Presulfurized hydrodesulfurization catalyst and preparation method thereof

A hydrodesulfurization and catalyst technology, applied in the direction of physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve the problem of low activity of hydrodesulfurization catalysts, poor controllability, high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The present invention also provides a preparation method of a presulfided hydrodesulfurization catalyst, the preparation method comprising the following steps:

[0033] (1) impregnating the gamma-alumina carrier in a mixture containing urea, a water-soluble salt of metal component A and water, and obtaining a modified alumina carrier through heat treatment, filtration, washing and drying;

[0034] (2) Using a solution C containing a water-soluble salt of the metal component B, a sulfur source and a dilute acid as the impregnation solution, the modified alumina carrier obtained in step (1) is impregnated, heat-treated, and then carried out in an inert gas Drying, roasting, among them,

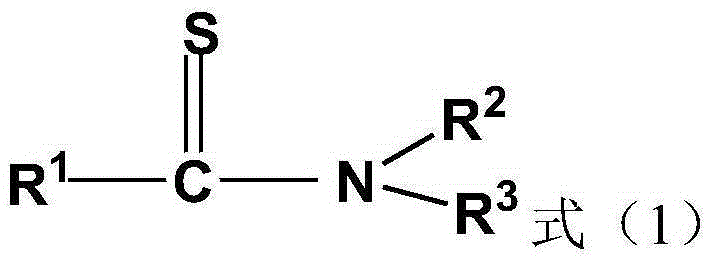

[0035] Metal component A is at least one of the metal elements selected from Group VIII, metal component B is at least one of the metal elements selected from Group VIB, and the sulfur source can be at 50-100 °C, Sulfur-containing substances hydrolyzed under acidic conditions.

[0036] ...

Embodiment 1

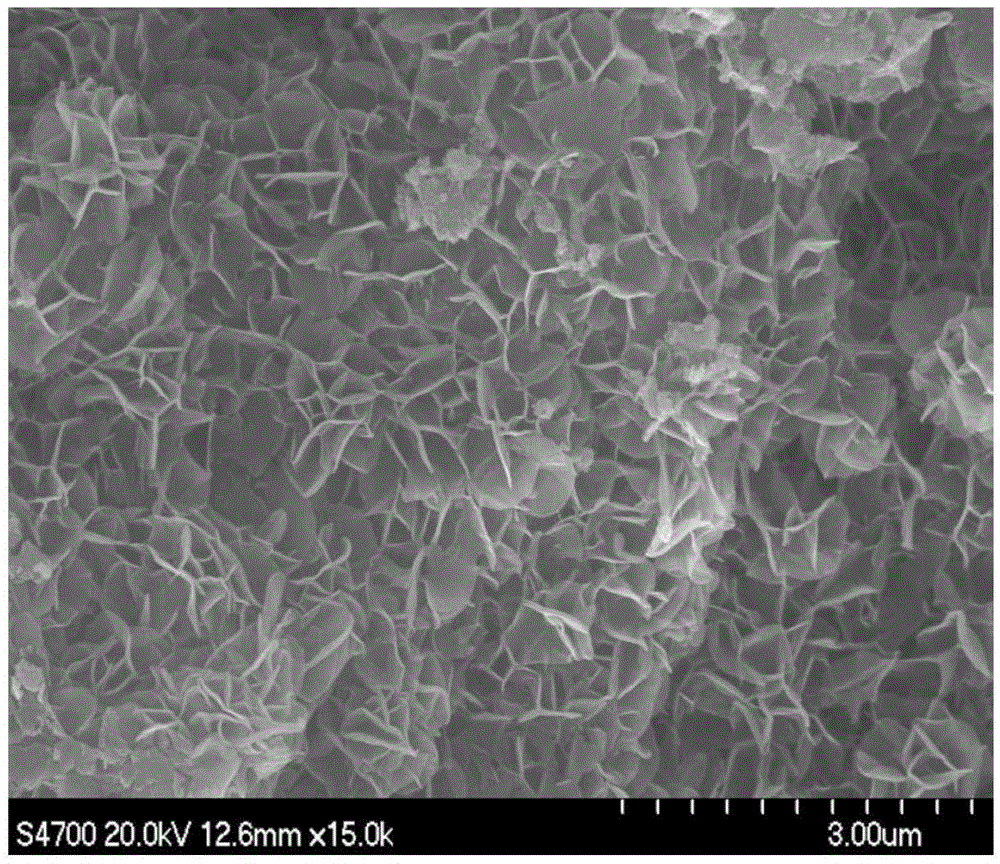

[0074] (1) 50.0g of γ-Al with a diameter of 2-5mm 2 o 3 The granules were immersed in 250.0 mL of a mixed aqueous solution containing 0.8 mol / L cobalt nitrate, 1.6 mol / L urea, and 0.32 mol / L ammonium chloride, heat-treated at 80°C for 24 hours, filtered, washed and then dried at 100°C for 6 hours to obtain Co-modified alumina support, the SEM image of the Co-modified alumina support is as follows figure 1 shown. From figure 1 It can be seen that the surface of the Co-modified alumina support has a large number of network structures, and the network density is listed in Table 1.

[0075] (2) Prepare 60 mL of aqueous solution containing 0.1 mol / L of sodium molybdate, 6 mL of absolute ethanol and 0.3 mol / L of thioacetamide, and adjust the pH of the solution to pH=6.5 with 1.5 mol / L of nitric acid to obtain solution C , weighed 4.0 g of the Co-modified alumina support obtained in step (1), immersed it in solution C for 1 hour, then treated it in a transposed oven (100 rpm) at ...

Embodiment 2

[0078] (1) 50.0g of γ-Al with a diameter of 2-5mm 2 o 3 The granules are immersed in 250.0 mL of a mixed aqueous solution containing 0.4 mol / L nickel nitrate, 1.2 mol / L urea, and 0.4 mol / L ammonium nitrate, heat-treated at 90°C for 12 hours, filtered, washed and then dried at 150°C for 2 hours to obtain Ni-modified alumina support, the grid density of the Ni-modified alumina support is listed in Table 1.

[0079] (2) Prepare 60 mL of aqueous solution containing 0.1 mol / L of sodium molybdate, 30 mL of absolute ethanol and 0.4 mol / L of thioacetamide, and adjust the pH of the solution to pH=4.5 with 2.4 mol / L of hydrochloric acid to obtain solution C , Weigh 4.0g of the Ni-modified alumina carrier obtained in step (1), immerse it in solution C for 1 hour, then treat it in a transposed oven (100rpm) at 75°C for 12h, filter, wash, Dry at 80°C for 6 hours in a nitrogen atmosphere, and then bake at 400°C for 6 hours in a nitrogen atmosphere to obtain catalyst S-2.

[0080] The ana...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com