Glass furnace temperature forecast method based on learning machine related to Gaussian mixture distribution

A technology of mixing Gaussian and glass furnace, applied in the field of automatic control, can solve the problems of low prediction accuracy, poor generalization ability, strong uncertainty, complex asymmetric noise, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

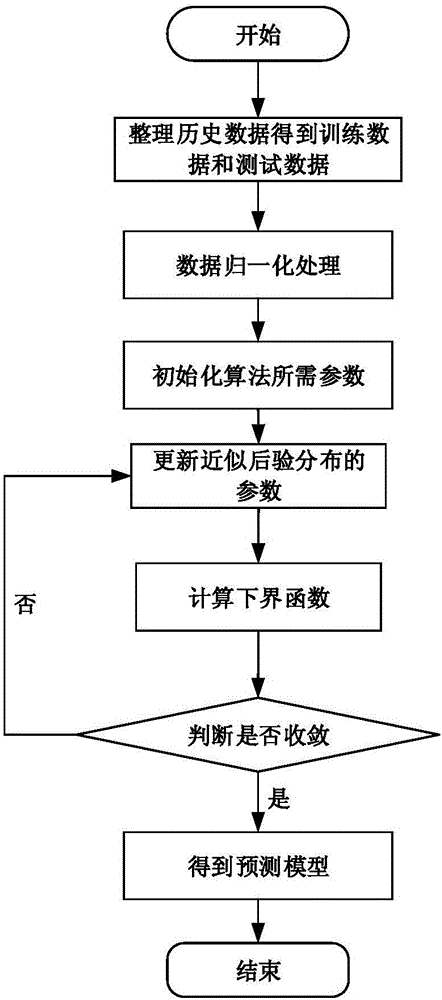

[0075] In order to better understand the technical scheme of the present invention, figure 1 The algorithm flowchart of the present invention is given in .

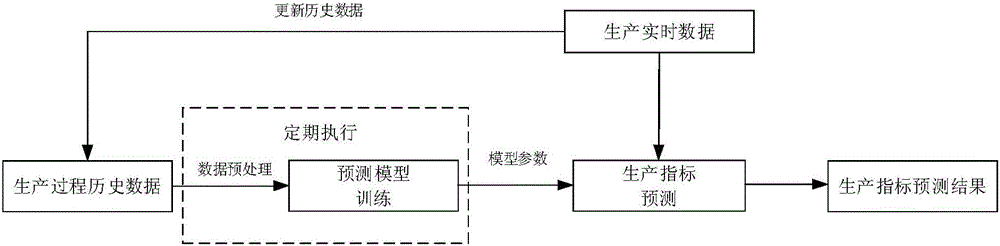

[0076] Take a certain large-scale glass production enterprise as an example to illustrate the implementation process of the present invention, the flow chart of this implementation process is shown in figure 2 . Firstly, relevant data are collected from the MES system and database of the company's glass furnace production line. Then perform data preprocessing, such as input feature selection, time-lag selection, filling missing data, etc. then follow figure 1 The algorithm flow shown is to train the model to obtain the parameters of the forecast model. When the index forecast is required, the current model input is passed to the production index forecast module, and the final model prediction value is obtained through calculation. Since the actual production process changes in real time, the model needs to be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com