Bimetallic composite plate welding method

A welding method and composite plate technology, applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve the problems of low welding seam welding efficiency, increased cladding deposition amount, complicated process, etc., and achieve the improvement of cladding The effect of welding efficiency, reduction of cladding deposition amount, and simple groove form

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] In this embodiment, the (15+3)mm UNS N08825 / L450MS hot-rolled nickel-based composite plate is taken as an example for welding, and the size of the welded test plate is 200×600mm.

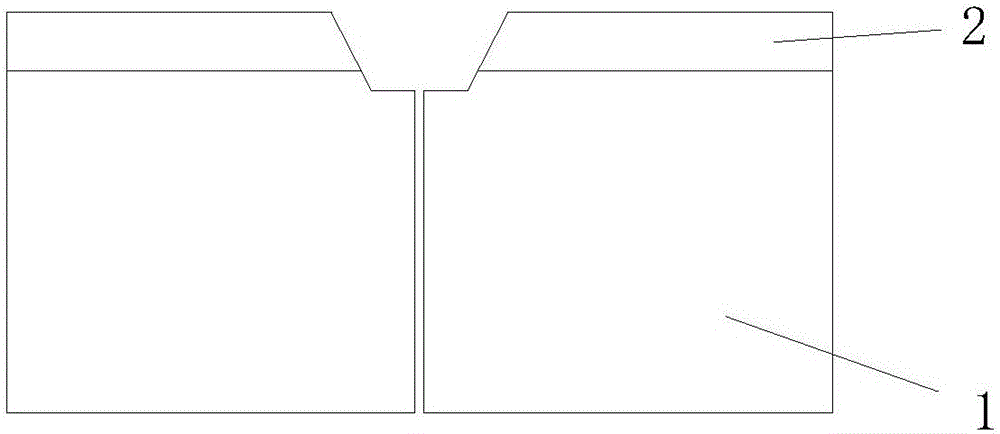

[0027] Step 1: Make I-type and V-type grooves on the welding test plate, such as figure 1 As shown, the specific dimensions are: the thickness of the base layer 1 is 15mm, the thickness of the compound layer 2 is 3mm, the height of the I-shaped groove is 14mm, the angle of the V-shaped groove is 60°, and the width of the bottom of the V-shaped groove is 4mm.

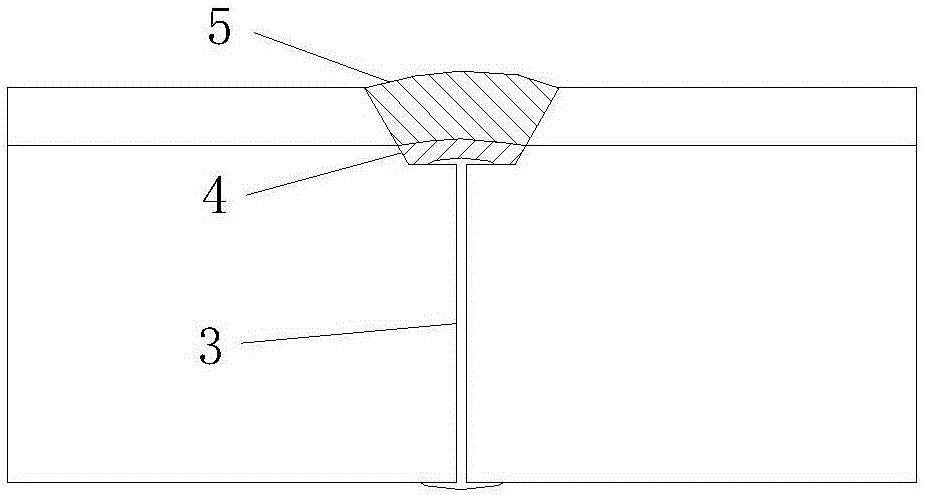

[0028] Step 2: Butt the welding test plates, and use laser welding to weld the I-shaped groove without filler wire. The distance between the two plates is not greater than 0.5mm, and the specific welding parameters are shown in Table 1. Use an angle grinder to clean the base weld 3 stainless steel side to create good welding conditions for transitional layer welding.

[0029] Step 3: TIG is used to perform welding on the base welding ...

Embodiment 2

[0040] In this embodiment, the (6+2)mm 2205 / L450MS explosion+rolled composite plate is taken as an example for welding, and the size of the welding test plate is 200×600mm.

[0041] Step 1: Make I-type and V-type grooves on the welding test plate, such as figure 1 As shown, the specific dimensions are: the thickness of the base layer 1 is 6mm, the thickness of the compound layer 2 is 2mm, the height of the I-shaped groove is 5mm, the angle of the V-shaped groove is 60°, and the width of the bottom of the V-shaped groove is 4mm.

[0042] Step 2: Butt the welding test plates, and use plasma welding to weld the I-shaped groove without filling wire. The distance between the two plates shall not be greater than 0.5mm. Use an angle grinder to clean the base weld 3 stainless steel side to create good welding conditions for transitional layer welding.

[0043] Other steps are the same as in Example 1.

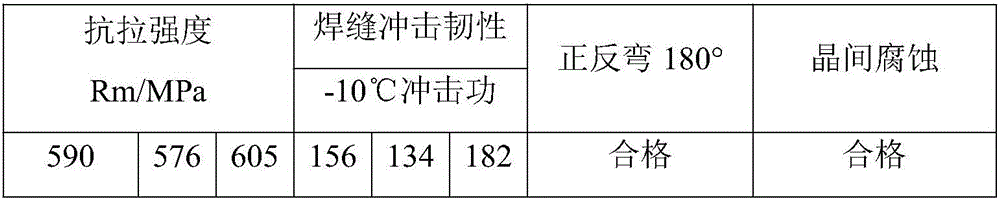

[0044] The welding parameters of the base layer are shown in Table 4, and the w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com