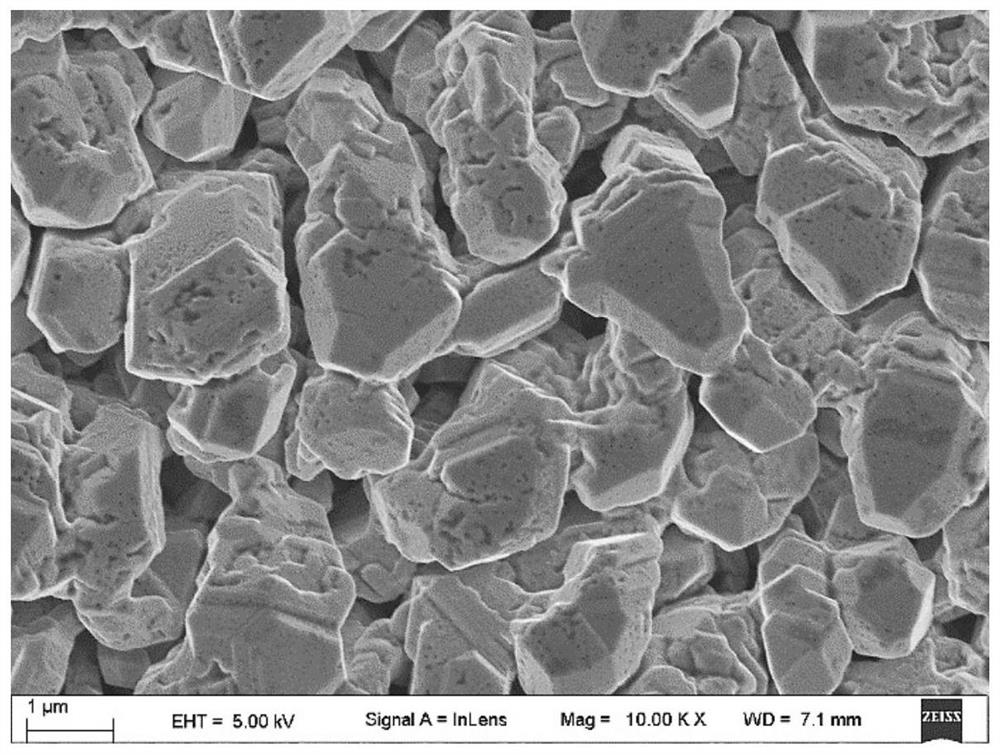

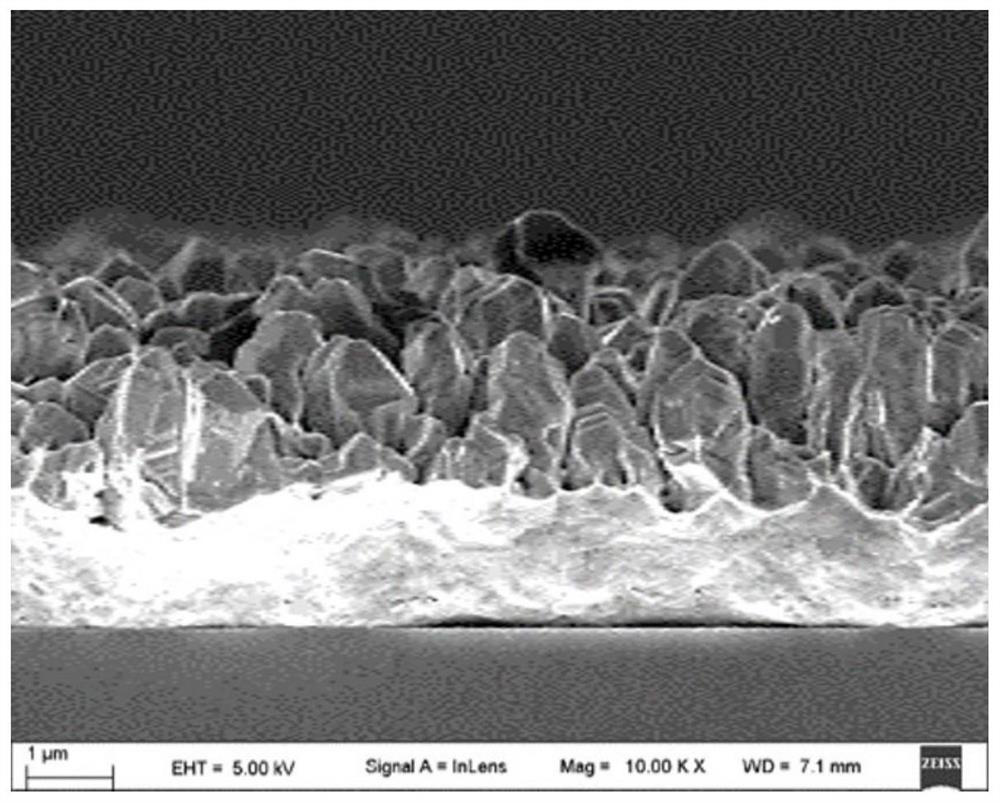

[0053] (3) Preparation of Cu film with micro / nano structure: feed Ar gas into the vacuum chamber, keep the Ar flow rate at 30sccm, keep the working pressure in the vacuum chamber at 0.8Pa, adopt magnetron sputtering to discharge the Cu target, the purity of the Cu target 99.8%, the size is 145×100×6mm, and the power density of the control power supply is 120W / cm 2 , the deposition rate is controlled at 1 μm / min.

