Sample pretreatment method and pesticide residue detection method for fruit and vegetable pesticide residue detection

A technology for sample pretreatment and pesticide residue detection, which is applied to chemical instruments and methods, measuring devices, and other chemical processes, can solve the problems of limiting the speed of sample pretreatment, and achieve the goals of saving operating time, reducing losses, and shortening time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

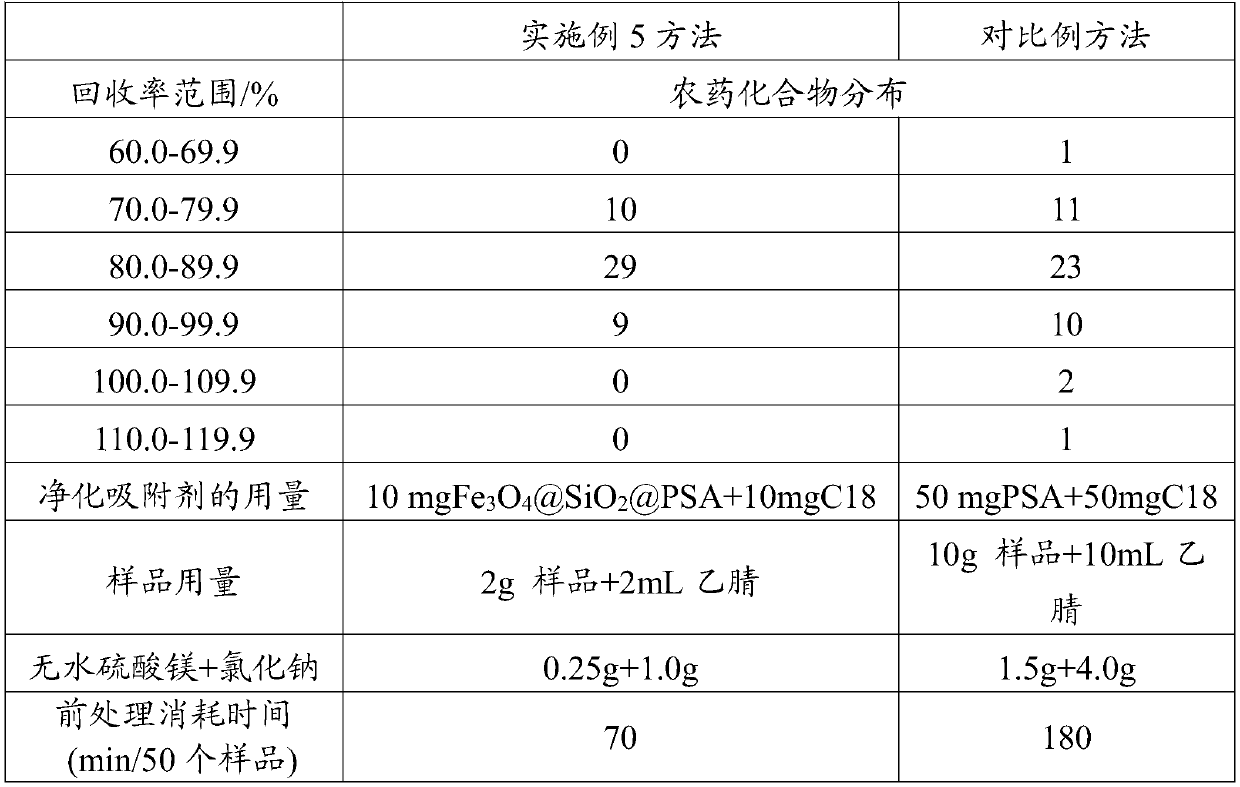

[0031] The present invention has no special limitation on the preparation method of the purification adsorbent, it only needs to mix the components described in the above technical solution according to parts by weight. The Fe contained in the purification adsorbent of the present invention 3 o 4 @SiO 2 @PSA is a kind of magnetic nanoparticle, so that the purification adsorbent can be adsorbed by the magnetic field, so the purification adsorbent provided by the present invention can be separated from solid and liquid without centrifugation after adsorption, the adsorption efficiency is high, and the steps of sample pretreatment can be simplified , saving operating time.

[0032] The present invention also provides a method for sample pretreatment when applying the purified adsorbent described in the above technical scheme to detect pesticide residues in fruits and vegetables, comprising the following steps:

[0033] (1) mixing the fruit and vegetable homogenate sample to be...

Embodiment 1

[0050] Crush and homogenize the green vegetables, weigh 2.00 g of the above-mentioned green vegetable homogenate sample, add azoxystrobin standard product, make the concentration of azoxystrobin in the sample to be tested be 100 μg / kg, and let it stand for 30 minutes. Weigh 2.00 g of the spiked green vegetable homogenate sample and mix with 2.00 ml of acetonitrile, vortex for 1 min to obtain the first mixture; mix with 0.35 g of sodium chloride and 1.4 g of anhydrous magnesium sulfate, and vortex for 1 min to obtain the second mixture ; The second mixture was mixed with 60mg purification adsorbent, vortexed for 0.5min to obtain a magnetic adsorption mixture, and the purification adsorbent was composed of 10mg Fe 3 o 4 @SiO 2 Composed of @PSA and 50mg graphitized carbon black; under the action of an external magnetic field, the magnetic adsorption mixture is separated from solid and liquid, absorb 0.5ml supernatant extract and mix with 0.5ml water, filter with 0.22μm microporo...

