Integral forming manufacture mold with matching rock structural surface upper and lower plates

A technology of integral molding and structural surface, applied in the engineering field, can solve the problems of poor flatness of contact surface, complicated process, poor surface performance of structural surface, etc., achieve high flatness, avoid stress concentration effect, and uniform force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

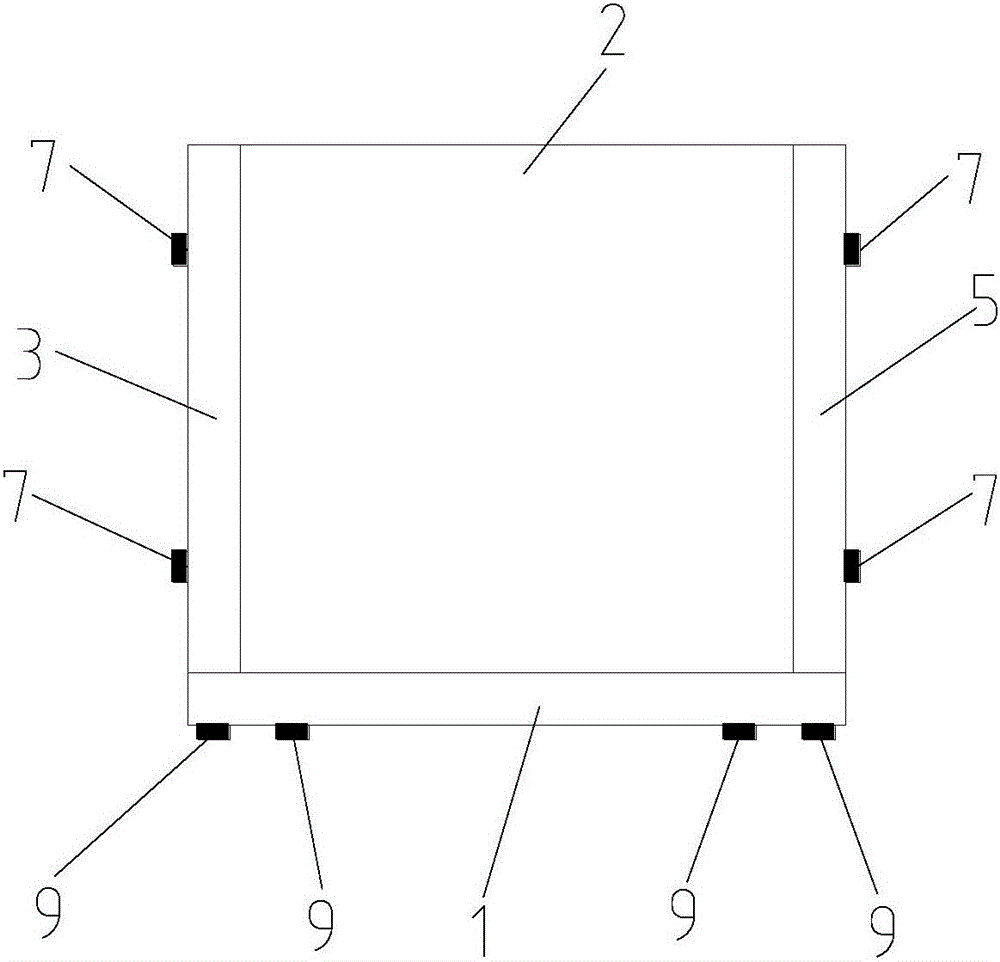

Image

Examples

Embodiment approach

[0073] 1) Select the morphology of the upper and lower wall structural surfaces. According to the test requirements, the irregular sawtooth structure surface is selected, the undulation angle of a single sawtooth is uncertain, the slope height is 5mm, and the number of sawtooth is calculated according to the test requirements.

[0074] 2) The assembly of the irregular zigzag structural surface formwork of the upper and lower plates. Place the selected upper plate structural surface formwork 601 and lower plate structural surface formwork 602 vertically first, and then put their flat sides against each other, and at the same time ensure that the bolt holes 603 on the upper and lower plate structural surface formworks are aligned with each other. Insert and tighten the fixing bolts 8 of the upper and lower plate structural surface templates to complete the assembly of the upper and lower plate irregular zigzag structural surface templates.

[0075] 3) Installation of the irregu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com