Multi-parameter subsection optimized novel rotating disc extraction column

A rotary disk extraction tower, multi-parameter technology, applied in solvent extraction, liquid solution solvent extraction, separation methods, etc., to achieve the effects of increasing mixing intensity, suppressing axial back-mixing, and high mass transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

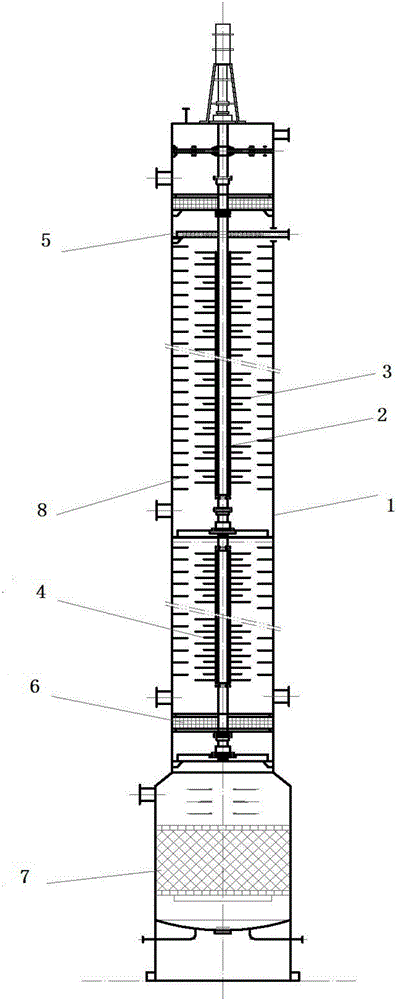

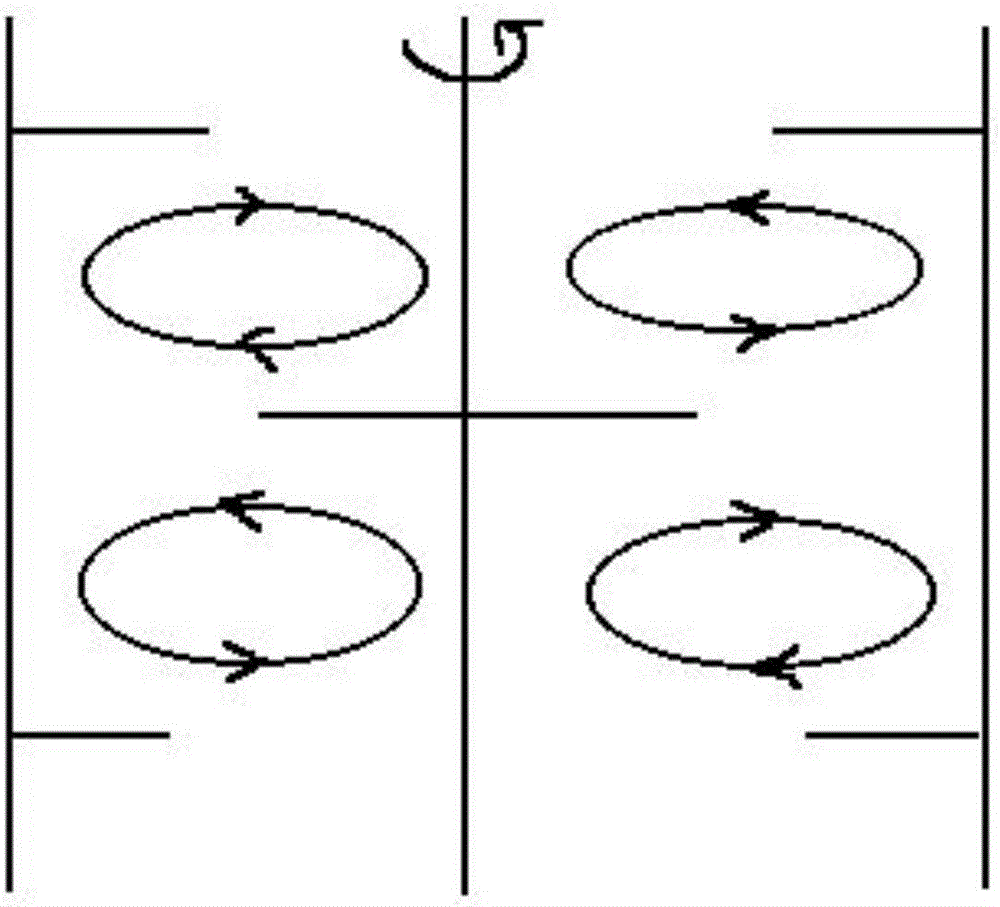

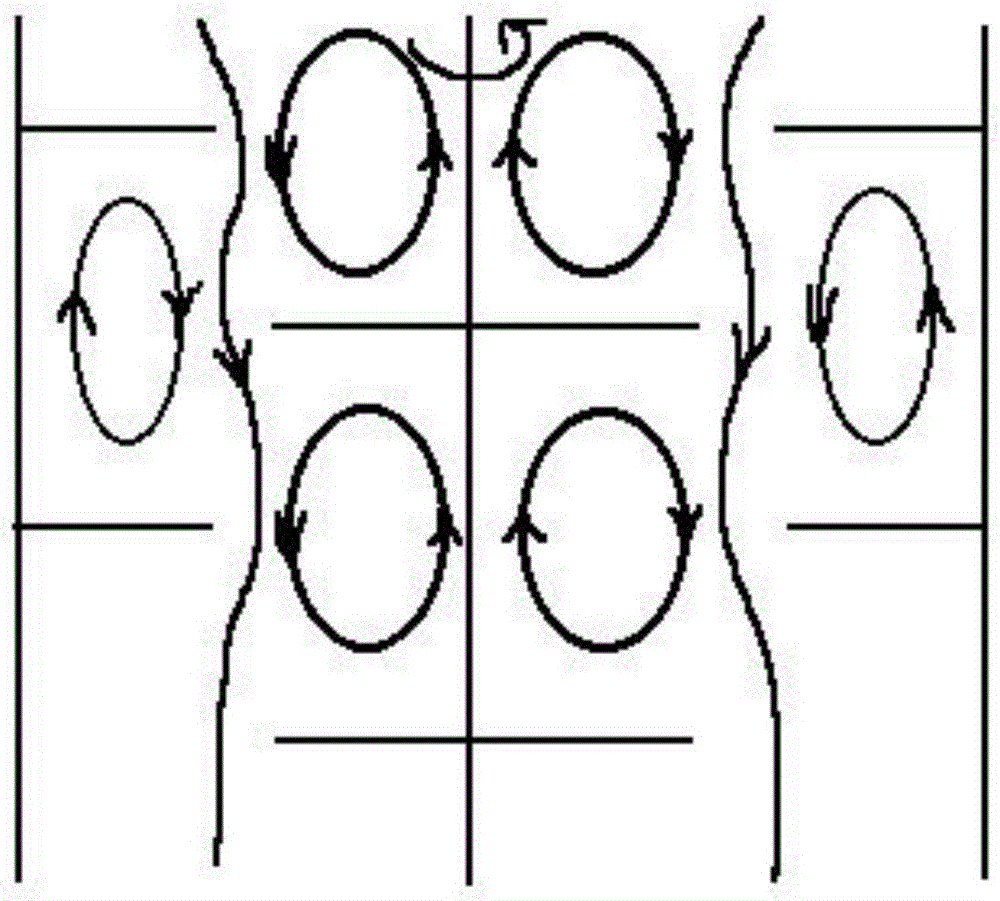

[0030] see Figure 1-5 , a novel rotary disk extraction tower with multi-parameter subsection optimization, including a tower body 1, a rotating shaft 2, a rotary disk 3, a rotating sieve baffle 4, a liquid distributor 5, a filter layer 6 and a fixed ring 8. The tower body 1 The interior is hollow, the fixing ring 8 is arranged on the inner wall of the tower body 1, the rotating shaft 2 is fixedly installed on the center position of the rotating shaft fixing plate, the rotating shaft 2 fixing plate is fixedly installed in the tower body 1, and the rotating sieve baffle 4 Fixed on the rotating shaft 2, the rotating screen hole baffle plate 4 rotates with the rotating shaft 2; the plane where the rotating screen hole baffle plate 4 is located is consistent with the plane where the fixing ring 8 is located; The rotating sieve baffle 4 is spaced apart, and the diameter of the rotary plate 3 is larger than the diameter of the rotating sieve baffle 4; the rotating sieve baffle 4 rot...

Embodiment 2

