High-speed tool steel welding rod and preparation method thereof

A high-speed tool steel, high-speed steel technology, applied in welding equipment, manufacturing tools, metal processing equipment and other directions, can solve the problems of unqualified electrode blanks and welding quality, to extend service life, improve production efficiency and utilization, solve The effect of market gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Measured in parts by weight, the selected powder is: 25 parts of marble, 10 parts of fluorspar, 3 parts of feldspar, 1 part of high-carbon manganese, 1 part of medium-carbon chromium, 2 parts of ferrovanadium, 4 parts of ferro-titanium, and 10 parts of titanium dioxide , 20 parts of rutile, 4 parts of zircon sand, 0.5 part of industrial silicon, 2 parts of mica, 1 part of soda ash, and mix the powder evenly.

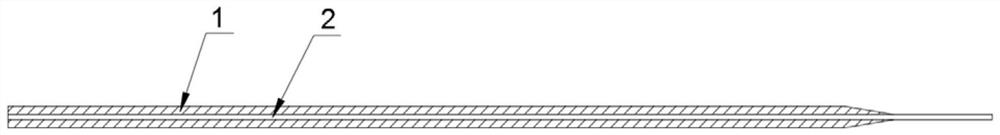

[0042] For every 100 parts by weight of the mixed powder, take 2.5 parts by weight of potassium sodium water glass and add it to the dry powder, mix evenly, press and apply it on the high-speed steel welding core with a Ф of 3.0mm, and dry it at low temperature for 12 hours. After drying at high temperature, high-speed tool steel electrodes (such as figure 1 , figure 2 shown).

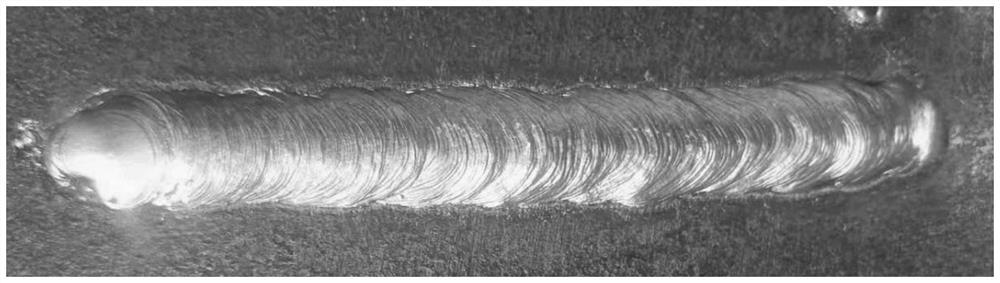

[0043] Use the high-speed tool steel electrode obtained in this embodiment for welding, and the welding current is 80-120A. The performance of the workpiece after welding is excellent,...

Embodiment 2

[0045]Measured in parts by weight, the selected powder is: 28 parts of marble, 11 parts of fluorite, 4 parts of feldspar, 1.5 parts of high-carbon manganese, 1.5 parts of medium-carbon chromium, 3 parts of ferrovanadium, 5 parts of ferro-titanium, and 12 parts of titanium dioxide , 23 parts of rutile, 5 parts of zircon sand, 0.7 part of industrial silicon, 2.5 parts of mica, 1.5 parts of soda ash, and mix the powder evenly.

[0046] For every 100 parts by weight of the mixed powder, take 3.0 parts by weight of potassium sodium water glass and add it to the dry powder and mix evenly, and apply it on the high-speed steel welding core with a Ф of 4.0 mm by using a hydraulic press, and dry it at low temperature for 12 hours. After high-temperature drying, high-speed tool steel electrodes are obtained.

[0047] Use the high-speed tool steel electrode obtained in this embodiment for welding, and the welding current is 150-180A. The performance of the workpiece after welding is exce...

Embodiment 3

[0049] Measured in parts by weight, the selected powder is: 27 parts of marble, 11 parts of fluorspar, 3.5 parts of feldspar, 1.5 parts of high-carbon manganese, 1 part of medium-carbon chromium, 2.5 parts of ferrovanadium, 4.5 parts of ferro-titanium, and 11 parts of titanium dioxide , 22 parts of rutile, 4 parts of zircon sand, 0.6 part of industrial silicon, 2.4 parts of mica, 1 part of soda ash, and mix the powder evenly.

[0050] For every 100 parts by weight of the mixed powder, take 3.0 parts by weight of potassium sodium water glass and add it to the dry powder, mix evenly, and apply it on the high-speed steel welding core with a Ф of 6.0mm with a hydraulic press, and dry it at low temperature for 12 hours. After high-temperature drying, high-speed tool steel electrodes are obtained.

[0051] Use the high-speed tool steel electrode obtained in this embodiment for welding, and the welding current is 190-220A. The workpiece after welding has excellent performance, stabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com