Production technology of environment-friendly lead sheath with scales

A production process and environmental protection technology, applied in fishing accessories, fishing, animal husbandry, etc., can solve problems such as unfavorable production efficiency and production qualification rate, difficulty in grasping the trimming length of lead skin, poor uniformity of lead skin thickness, etc. , to achieve the effect of avoiding touching heavy metals, good environmental protection effect, and avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

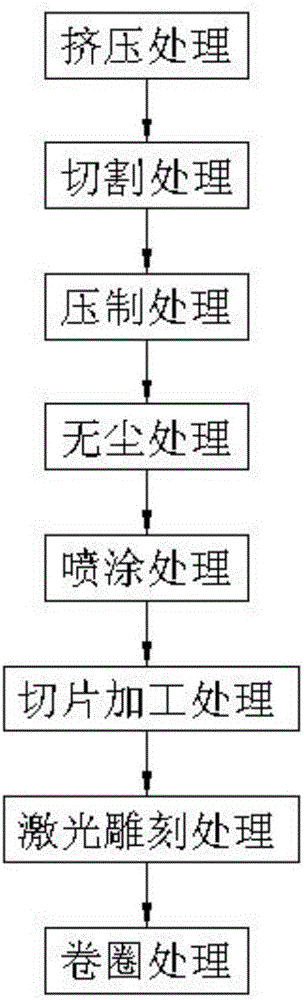

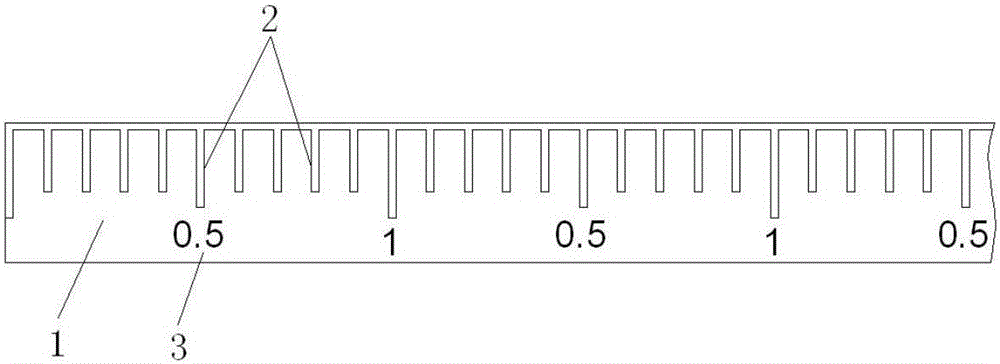

[0027] like Figure 1 to Figure 2 Shown, a kind of production technique of the environment-friendly lead skin with scale, this production technique comprises the following steps:

[0028] (1) Extrusion treatment: the lead ingot with a lead content of 99.997% is extruded into a lead plate with a thickness of 1 cm;

[0029] (2) cutting process: the lead plate that step (1) is made is carried out cutting processing, lead plate is cut into the lead sheet of some different widths;

[0030] When above-mentioned step (2) carries out cutting process, according to the required lead sheet width parameter in the actual production process, lead plate is carried out cutting process;

[0031] (3) Squeeze treatment: Carry out the first pressing operation first, carry out pressing process to the lead flake that step (2) is made with the roller of 100 tons,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com