Chassis cooling system for battery pack

A chassis cooling and battery pack technology, applied in secondary batteries, battery pack components, battery/battery traction, etc. Enhanced sealing, good heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

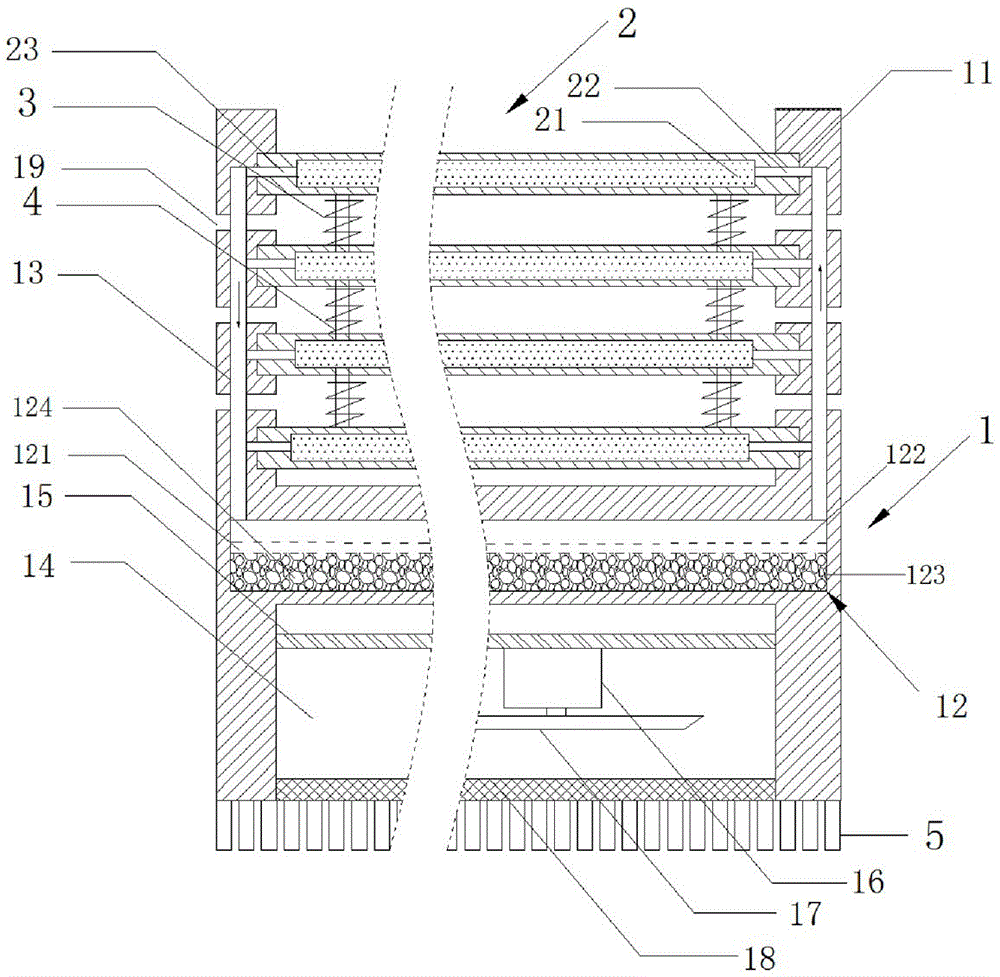

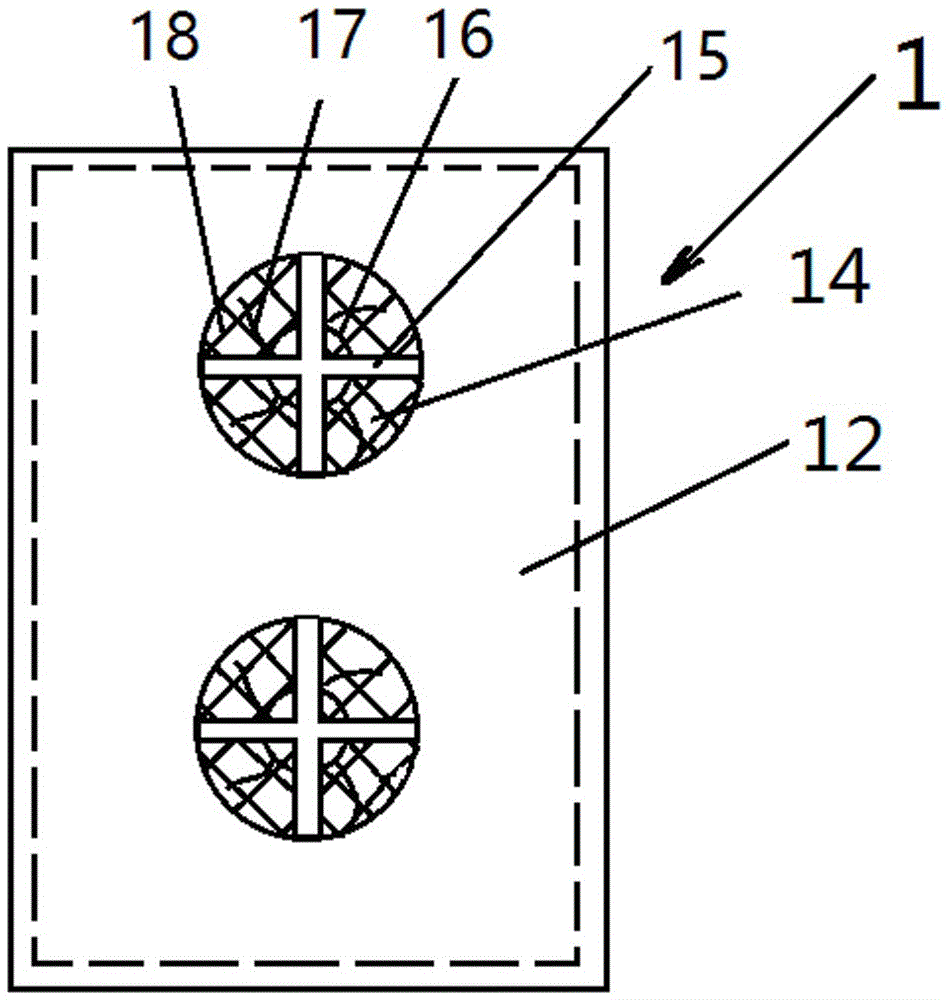

[0025] Such as figure 1 As shown, a battery pack chassis cooling system includes a chassis case 1 with an opening facing upwards and a plurality of battery pack separators 2. The inner wall of the chassis case 1 is provided with multiple slide grooves 11, and the battery pack partitions The plate 2 is inlaid inside the chute 11, and the inside of the battery pack separator 2 is provided with a liquid storage chamber 21 filled with a negative thermal expansion material, and a water inlet channel 22 and a water outlet channel 23 respectively communicating with the liquid storage chamber 21. The chassis shell 1 is provided with a cooling chamber 12 and a channel 13 communicating with the water inlet channel 22 and the water outlet channel 23 respectively. They are connected to form a cooling liquid passage, and the air bag 124 is filled in the coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com