Method for preparing natural-flavor caramel by using red date processing wastes

A technology of waste and caramel, which is applied in the field of flavored caramel preparation, can solve the problems of waste of active ingredients, waste of jujube pit and jujube skin, and unstudied flavor caramel, and achieve the effect of high-efficiency utilization and natural flavor source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

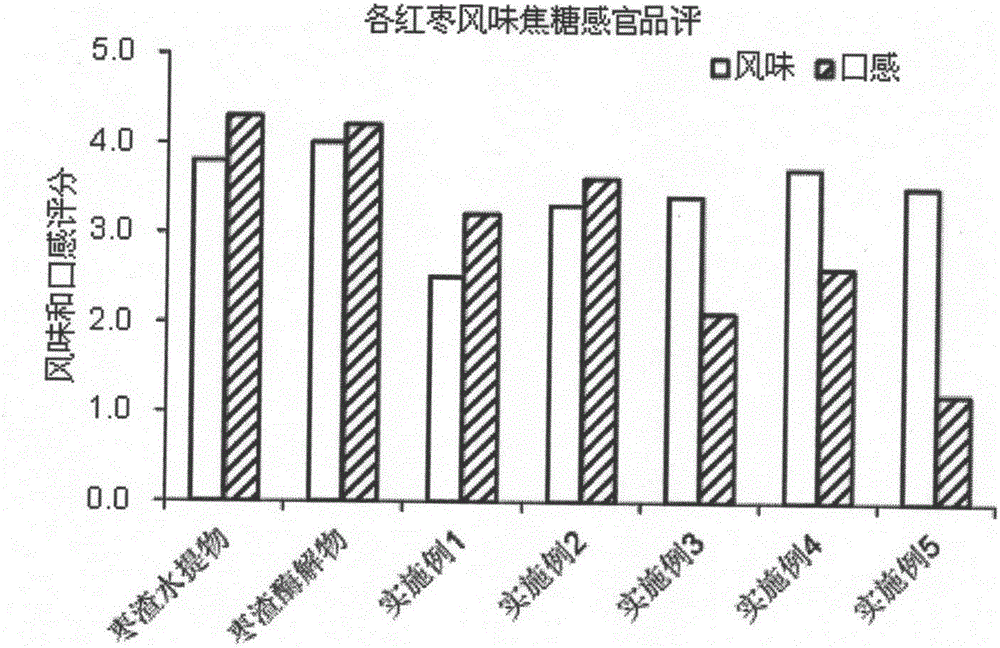

Examples

Embodiment 1

[0025] Step 1: Add 300 g of the dried and pulverized jujube dregs mixture into a 5L stainless steel stirring reactor, add 2700 g of water, and adjust the solid content of the system to 10%;

[0026] Step 2: Use 30% NaOH solution to adjust the pH to 5.0, and extract at 90°C for 5 hours. After the extract is filtered through a plate and frame, 2.4 kg of the supernatant is obtained and stored for later use;

[0027] Step 3: take by weighing 2.7kg fructose syrup (fructose content 42%, solid content 70%) in the reactor;

[0028] Step 4: Add 300 g of jujube dregs aqueous extract, and adjust the pH to 4.5;

[0029] Step 5: heat up to 121°C, pressure 0.1MPa, and react for 1 hour to obtain caramel syrup with jujube flavor, which is light brown in color and has no coloring function.

Embodiment 2

[0031] Step 1: get the filtered residue in Example 1, and measure its water content to be 51%;

[0032] Step 2: Weigh 600g of wet filter residue, add 1656g of water to adjust the system to a solid content of 15%, and a pH value of 4.8;

[0033] Step 3: Add pectinase (produced by Shanghai Mazy Company) and cellulase (produced by Denmark Novo Company) mixture (mixing ratio 1:3) with an enzyme addition of 0.3% of the dry material, and enzymatically hydrolyze at 50 ° C for 8 hours;

[0034] Step 4: After the reaction, heat up to 90°C, inactivate the enzyme for 15 minutes, filter and store 1.7kg of the supernatant for later use, and store the filter residue after drying;

[0035] Step 5: Weigh 2.85 kg of fructose syrup (fructose content 42%, solid content 70%) in the reactor, add 150 g of jujube dregs enzymatic hydrolysis solution, and adjust the pH to 4.5;

[0036] Step 6: heat up to 121° C., pressure 0.1 MPa, and react for 1 hour to obtain caramel syrup with jujube flavor. The s...

Embodiment 3

[0038] Step 1: Add 600 g of the dried and pulverized jujube dregs mixture into a 5L stainless steel stirring reactor, add 2400 g of water, and adjust the solid content to 20%;

[0039] Step 2: adjust the pH to 5.0 with 30% NaOH solution, and extract at 90°C for 5 hours;

[0040] Step 3: After the extract is filtered through a plate and frame, 1.7 kg of the supernatant is obtained and stored for later use;

[0041] Step 4: Weigh 2.70kg of glucose solution (70% solid content) in the reactor, and adjust the pH to 3.5;

[0042] Step 5: heat up to 150°C, pressure 0.55MPa, react for 7 hours;

[0043] Step 6: After the system cools down to 100°C, add 450g of jujube dregs extract through the feed port of the reactor;

[0044] Step 7: Keep warm for 1 hour at 121°C and pressure of 0.1MPa to prepare caramel syrup with rich jujube flavor. The color of the syrup is dark brown, and the color value after dilution 1000 times is 0.025, which has a certain coloring function.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com