Chalk Preparation Raw Meal System

A technology for raw meal and chalk, which is applied in the field of chalk preparation system for cement raw meal, can solve the problems that the ball mill cannot meet the requirements of drying, waste grinding energy, and is difficult to run stably, so as to improve the drying and dispersing efficiency, improve the The effect of flue gas temperature and elimination of material circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

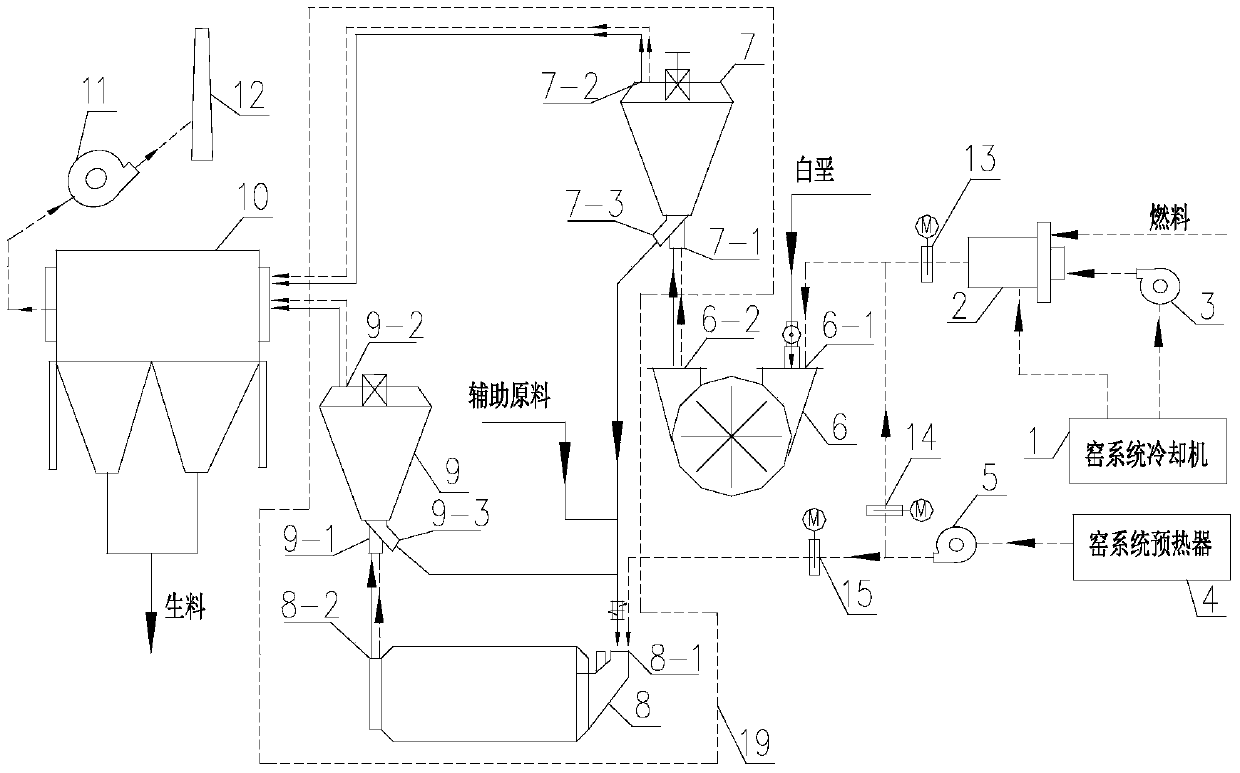

[0029] As the first embodiment of the present invention, such as figure 1 , the grinding powder separator 19 is composed of the first powder separator 7, the grinding device 8 and the second powder separator 9; the outlet 6-2 of the drying crusher and the inlet 7 of the first powder separator -1 is connected; the second hot air discharged from the air outlet of the second induced draft fan 5 is connected with the inlet 8-1 of the grinding device; the outlet 8-2 of the grinding device is connected with the inlet 9-1 of the second powder separator The fine powder outlet 7-2 of the first powder separator is connected with the dust collector 10 after being connected in parallel with the fine powder outlet 9-2 of the second powder separator; the coarse powder outlet 7-3 of the first powder separator is connected with the second The coarse powder outlet 9-3 of the classifier is connected in parallel with the inlet 8-1 of the grinding device.