[0032] see Figure 1-5, a novel rotary disk extraction tower with multi-parameter subsection optimization, including a tower body 1, a rotating shaft 2, a rotary disk 3, a rotating sieve baffle 4, a liquid distributor 5, a filter layer 6 and a fixed ring 8. The tower body 1 The interior is hollow, the fixing ring 8 is arranged on the inner wall of the tower body 1, the rotating shaft 2 is fixedly installed on the center position of the rotating shaft fixing plate, the rotating shaft 2 fixing plate is fixedly installed in the tower body 1, and the rotating sieve baffle 4 Fixed on the rotating shaft 2, the rotating screen hole baffle plate 4 rotates with the rotating shaft 2; the plane where the rotating screen hole baffle plate 4 is located is consistent with the plane where the fixing ring 8 is located; The rotating sieve baffle 4 is spaced apart, and the diameter of the rotary plate 3 is larger than the diameter of the rotating sieve baffle 4; the rotating sieve baffle 4 rota...

Embodiment 3

[0034] see Figure 1-5 , a novel rotary disk extraction tower with multi-parameter subsection optimization, including a tower body 1, a rotating shaft 2, a rotary disk 3, a rotating sieve baffle 4, a liquid distributor 5, a filter layer 6 and a fixed ring 8. The tower body 1 The interior is hollow, the fixing ring 8 is arranged on the inner wall of the tower body 1, the rotating shaft 2 is fixedly installed on the center position of the rotating shaft fixing plate, the rotating shaft 2 fixing plate is fixedly installed in the tower body 1, and the rotating sieve baffle 4 Fixed on the rotating shaft 2, the rotating screen hole baffle plate 4 rotates with the rotating shaft 2; the plane where the rotating screen hole baffle plate 4 is located is consistent with the plane where the fixing ring 8 is located; The rotating sieve baffle 4 is spaced apart, and the diameter of the rotary plate 3 is larger than the diameter of the rotating sieve baffle 4; the rotating sieve baffle 4 rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com