Embedded measurement and control system and method for guiding robot intelligent grasping

A robot intelligence, measurement and control system technology, applied in the field of robots, can solve the problems of supplementary light source without visual sensor, difficult application in industrial sites, poor real-time performance, etc., to simplify image processing algorithms, shorten development cycle, and facilitate development and debugging Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

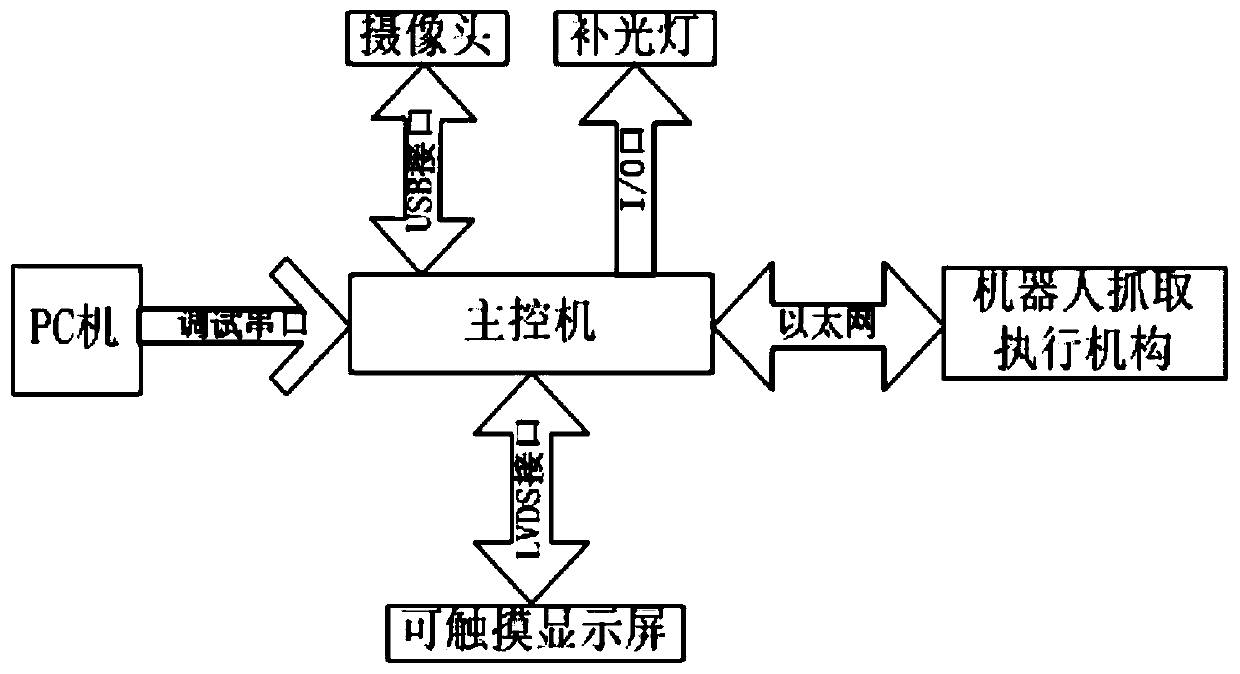

[0036] like figure 1 As shown, the embedded measurement and control system used to guide the intelligent grasping of the robot mainly includes an embedded ARM11 processor, a camera sensor module, a supplementary light source and a touchable display.

[0037] The embedded ARM11 processor is the core component of the system. Since the system is built on the basis of the ARM processor, it can transplant the mature OPENCV library. The image processing algorithm can be completed with the help of the OPENCV library, and the open source, easy-to-cut, and real-time Linux system is used. , easy to develop and debug, easy to popularize and use.

[0038] The embedded ARM11 processor is preferably the Samsung ITOP4412 core processor with strong comprehensive performance. It is a quad-core processor based on the Cortex-A9 core with a maximum frequency of 1.6GHZ. Deal with real-time requirements.

[0039] The embedded ARM11 processor is connected to the camera sensor module through the US...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com