Gradient material for castable and preparation method thereof

A gradient material and castable technology, applied in the field of refractory materials, can solve the problems of high temperature reaction expansion, easy hydration cracking, etc., and achieve the effects of stable properties, reduced weight, and low bulk density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A preparation method for a gradient material for castables, comprising the following steps:

[0035] (1) Al 2 o 3 Powder dispersed in water to prepare Al 2 o 3 Slurry, Al 2 o 3 Al in slurry 2 o 3 The mass fraction of powder is 30%, Al 2 o 3 60% mass fraction of the powder can pass through a 325-mesh sieve.

[0036] (2) Coating Al on the surface of magnesia particles by hanging slurry 2 o 3 slurry, that is, magnesia particles are immersed in Al 2 o 3 In the slurry, take it out after staying for a while, and coat a layer of Al on the surface of the magnesia particles 2 o 3 Slurry, Al 2 o 3 The thickness of the slurry layer is about 1mm.

[0037] (3) will be wrapped with Al 2 o 3 The magnesia particles in the slurry layer were placed in a sagger tunnel kiln and fired at 1750°C for 3 hours to obtain a gradient material.

[0038] Performance Characterization

[0039] Chemical Composition Testing

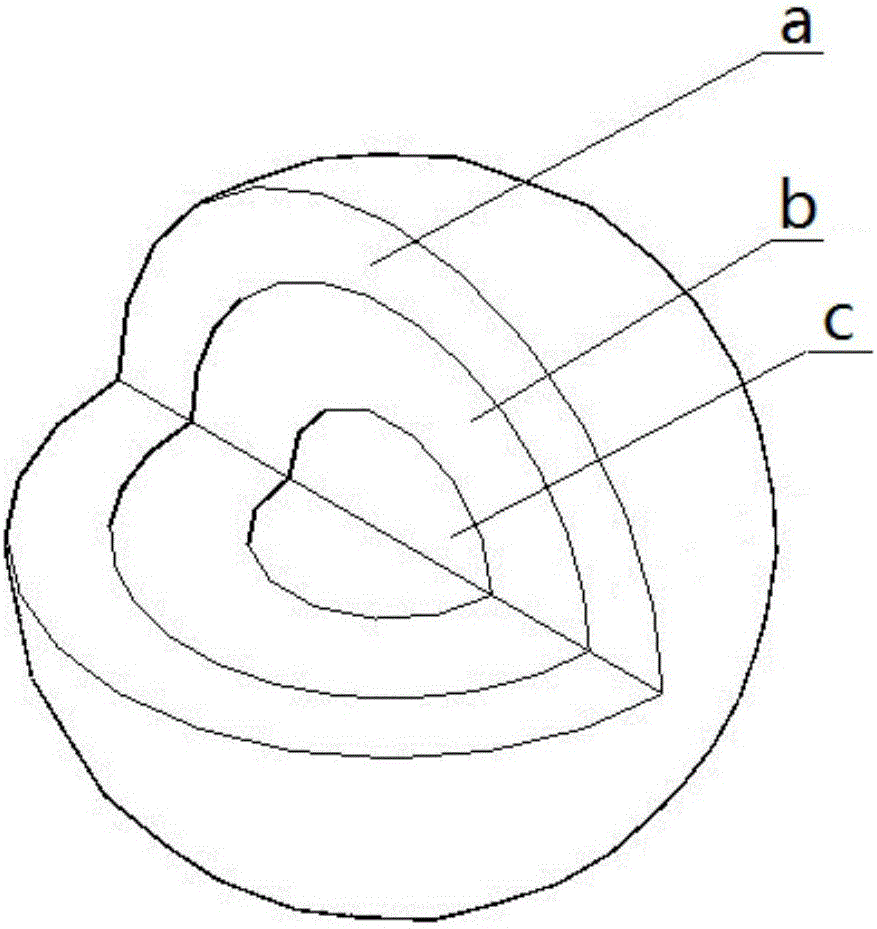

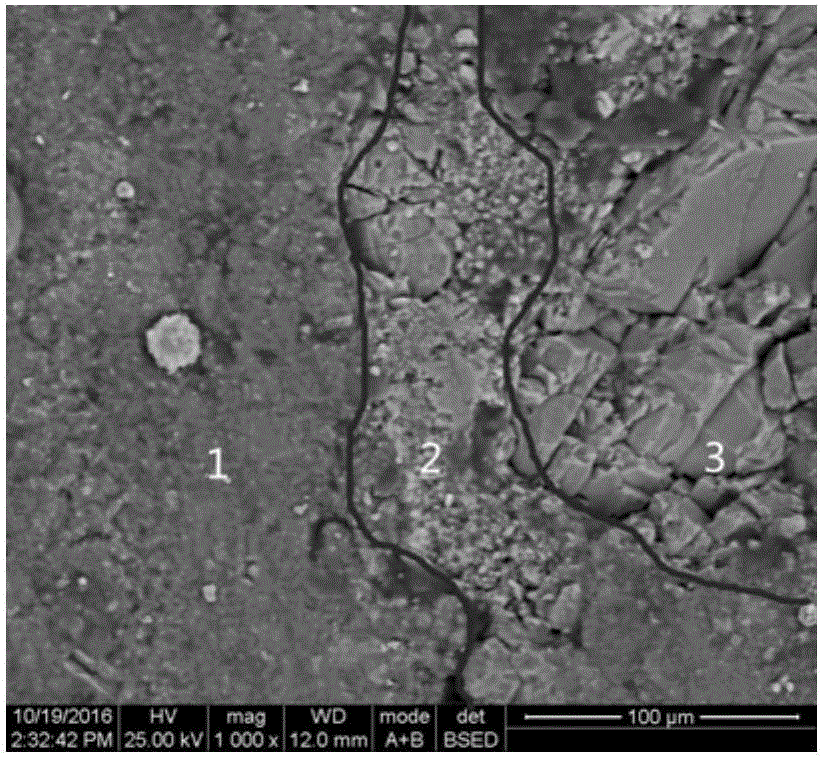

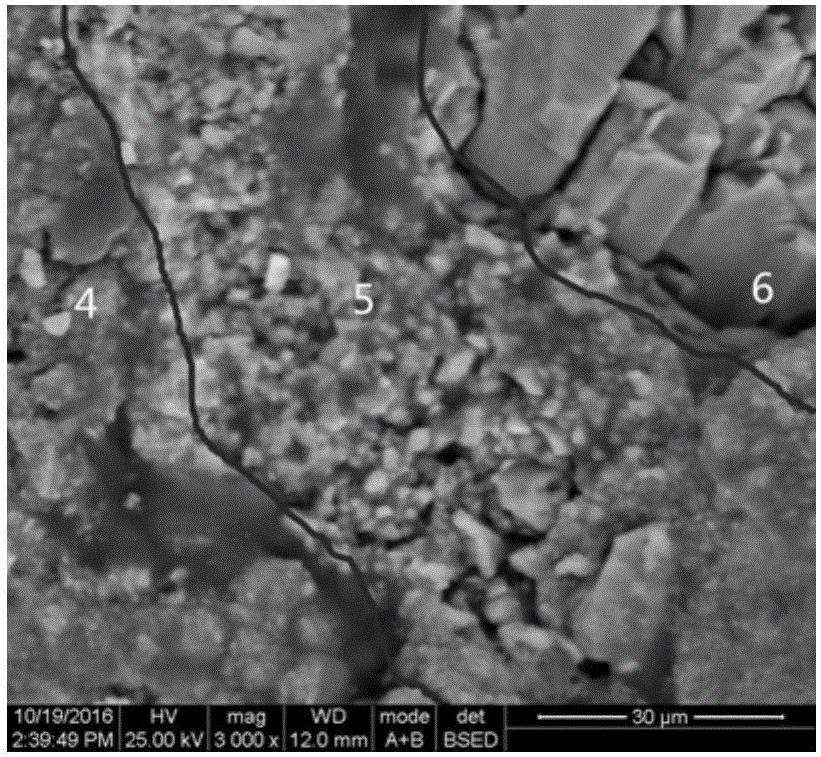

[0040] The core, transition layer and shell layer of the...

Embodiment 2~8

[0076] The experimental parameters of each embodiment are shown in Table 8. Unless otherwise specified, the experimental conditions are the same as in Example 1.

[0077] Table 8

[0078]

Embodiment 2

[0079] In embodiment 2, the surface of the magnesia particles is activated. The treatment method is: use a mixer with sharp parts inside to stir and shave the magnesia particles to make a fresh surface and optimize the reactivity of the magnesia particle surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com