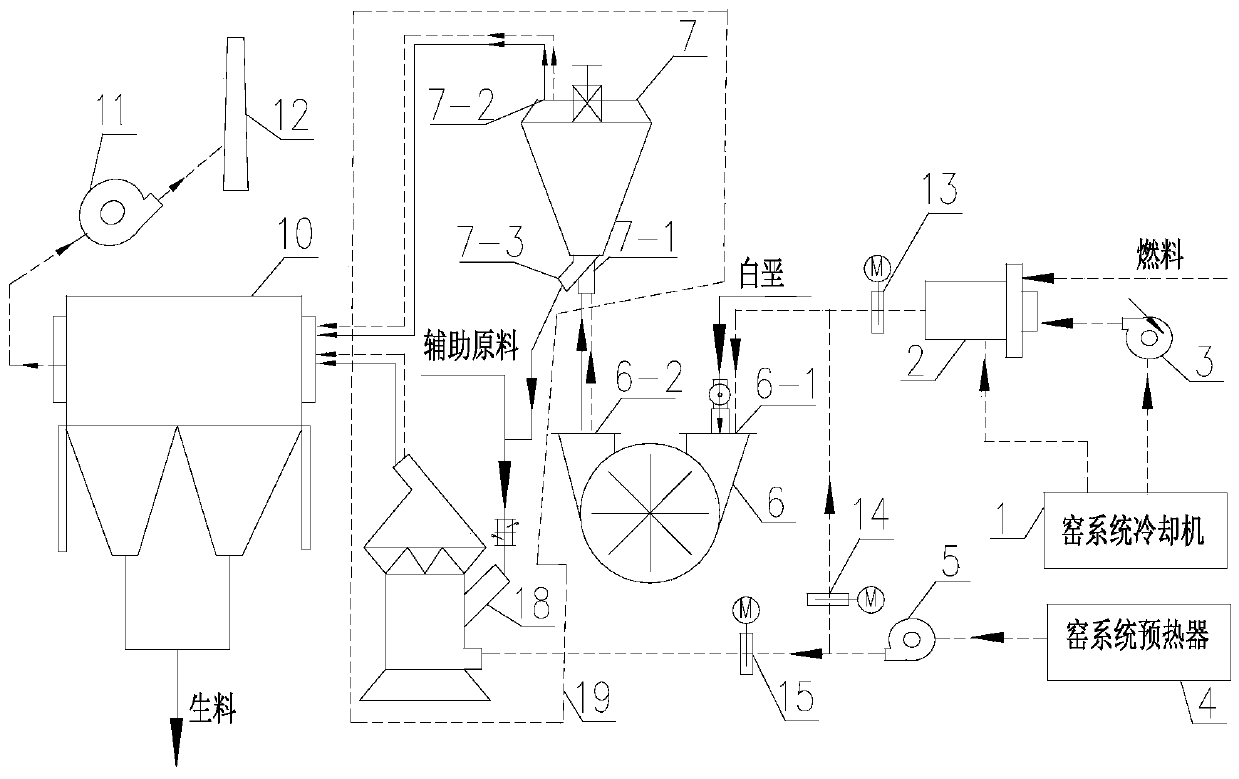

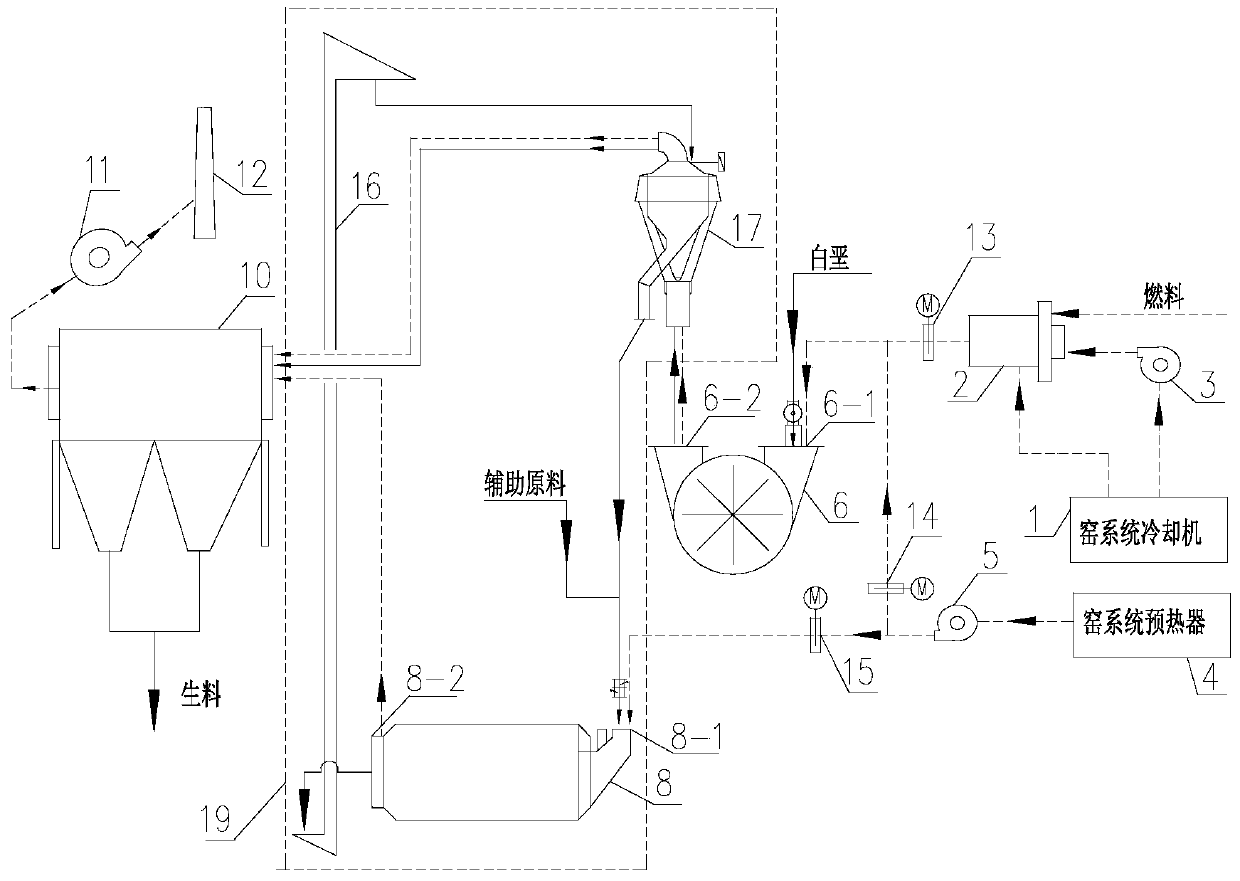

[0030] As a second embodiment of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com