Hybrid Electric Vehicle, Motor Drive Transmission System and Its Vibration Damping Mechanism

A vibration damping mechanism and motor-driven technology, which is applied to the arrangement of multiple prime movers of the power unit, the general power unit, and the air pressure power unit, etc., can solve problems such as reducing the service life of the product, damaging the transmission, and harming the human ear. , to prolong the service life, reduce noise and avoid harm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

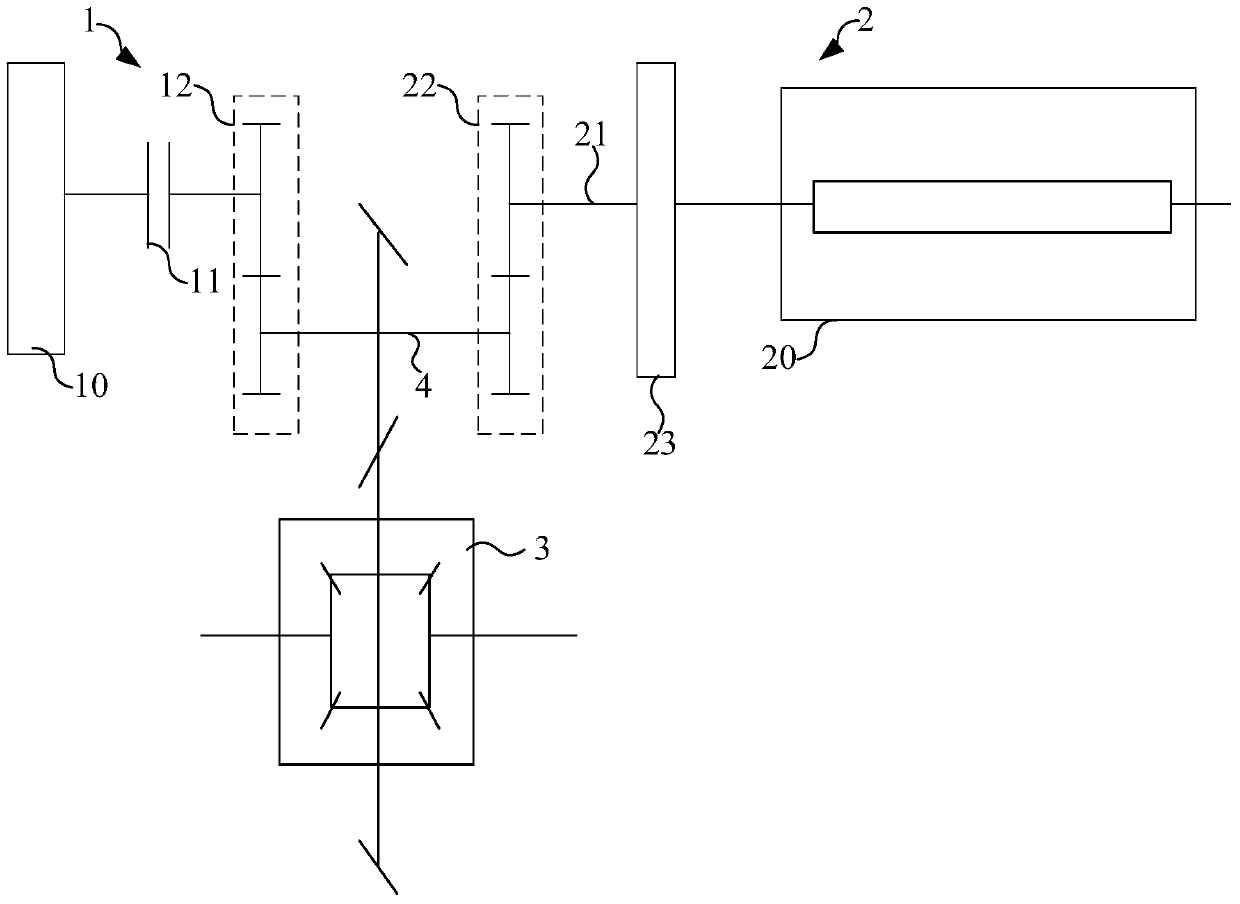

[0051] refer to figure 1 , the hybrid vehicle has two sets of power systems, which are the engine transmission system 1 and the motor drive transmission system 2 respectively. The motor drive transmission system 2 includes:

[0052] An electric motor 20, the electric motor 20 has a rotor and a stator (not shown in the figure), and both the rotor and the stator have several windings;

[0053] The intermediate shaft 21, the torque generated by the rotation of the rotor 2 is output to the final drive (not shown in the figure) and the differential 3 through the intermediate shaft 21 and the gear transmission mechanism 22 on the intermediate shaft 21;

[0054] The damping mechanism 23 is located between the intermediate shaft 21 and the rotor and is fixedly connected to the intermediate shaft 21 and the rotor respectively.

