Continuous neutralizing production method of naphthalene water reducers or homology dispersers of naphthalene water reducers

A naphthalene-based water-reducing agent and a technology for a production method are applied in the field of continuous neutralization production for producing a naphthalene-based water-reducing agent or its homologous dispersant, and can solve the problem of increasing the total volume of the reactor, affecting the normal operation of the continuous reaction, and reducing the cost It can improve the utilization rate and production efficiency, reduce manual operation links, and be beneficial to product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The continuous neutralization production method of the present embodiment 1 naphthalene-based water reducer or its homologous dispersant comprises the following steps:

[0031] (1) Continuously pump the measured naphthalene-based water reducer or its homologous dispersant condensate into the neutralization device, and at the same time, send the measured soda ash slurry into the neutralization device for continuous neutralization reaction;

[0032] (2), the neutralized material in step (1) is overflowed from the neutralization device to the buffer tank for full reaction, and when the pH value of the material in the buffer tank is 7-9, the material is discharged to the subsequent drying device;

[0033] (3) The foam generated in the neutralization device overflows into the foam receiving tank through the overflow pipe, the foam is eliminated by stirring, the material is separated from the gaseous carbon dioxide, and the material is sent back to the neutralization device th...

Embodiment 2

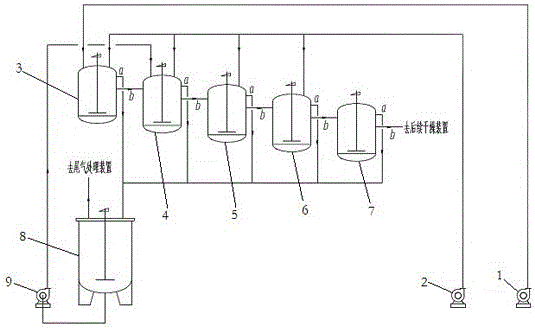

[0037] The neutralization device in this embodiment 2 adopts four-stage continuous neutralization, and the soda ash slurry is continuously added to the neutralization kettle 3, the neutralization kettle 4, and the neutralization kettle 5 according to the required amount of 22%, 28%, 28%, and 22% respectively. In the neutralization kettle 6, each stage of the neutralization reactor is provided with a foam overflow pipe 2a and a reaction material discharge overflow pipe 1b, and the position of the overflow pipe 2a is higher than that of the overflow pipe 1b.

[0038] Such as figure 1 As shown, the condensation liquid of naphthalene-based water reducer or its homologous dispersant is continuously pumped into neutralization tank 3, and the sodium carbonate slurry is continuously pumped into neutralization tank 3, neutralization tank 4, neutralization tank 5 and neutralization tank In 6, the pump-in volume in each neutralization kettle is respectively 22%, 28%, 28% and 22% of the t...

Embodiment 3

[0041] There is one neutralization kettle in this embodiment 3, that is, one-stage neutralization. The steps of the production method, other devices and their connection methods are the same as those in Embodiment 2. 30% soda ash solution is used for neutralization, and the overflow liquid flows to the foam Receiving kettle, feed liquid returns in the neutralization kettle 3 after defoaming. Others will not be described here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com