Method for purifying and preparing nuclear pure thorium tetrafluoride from thorium oxalate

A technology for nuclear pure thorium tetrafluoride and oxalic acid, which is applied in the field of nuclear fuel raw material preparation, can solve the problems of difficulty in meeting the purity requirements of nuclear energy fuel, low purity of thorium compounds, etc., and achieves easy expansion of production capacity, satisfactory purification effect, and good purification effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

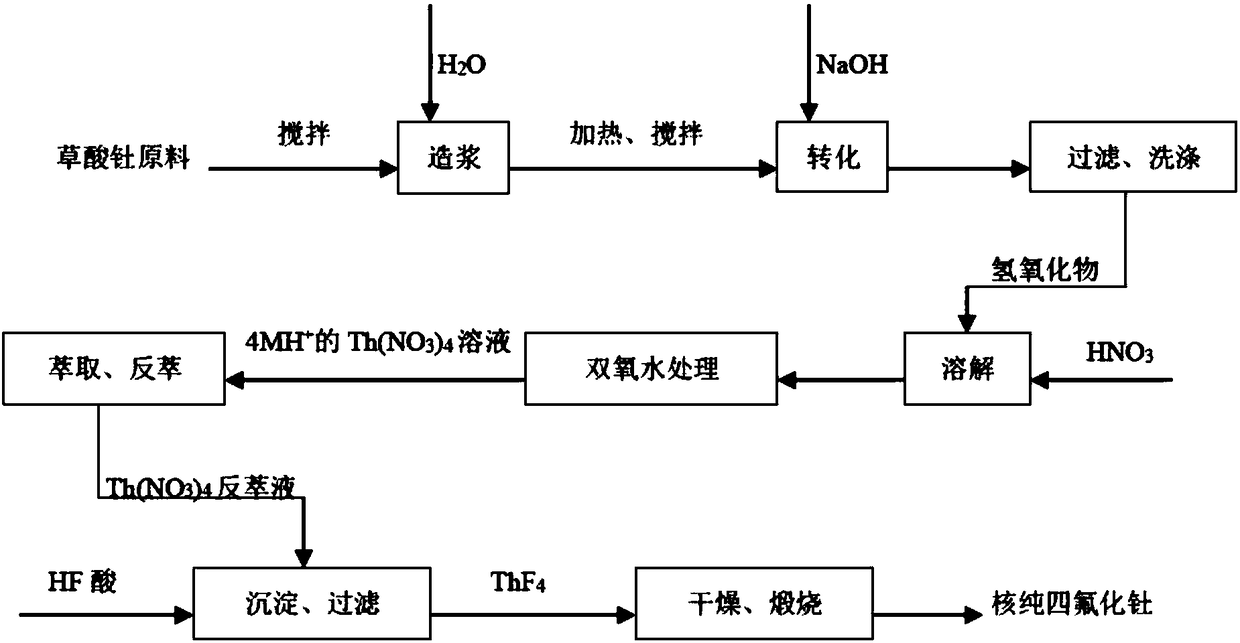

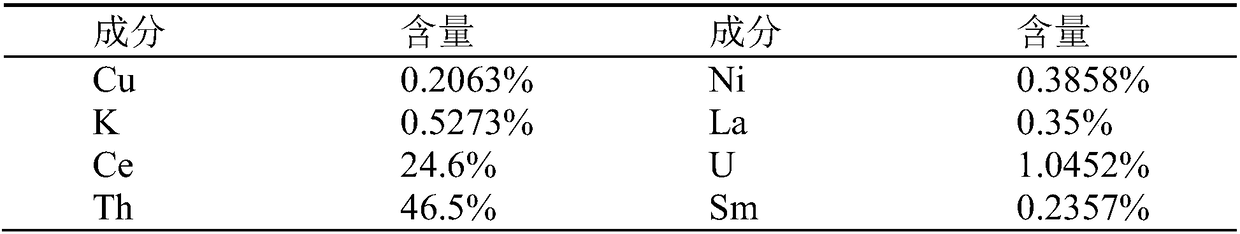

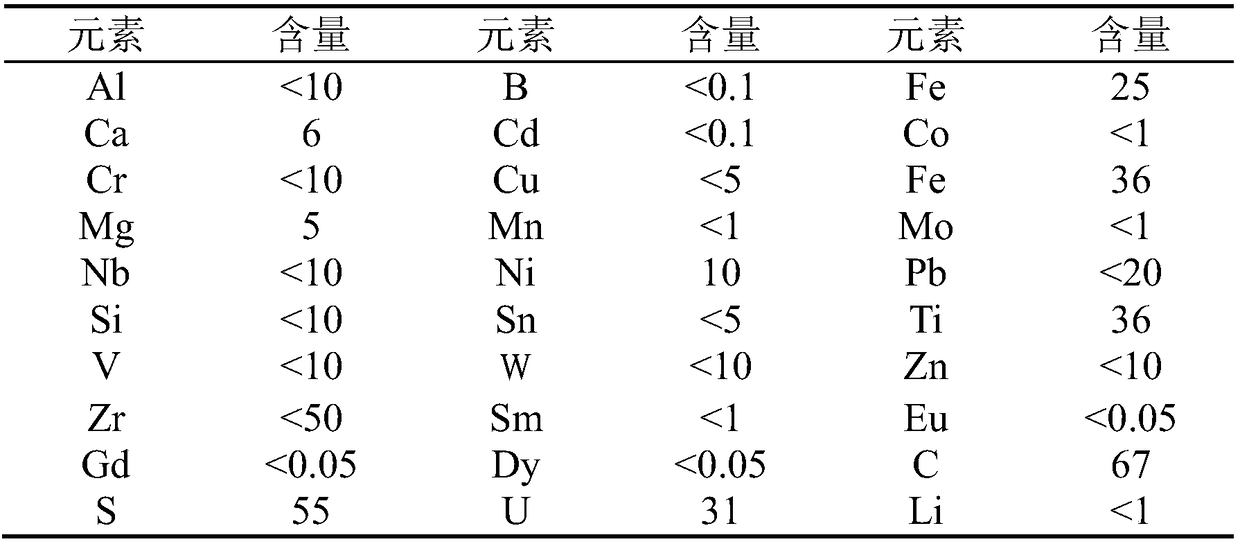

[0026] A method for purifying and preparing nuclear pure thorium tetrafluoride from thorium oxalate according to the present invention comprises the following steps:

[0027] (1) Nitric acid dissolved after thorium oxalate alkali conversion

[0028] Weigh the thorium oxalate raw material and add water to make a slurry, add sodium hydroxide, the molar ratio of the thorium oxalate raw material to sodium hydroxide is 1:8, the temperature is 80°C, the holding time is 2 hours, the slurry is filtered to obtain the thorium hydroxide solid, and then Add nitric acid to the filtered solid for dissolution, the amount of nitric acid added is controlled at 4mol / L in the solution obtained after the dissolution reaction; then filter to obtain a thorium nitrate solution, and the concentration of thorium nitrate in the solution is 80g / L;

[0029] (2) Hydrogen peroxide reduces tetravalent cerium, low-concentration TBP extracts uranium and high-concentration TBP extracts thorium:

[0030] In st...

Embodiment 2

[0040] A method for purifying and preparing nuclear pure thorium tetrafluoride from thorium oxalate according to the present invention comprises the following steps:

[0041] (1) Nitric acid dissolved after thorium oxalate alkali conversion

[0042] Weigh the thorium oxalate raw material and add water to make a slurry, add sodium hydroxide, the molar ratio of the thorium oxalate raw material to sodium hydroxide is 1:4, the temperature is 60°C, the holding time is 5 hours, the slurry is filtered to obtain thorium hydroxide solid, and then Add nitric acid to the filtered solid to dissolve, and the amount of nitric acid added is controlled at 0.5mol / L in the solution obtained after the dissolution reaction; then filter to obtain a thorium nitrate solution, and the concentration of thorium nitrate in the solution is 90g / L;

[0043](2) Hydrogen peroxide reduces tetravalent cerium, low-concentration TBP extracts uranium and high-concentration TBP extracts thorium:

[0044] In step ...

Embodiment 3

[0051] A method for purifying and preparing nuclear pure thorium tetrafluoride from thorium oxalate according to the present invention comprises the following steps:

[0052] (1) Nitric acid dissolved after thorium oxalate alkali conversion

[0053] Weigh the thorium oxalate raw material and add water to make a slurry, add sodium hydroxide, the molar ratio of the thorium oxalate raw material to sodium hydroxide is 1:12, the temperature is 110°C, the holding time is 5 hours, the slurry is filtered to obtain thorium hydroxide solid, and then Add nitric acid to the filtered solid for dissolution, and the amount of nitric acid added is controlled at 5mol / L in the dissolved solution obtained after the dissolution reaction; then filter to obtain a thorium nitrate solution, and the concentration of thorium nitrate in the solution is 150g / L;

[0054] (2) Hydrogen peroxide reduces tetravalent cerium, low-concentration TBP extracts uranium and high-concentration TBP extracts thorium:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com