Stamping part robot welding work station

A robot welding and workstation technology, applied in welding equipment, welding accessories, manufacturing tools, etc., can solve the problems of complex shapes, small number of workpiece welds, large batches, etc., to improve the utilization rate and production efficiency, and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

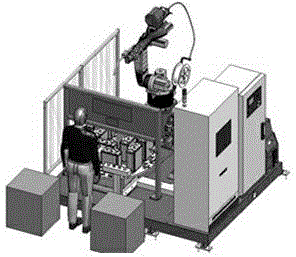

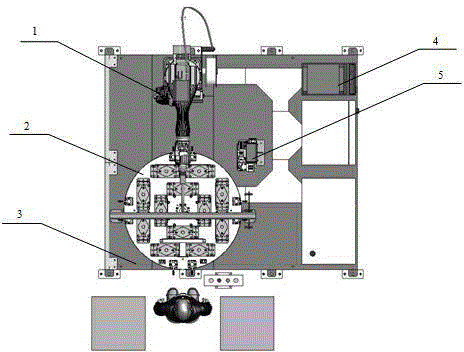

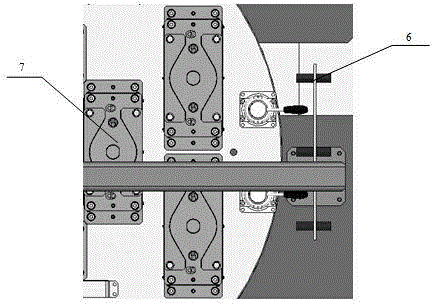

[0023] Such as figure 1 , 2 , 3, this system is mainly composed of KUKA robot, gun cleaning station, welding system, level shifter, welding station, electrical control system, etc., and the rotary platform, gun cleaning and wire cutting station, tooling and fixture have been improved. Among them, the rotary platform is anticlockwise unlimited rotation, 90° / station, 3 sets of fixtures / station, and 3 sets of leak detection devices. (The data in the following table is taken as an example of the processing parameters of a part):

[0024] Bearing (eccentricity 50mm) Repeatability Rotating speed Number of axes Radius of gyration 500Kg ≤10 arcmin ≤3r / min 1 axis 100mm

[0025] First of all, in the welding process, in order to ensure the stability of the welding torch and welding quality, the torch cleaning action is relatively frequent, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com