Method and device for separating impurities in sec-butyl acetate with methanol serving as azeotrope agent by adopting solvent recycling system

A sec-butyl acetate recovery system technology, applied in the field of separation of impurities in sec-butyl acetate, can solve the problems of high energy consumption for separation and low purity of sec-butyl acetate, and achieve high purity and increased profit margins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

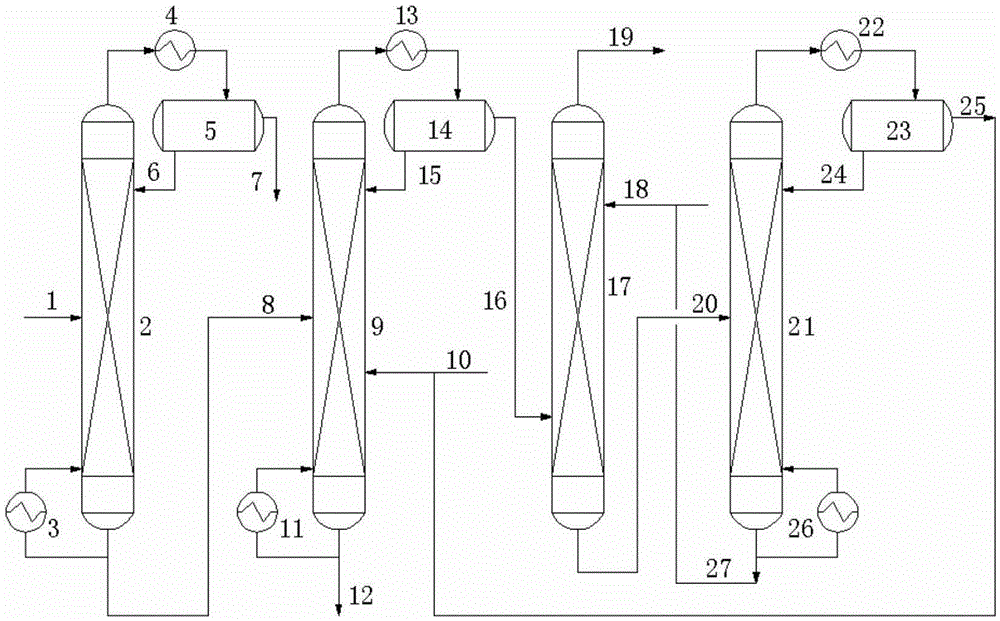

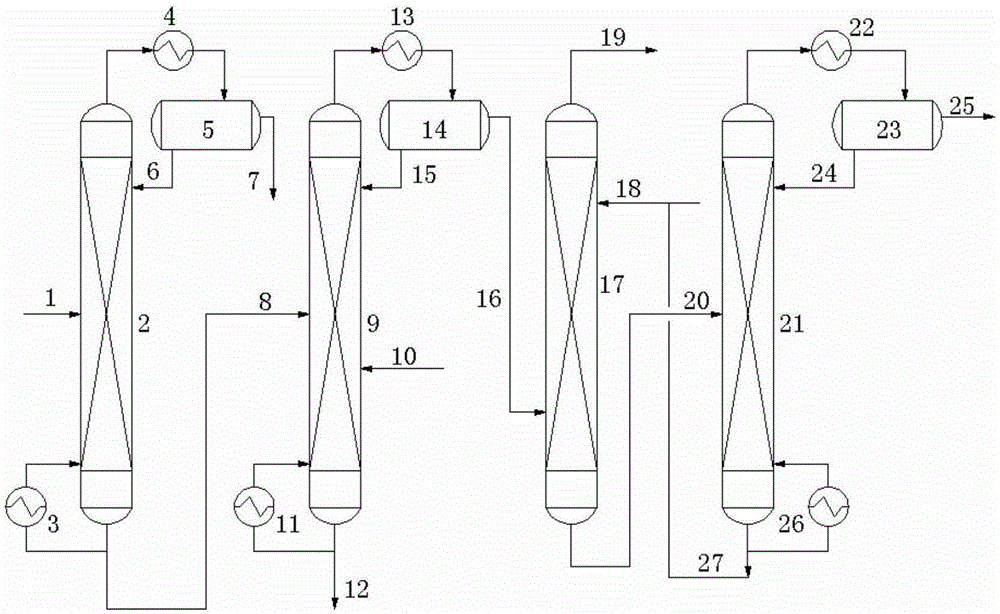

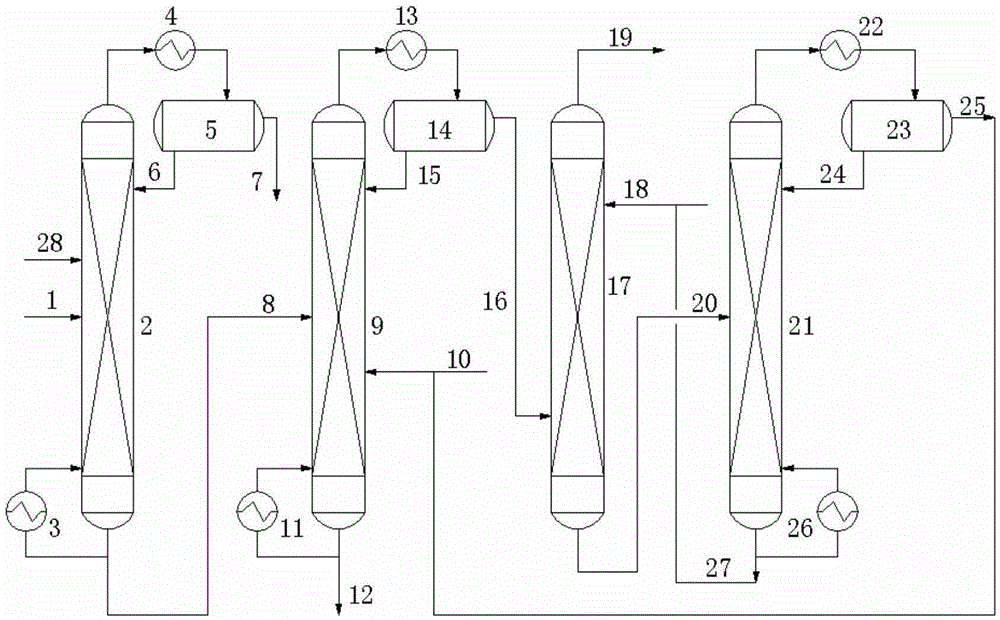

[0064] Such as figure 1As shown, the sec-butyl acetate 1 containing impurity is sent into the first azeotropic distillation tower 2 with the speed of 10t / h, wherein, the composition of this mixed material is: water 0.20%, sec-butanol 0.01%, sec-acetic acid Butyl ester 99.29%, C8 olefin 0.50%, water, sec-butanol, part of sec-butyl acetate and C8 olefin are steamed to the top of the tower, after being condensed by condenser 4, stratification is carried out in reflux tank 5, and the water phase is separated by 0.02t / The speed of h is discharged, and the oil phase is refluxed. Wherein, the operating conditions of the first azeotropic distillation column 2 are: the top pressure is normal pressure, the top temperature is 87 ° C, and the reflux ratio is 4.5. The first azeotropic distillation column The mixed material 8 containing sec-butyl acetate and C8 olefins in the bottom of the distillation tower is sent to the second azeotropic rectification tower 9 at a speed of 9.98t / h, and...

Embodiment 2