Embodiment 2

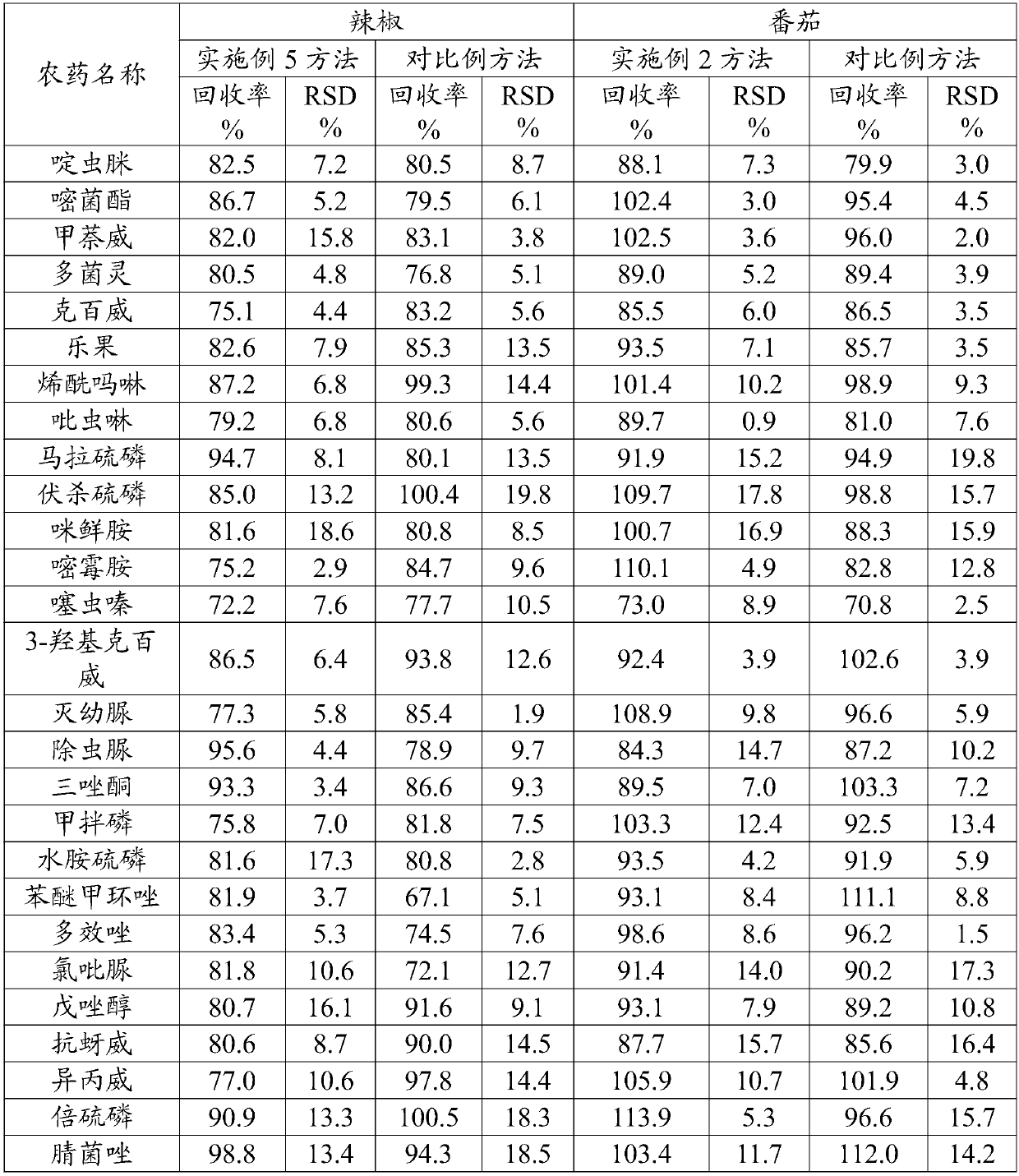

[0054] Crush and homogenize the tomato, weigh 2.00 g of the tomato homogenate sample, add a standard triadimefon to make the concentration of triadimefon in the sample to be tested 100 μg / kg, and let it stand for 30 minutes. Weigh 2.00 g of the tomato homogenate sample after adding the standard and mix with 2.00 ml of acetonitrile, vortex for 1 min to obtain the first mixture; mix with 0.3 g of sodium chloride and 1.2 g of anhydrous magnesium sulfate, and vortex for 1 min to obtain the second mixture ; The second mixture is mixed with 10mg purification adsorbent, and vortexed for 0.5min to obtain a magnetic adsorption mixture, and the purification adsorbent is composed of 10mg Fe 3 o 4 @SiO 2 @PSA composition; under the action of an external magnetic field, the magnetic adsorption mixture is separated from solid to liquid, absorb 0.5ml of supernatant extract and mix with 0.5ml of water, filter with 0.22μm microporous membrane, and the obtained filtered solution is the sample ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com