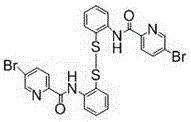

Preparation method of rubber peptizer 2,2'-di(5-bromo-pyridine-2-formamido) diphenyl disulfide

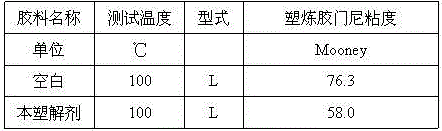

A technology of diaminodiphenyl disulfide and rubber peptizer, applied in the direction of organic chemistry and the like, can solve the problems such as synthesis and performance of dipyridine substituted diphenyl disulfide compounds that have not been reported in literature, and achieves lowering temperature, improving The effect of rubber viscosity and fluidity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

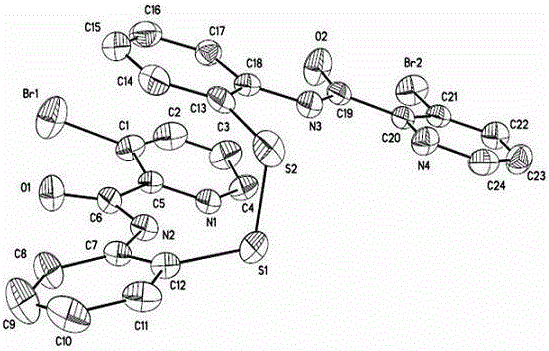

[0023] Add 1.0mmol 2,2'-diaminodiphenyl disulfide and 10mL methanol to the reaction flask, stir on a magnetic stirrer, add 0.1mmol dicyclohexylcarbodiimide, dropwise add 2.0mmol 5-bromo-pyridine- The methanol solution of 2-formic acid immediately produced a yellow precipitate, reacted for 10 hours, filtered with suction, dried, and the yield was 72%. Melting point: 192-194°C

Embodiment 2

[0025] Add 1.0mmol 2,2'-diaminodiphenyl disulfide and 10mL methanol to the reaction flask, stir on a magnetic stirrer, add 0.2mmol dicyclohexylcarbodiimide, dropwise add 2.0mmol 5-bromo-pyridine- The methanol solution of 2-formic acid immediately produced a yellow precipitate, reacted for 10 hours, filtered with suction, dried, and the yield was 76%. Melting point: 192-194°C

Embodiment 3

[0027] Add 1.0mmol 2,2'-diaminodiphenyl disulfide and 10mL methanol to the reaction flask, stir on a magnetic stirrer, add 0.2mmol dicyclohexylcarbodiimide, dropwise add 2.1mmol 5-bromo-pyridine- The methanol solution of 2-formic acid immediately produced a yellow precipitate, reacted for 10 hours, filtered with suction, dried, and the yield was 79%. Melting point: 192-194°C

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com