A single-tube hydraulic shock absorber with a highly adaptive system and method thereof

An adaptive system, a technology of hydraulic shock absorbers, applied in the directions of gas-liquid shock absorbers, shock absorbers, shock absorbers, etc., can solve the problems of easy nodding of braking, simple structure, and stuck valve mechanism, etc. Achieving the effect of good wheel grip, compact structure and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

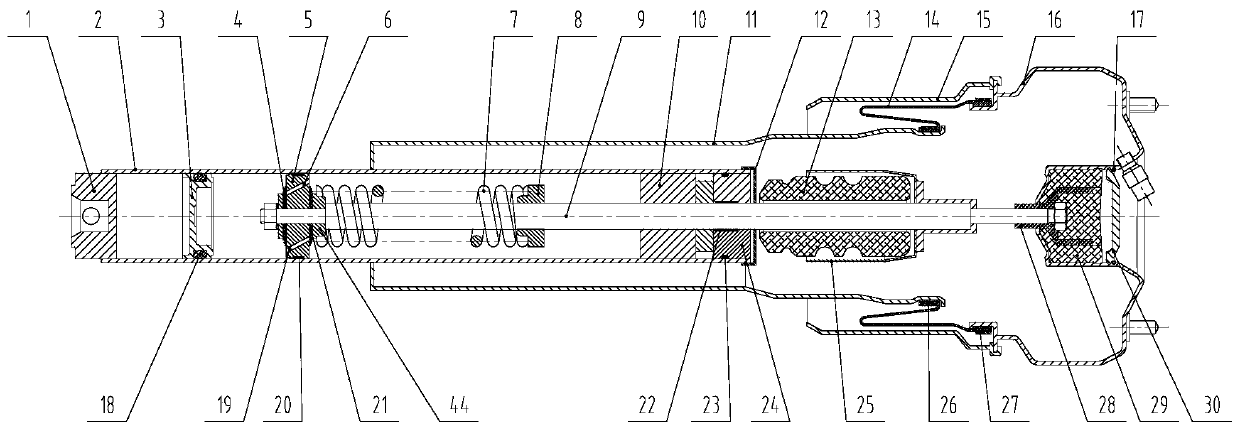

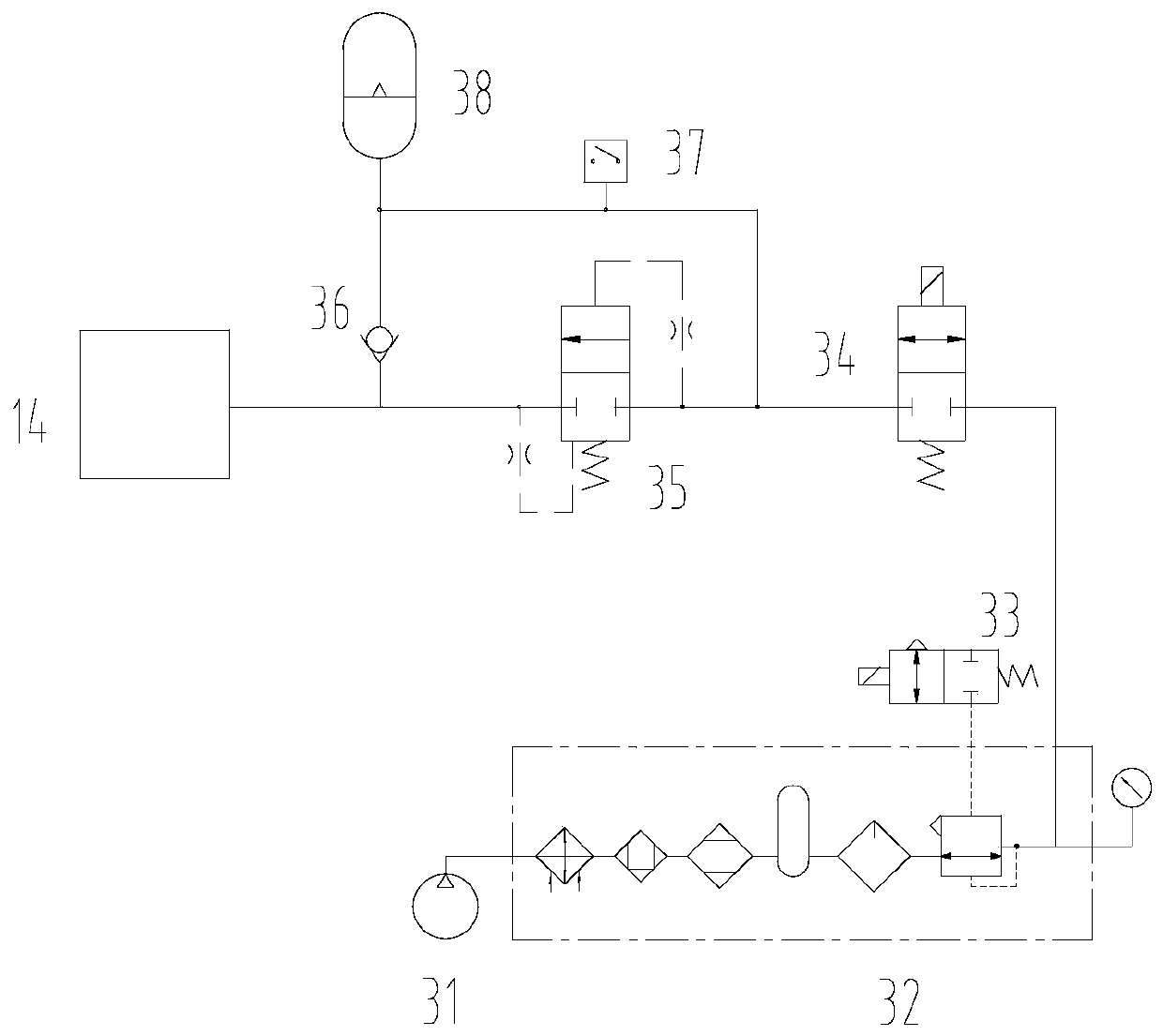

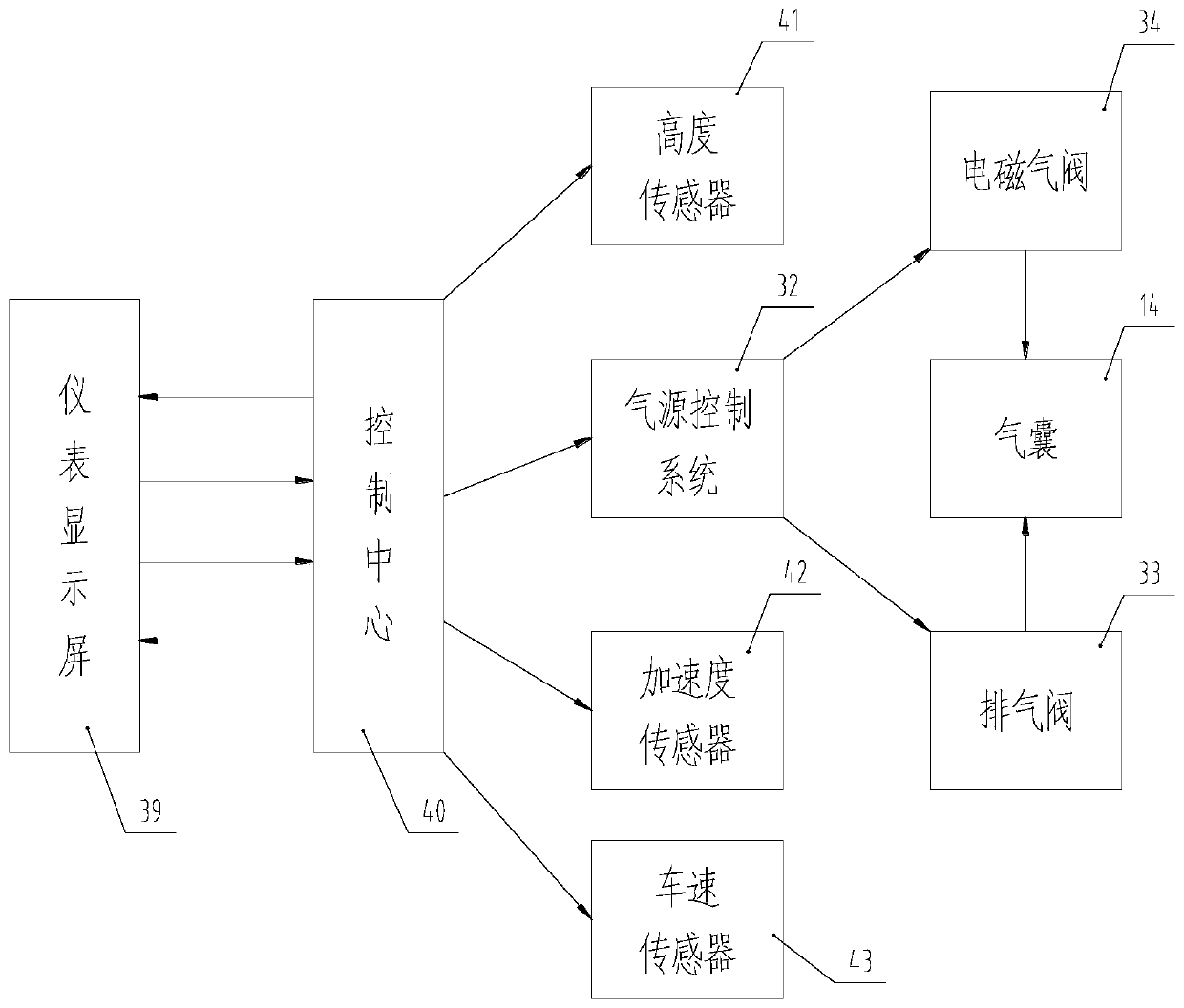

[0032] figure 1 Shown is an embodiment of the single-tube hydraulic shock absorber with a highly adaptive system of the present invention, and the single-tube hydraulic shock absorber with a highly adaptive system includes a single-tube hydraulic shock absorber and highly adaptive systems.

[0033] The single-tube hydraulic damping system includes a piston barrel 2, a piston plug 1 and a U-shaped end cap 12 that seal off the two ends of the piston barrel 2 by welding respectively; the piston barrel 2 includes a piston head 5, a piston rod 9 and a The spring 7 and the piston head 5 are fixed to one end of the piston rod 9 by bolts, and are coaxially installed in the piston barrel 2. The outer ring surface of the piston head 5 is equipped with a second seal 20 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com