Multi-beam laser interference micro-nano processing device and method based on Dammann grating and reflectors

A Damman grating, micro-nano processing technology, applied in laser welding equipment, metal processing equipment, optics, etc., can solve the performance of lens processing error beam splitter, uneven light intensity distribution of interference fringes, complex process and difficult to achieve, etc. problems, to achieve the effect of convenient adjustment of the optical path, controllable processing size, and improved convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

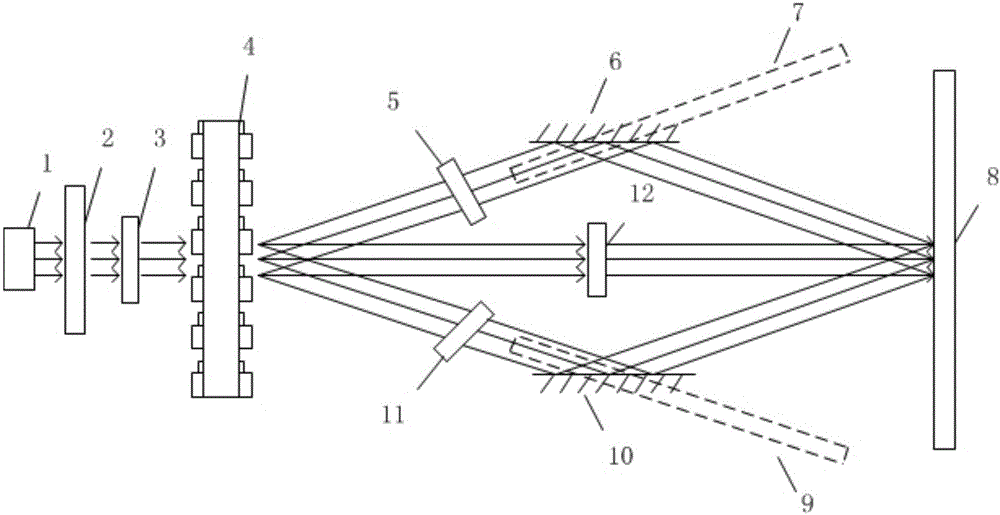

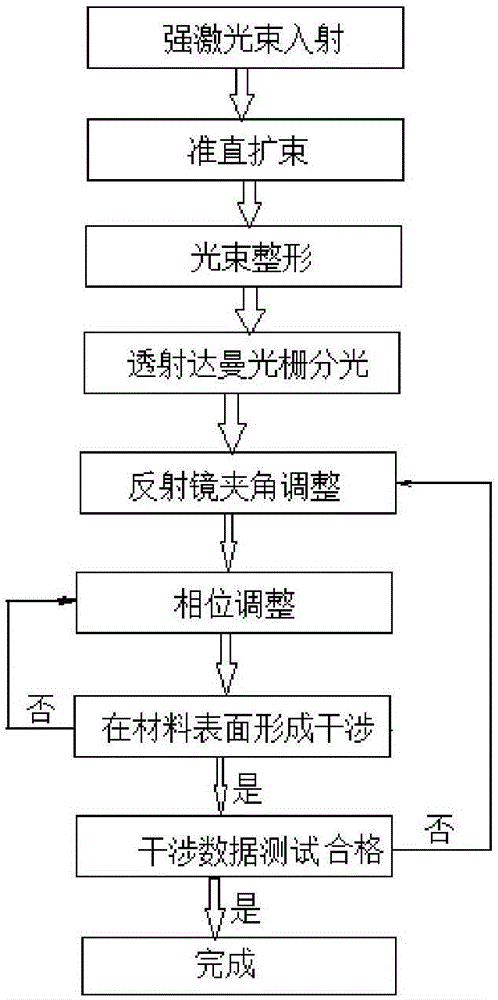

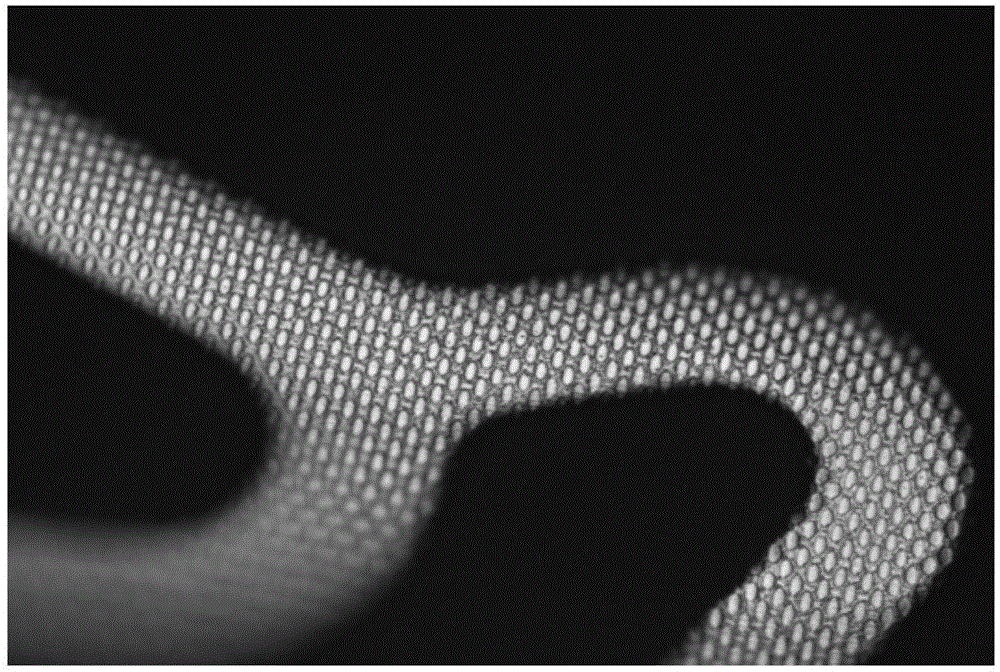

[0025] A pulsed laser is used as the light source, and the beam first passes through a collimated beam expander system and a beam shaper, and then the exposure time is controlled by a shutter. The laser beam emitted by the laser is divided into multiple beams of coherent light after being transmitted through the double-layer Damman grating. A grating, which can divide the incident plane light wave of a single wavelength into several equal light intensity distributions in the far field. When in use, the laser light emitted by the laser is divided into +1 level, 0 level and -1 level three beams through the transmission grating, and then phase modulates the +1 level, 0 level and -1 level three beams of light respectively, and then separates them on both sides. Set up a slideway with a reflector, use the movement of the reflector on the slideway to adjust the angle of multi-beam interference and select the processing cycle, so as to realize the convergence interference of multiple...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| etching depth | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com