Single-phase automatic verification line technological layout

A technology of process layout and verification line, which is applied in the direction of conveyor objects, object stacking, object destacking, etc., can solve the problems of inability to work in parallel with multiple lines, low work efficiency, and affecting the production efficiency of electric energy meters, etc., to achieve Effect of improving utilization rate and production efficiency and improving production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

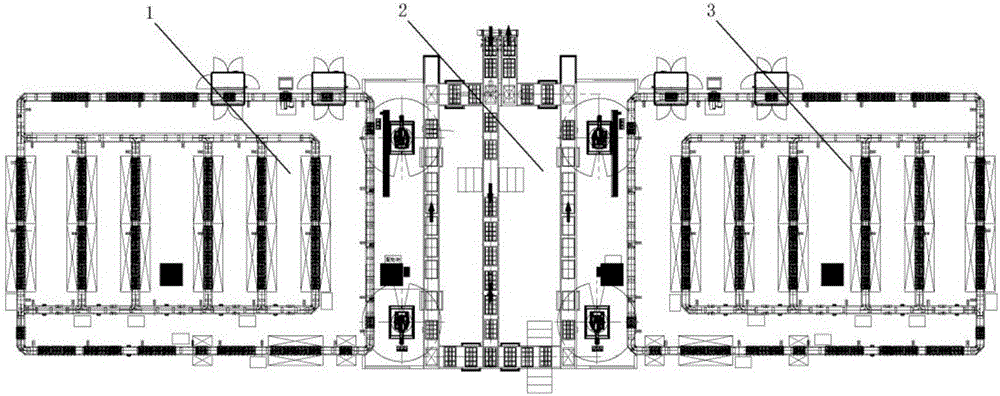

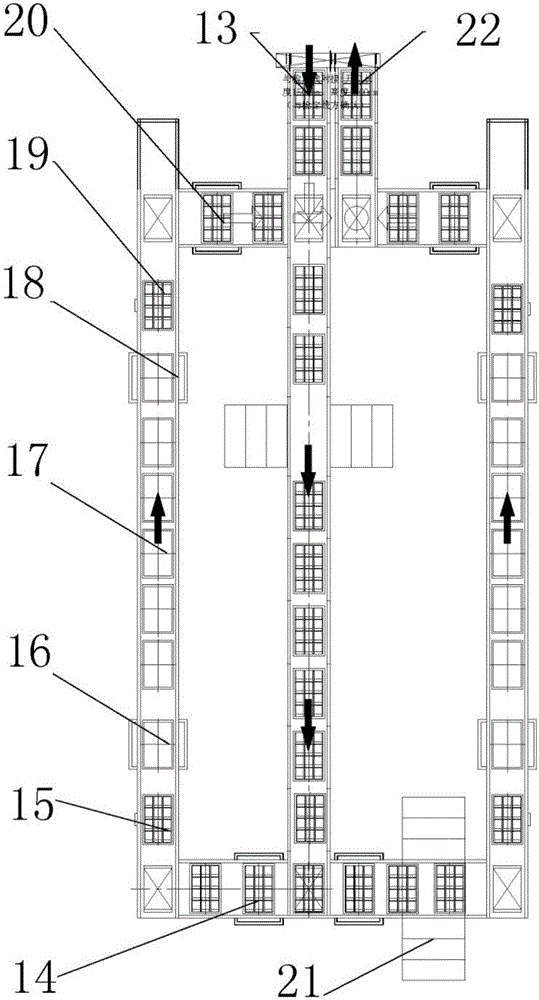

[0013] Example: such as figure 1 As shown, the process layout of the single-phase automatic verification line includes verification line A1, drum line 2, and verification line B3; a duplex parallel layout is adopted, and the drum line 2 is set between the verification line A1 and the verification line B3; the drum line 2 separates the materials Convey to the verification line A1 and verification line B3. After the verification line A1 and verification line B3 complete the scheduled tasks, the materials are put into the warehouse through the roller line 2.

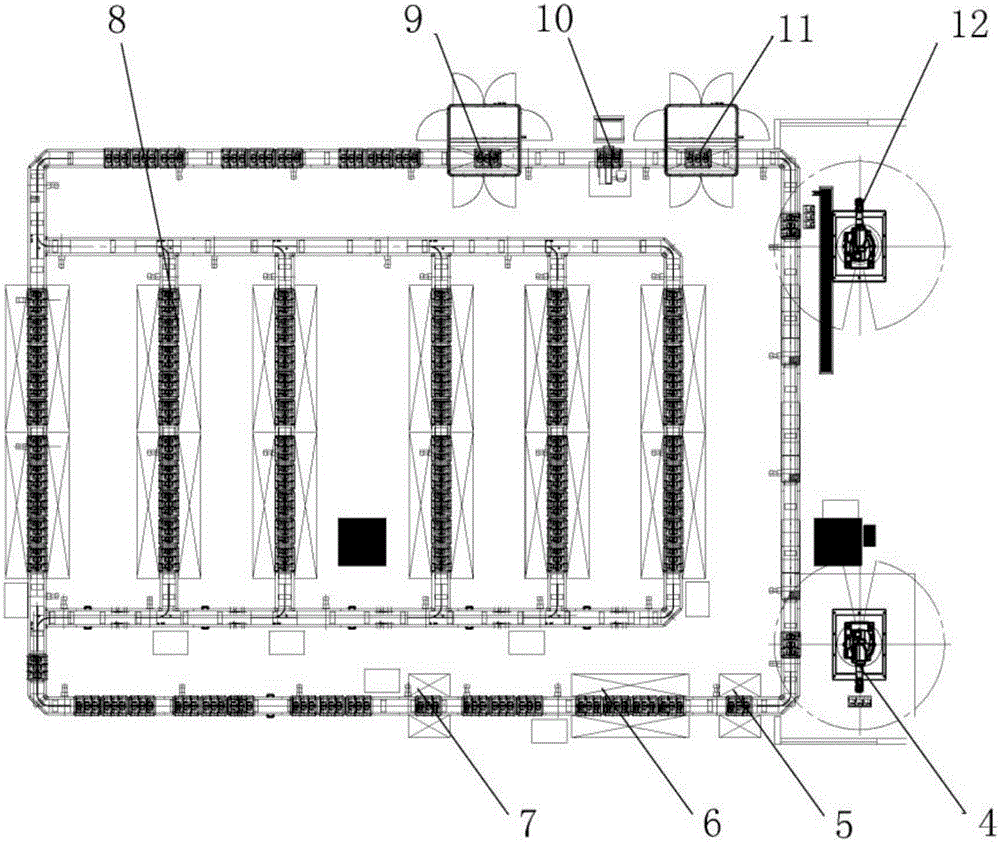

[0014] like figure 2 As shown, the process layout structure of verification line A1 and verification line B3 is the same, including feeding robot unit 4, information binding unit 5, pressure test unit 6, appearance inspection unit 7, multi-function verification unit 8, seal and verification unit 9. Laser marking unit 10, labeling and verification unit 11, and unloading robot unit 12; all units are connected into a closed-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com