A method of suppressing the accumulation of electric charge on the surface of electric equipment

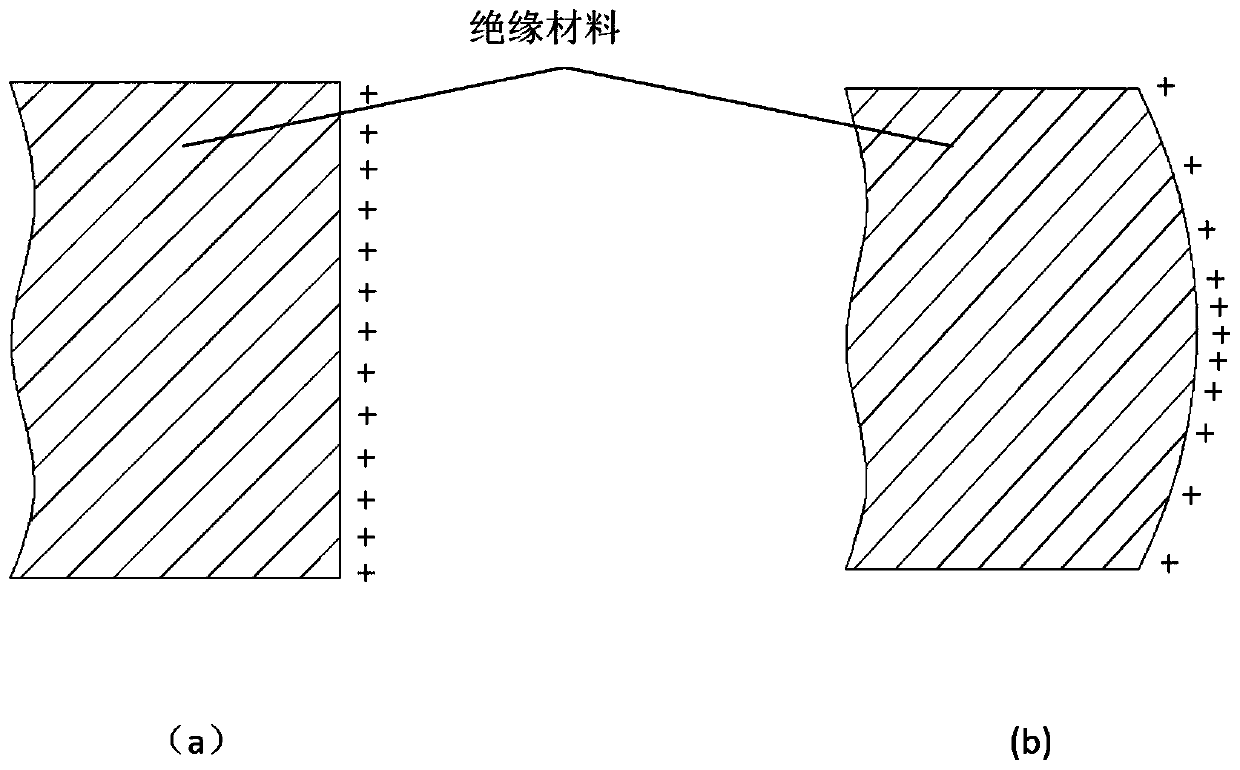

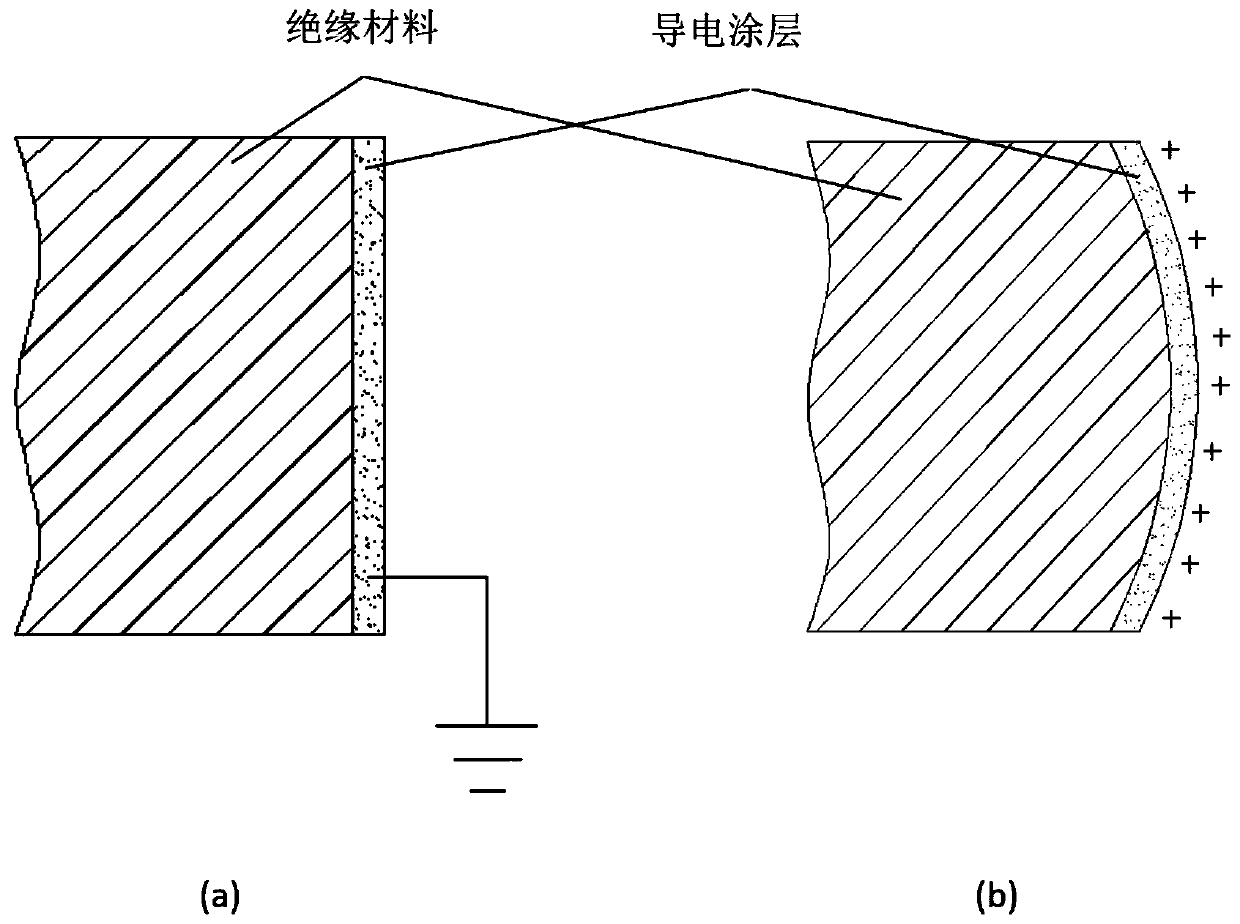

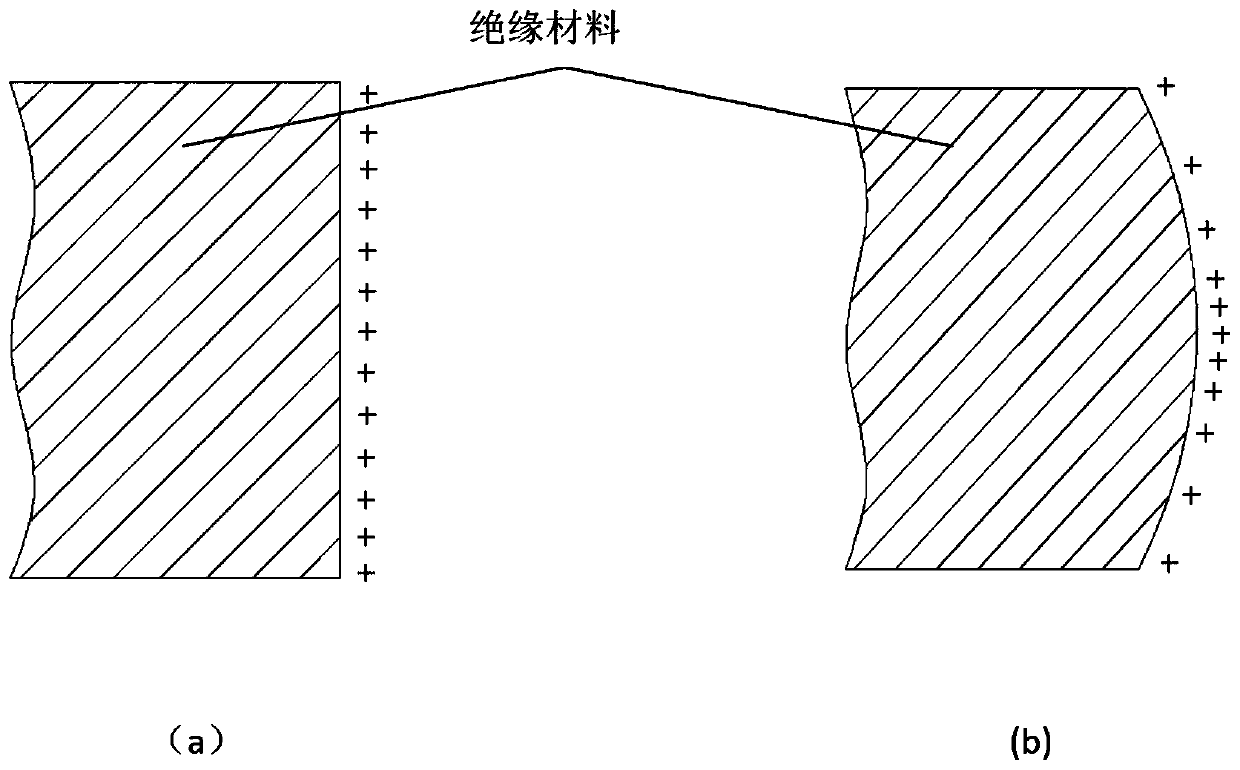

A technology of electric equipment and surface charge, applied in the direction of connecting contact materials, etc., can solve problems such as flashover, distortion of electric field distribution along the surface, and charge accumulation on the surface of supporting insulators, so as to prevent electrostatic shock, avoid electric field distortion, and reduce surface flashover network effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The present invention will be further described below in conjunction with accompanying drawing:

[0028] 1) When preparing liquid metal, according to the chemical composition of gallium-indium alloy in different proportions, weigh gallium metal and indium metal with a purity of 99.99% according to the mass ratio, and put the weighed two metals into the same beaker, Heat at 100°C until it melts evenly into a liquid state. Stir the mixture for 5 min with a magnetic stirrer or ultrasonically for 1 h in a water bath at 40° C. to ensure uniform mixing of the two to obtain a crude liquid metal gallium indium alloy.

[0029] 2) After that, put the gallium-indium alloy in the beaker, and then slowly add a 30% NaOH solution. Put the beaker on a magnetic stirrer and stir for 2h to remove the oxides generated by the alloy during the preparation process. After the reaction was complete, the gallium-indium alloy material in the beaker sank to the bottom of the beaker, while the so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com