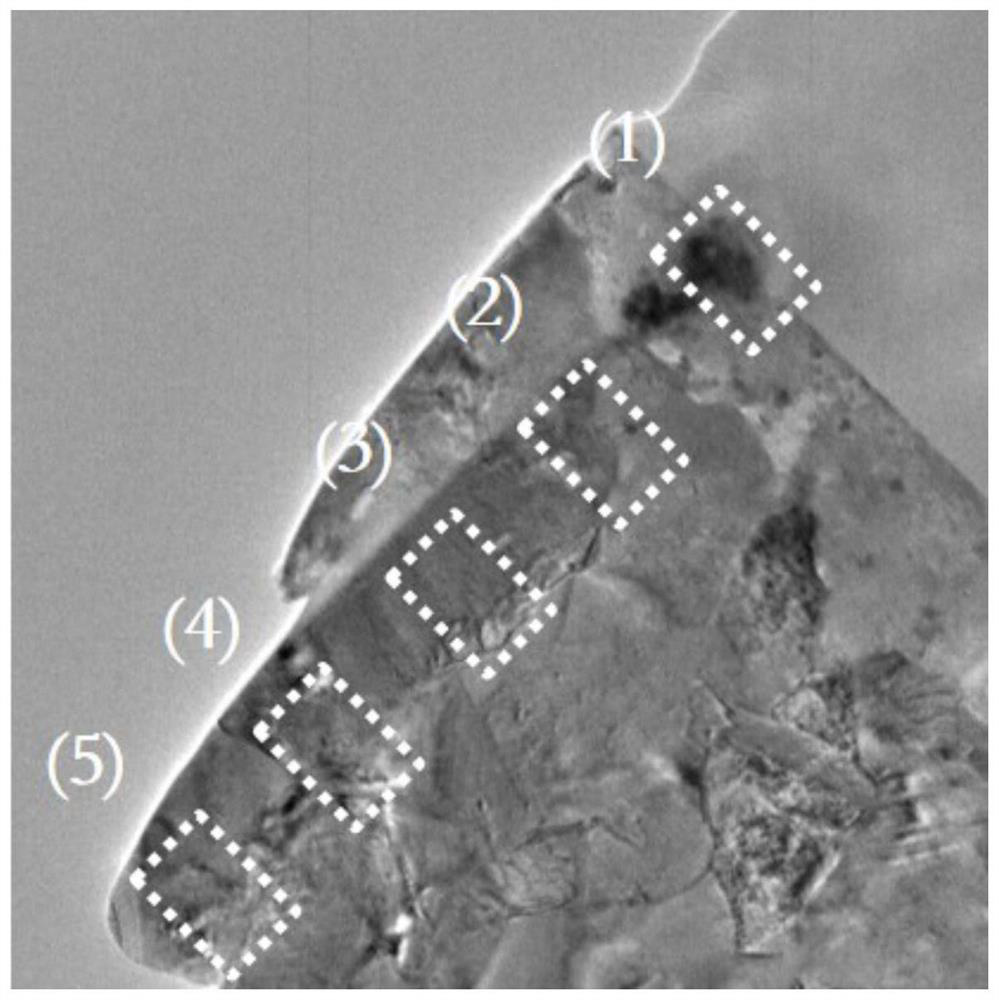

[0054] (4) Cu / Cu 2 O / CuO micro-nanostructure surface preparation: the micro-nanostructure Cu film prepared by magnetron sputtering was oxidized...

Embodiment 2

[0056] Embodiment 2: preparation of inorganic superhydrophobic material

[0057] (1) Cleaning the sample: Sonicate a soda lime glass sheet with a size of 50×30×0.5 mm in deionized water and acetone for 30 min in sequence.

[0058] (2) Vacuuming: the sample is placed in a vacuum chamber, and the vacuum chamber of the magnetron sputtering equipment is evacuated to a vacuum degree of 3×10 through the pumping system. -3 Pa.

[0059] (3) Preparation of Cu film with micro / nano structure: feed Ar gas into the vacuum chamber, keep the Ar flow rate at 30sccm, keep the working pressure in the vacuum chamber at 0.8Pa, adopt magnetron sputtering to discharge the Cu target, the purity of the Cu target It is 99.8% pure, the size is 145×100×6mm, and the power density of the control power supply is 80W / cm 2 , the deposition rate is controlled at 800nm / min.

[0060] (4) Cu / Cu 2 O / CuO micro-nanostructure surface preparation: the micro-nanostructure Cu film prepared by magnetron sputtering w...

Embodiment 3

[0061] Embodiment 3: Preparation of inorganic superhydrophobic material

[0062] (1) Clean the sample: Sonicate a 304 stainless steel sheet with a size of 50×30×0.5 mm in deionized water and acetone for 30 minutes.

[0063] (2) Vacuuming: the sample is placed in a vacuum chamber, and the vacuum chamber of the magnetron sputtering equipment is evacuated to a vacuum degree of 3×10 through the pumping system. -3 Pa.

[0064] (3) Preparation of Cu film with micro / nano structure: feed Ar gas into the vacuum chamber, keep the Ar flow rate at 30sccm, keep the working pressure in the vacuum chamber at 0.8Pa, adopt magnetron sputtering to discharge the Cu target, the purity of the Cu target It is 99.8% pure, the size is 145×100×6mm, and the power density of the control power supply is 120W / cm 2 , the deposition rate is controlled at 1 μm / min.

[0065] (4) Cu / Cu 2 O / CuO micro-nanostructure surface preparation: the micro-nanostructure Cu film prepared by magnetron sputtering was oxid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com