Wheel type diamond knife scribing method

A diamond knife and scribing technology, which is applied in the direction of fine working devices, manufacturing tools, stone processing equipment, etc., can solve the problem of reducing the luminous efficiency of LED dies, the technology of laser scribing is not very mature, and the influence of optical performance of photosensitive devices, etc. problems, achieve good market application prospects, improve scribing quality and efficiency, and reduce scribing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

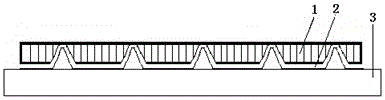

[0034] A wheel type diamond knife scribing technology, comprising the following steps:

[0035] 1) Preparation: thin the SiC wafer to the target thickness of 60um and complete the backside process;

[0036] 2) Film attachment: use UV film to fix the SiC sheet that has completed the back process on the stretch ring;

[0037] 3) Scribing: Place the SiC wafer to be scribed on the MDI LS831 wheeled diamond scribing machine, vacuum it firmly, and scribing under the conditions of pressure 0.1~0.2MPa and speed 10~50mm / s;

[0038] 4) Fragmentation: Place the scribed SiC wafer on the Dynatex cleavage machine, set the hoof knife to coincide with the scratch setting and keep it still, set the pressure knife to the blank position of the scribing groove and press down 0.03~0.2mm for 50~300ms Then lift it up to complete a split action, repeat the above action until all scratch splits are completed;

[0039] 5) Fragmentation: Use a film expander to expand the chip spacing after the lobes, ...

Embodiment 2

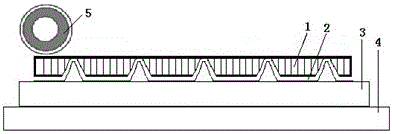

[0041] The wheel type diamond knife scribing method comprises the following steps:

[0042] 1) Preparation: thin the GaN wafer to the target thickness of 100um and complete the backside process;

[0043] 2) Film: use blue film to fix the GaN flakes that have completed the back process on the stretch ring;

[0044] 3) Scribing: Place the GaN wafer to be scribed on the MDI LS831 wheeled diamond scribing machine, vacuum it firmly, and scribing under the conditions of pressure 0.15~0.35MPa and speed 10~200mm / s;

[0045] 4) Fragmentation: Place the scribed GaN wafer on the Dynatex fragmentation machine, set the hoof knife and the scratch setting to keep it still, set the pressure knife to the blank position of the scribing groove and press down 0.05~0.2mm for 100~200ms Then lift it up to complete a split action, repeat the above action until all scratch splits are completed;

[0046] 5) Fragmentation: Use a film expander to expand the chip spacing after the lobes to prevent debri...

Embodiment 3

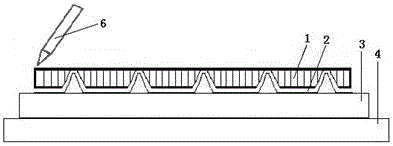

[0048] The wheel-type diamond knife scribing technology includes the following steps:

[0049] 1) Preparation: Thinning the sapphire wafer to the target thickness (usually 100um) and completing the backside process;

[0050] 2) Film: Use UV film to fix the sapphire sheet that has completed the back process on the stretch ring;

[0051] 3) Scribing: Place the sapphire wafer to be scribed on the MDI LS831 wheeled diamond scribing machine, vacuum it firmly, and scribing under the conditions of pressure 0.2~0.4MPa and speed 50~100mm / s;

[0052] 4) Fragmentation: Place the sapphire disc that has been marked on the Dynatex splitter, set the hoof knife and the scratch setting to keep it still, set the pressure knife to the blank position of the scribing groove and press down 0.05~0.1mm for 100~200ms Then lift it up to complete a split action, repeat the above action until all scratch splits are completed;

[0053] 5) Fragmentation: Use a film expander to expand the chip spacing aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com