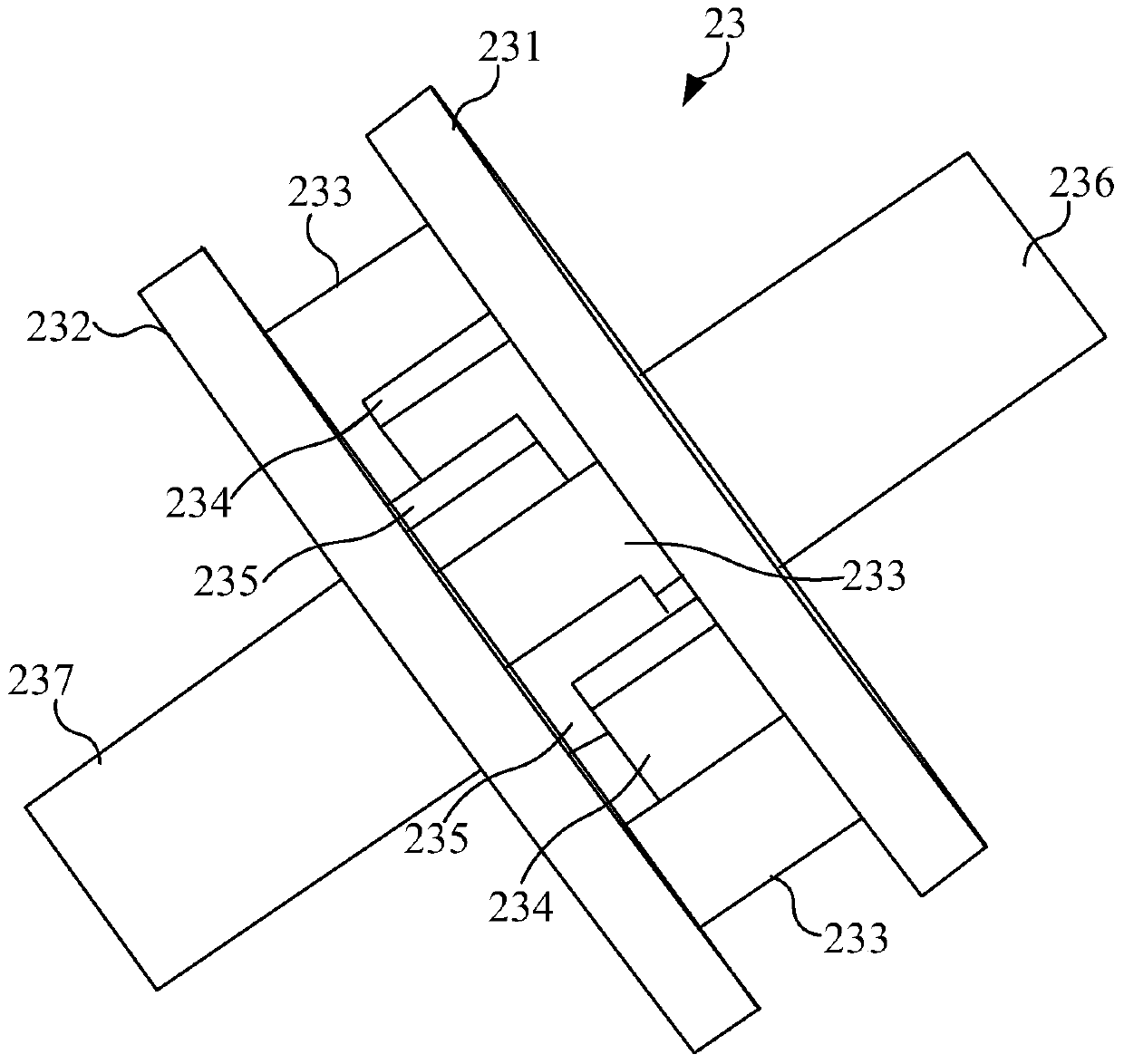

[0055] combined reference figure 2 , the damping mechanism 23 of this embodiment includes: a first support part 231, the first support part 231 is fixedly ...