[0067] Such as Figure 4 As shown, the sec-butyl acetate 1 containing impurities is sent into the second azeotropic distillation column 9 at a speed of 10t / h, wherein the composition of the mixed material is: 40.20% sec-butyl acetate, 59.80% C8 olefins, And add entrainer methyl alcohol 10, the feed inlet of methyl alcohol is arranged at the 10th tray place below the sec-butyl acetate mixture feed inlet, wherein, the mass ratio of the amount of methyl alcohol added and the amount of C8 olefins is 1: 1. The operating conditions of the second azeotropic distillation column 9 are: the pressure at the top of the column is normal pressure, the temperature at the top of the column is 63°C, the reflux ratio is 10, and sec-butyl acetate falls into the bottom of the column as a product at a rate of 4.02t / h speed extraction, C8 olefins and methanol form an azeotrope and evaporate from the top of the tower. After condensation, part of it is refluxed, and part is sent to the washing tower ...

Embodiment 3

[0070] Such as figure 1 As shown, the sec-butyl acetate 1 containing impurities is sent into the first azeotropic rectification column 2 at a speed of 10t / h, wherein the composition of the mixed material is: water 5.00%, sec-butyl acetate 44.55%, C8 50.45% olefins, water, part of sec-butyl acetate and C8 olefins are steamed to the top of the tower, after being condensed by the condenser 4, stratification is carried out in the reflux tank 5, the water phase is discharged at a speed of 0.5t / h, and the oil phase is refluxed, Wherein, the operating conditions of the first azeotropic rectification tower 2 are: the tower top pressure is normal pressure, and the tower top temperature is 76 ℃, and the reflux ratio is 5.7, and the first azeotropic rectification tower bottom contains sec-butyl acetate, The mixed material of C8 olefins is sent into the second azeotropic rectification column 9 with the speed of 9.5t / h, and add entrainer methyl alcohol 10, the feed inlet of methyl alcohol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com