Method for preparing PLGA (poly lactate glycollic acid)-magnesium mixture and method for manufacturing implant of orthopedics department

A mixture, plant technology, applied in medical science, tissue regeneration, prosthesis, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The method for preparing PLGA-magnesium mixture of the present invention, it adopts the following steps to carry out:

[0045] (1) Determine the total weight of the prepared PLGA-magnesium mixture as m, wherein the magnesium content is n% of the total weight;

[0046] (2) Weigh m×(100-n)% PLGA, and at the same time weigh m×n% high-purity magnesium powder with a purity of more than 99.9% for use;

[0047] (3) Add 12-20 times the weight of chloroform into the container holding the PLGA, and stir with a mixer to make the PLGA fully dissolve in the chloroform;

[0048] (4) Let the mixture stand, and when the chloroform volatilizes and the mixture becomes dense, add the weighed magnesium powder, stir well to make it evenly mixed;

[0049] (5) Place the mixed viscous mixture on the sample plate for air drying;

[0050] (6) The obtained sample was dried in a vacuum oven to obtain a PLGA-magnesium mixture product containing n% magnesium by weight.

[0051] In the above metho...

Embodiment A

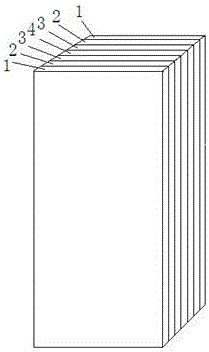

[0084] The first layer contains 1% by weight of magnesium, the second layer contains 5% by weight of magnesium, the third layer contains 10% by weight of magnesium, the fourth layer contains 5% by weight of magnesium, and the fifth layer contains 5% by weight of magnesium 1%.

Embodiment B

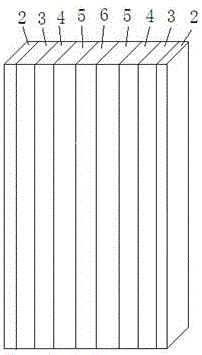

[0086] The first layer contains 2% magnesium by weight, the second layer contains 7% magnesium by weight, the third layer contains 15% magnesium by weight, the fourth layer contains 30% magnesium by weight, and the fifth layer contains magnesium by weight The percentage is 15%, the sixth layer contains 7% by weight of magnesium, and the seventh layer contains 2% by weight of magnesium.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com