no. 2 example

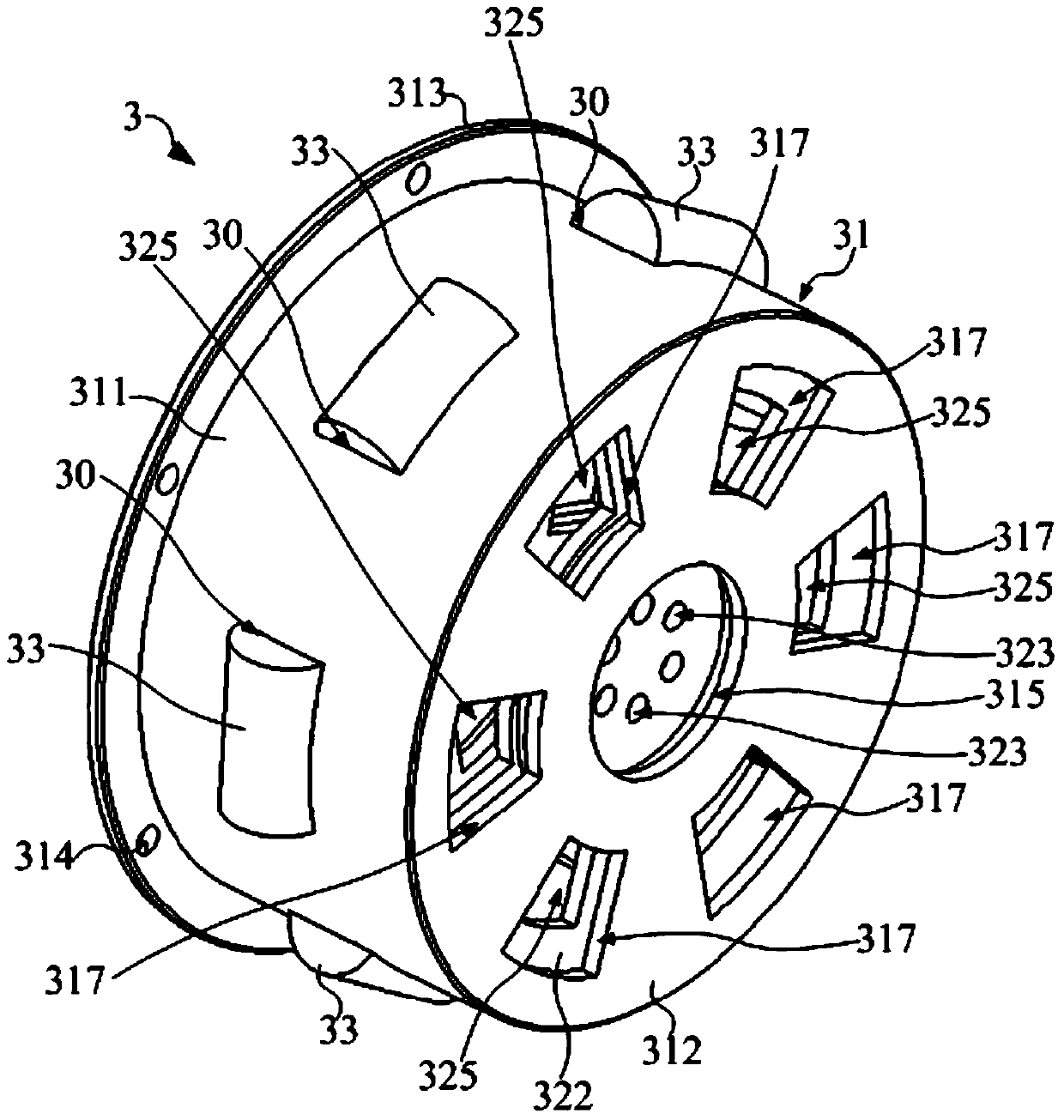

[0073] Unlike the first embodiment, refer to Figure 3 ~ Figure 5 , this embodiment is used in the damping mechanism 3 of the motor-driven transmission system, the first support part 31 includes a first ring part 311 and the second support part 32 includes a second ring part 321, and the first and second ring parts are the same The shaft is arranged on both sides along the axial direction of the first and second annular parts 311 and 321, one axial end of the first annular part 311 on one side is used to connect the intermediate shaft, and the second support part 32 on the other side is used for connecting the rotor;

[0074] The shock absorber 33 is connected between the first and second ring parts 311 and 321 and is used for extrusion deformation when the first support part 31 and the second support part 32 rotate relative to each other.

[0075] The first support part 31 can rotate around its own central axis relative to the second support part 32, and the shock absorber 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com