A kind of production device and method of polyether modified silicone

A technology of polyether modification and production method, which is applied in the field of preparation of polyether modified silicone, which can solve problems such as damage to health, pollution of the environment, and low production capacity, so as to improve reactivity, reduce potential safety hazards, and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

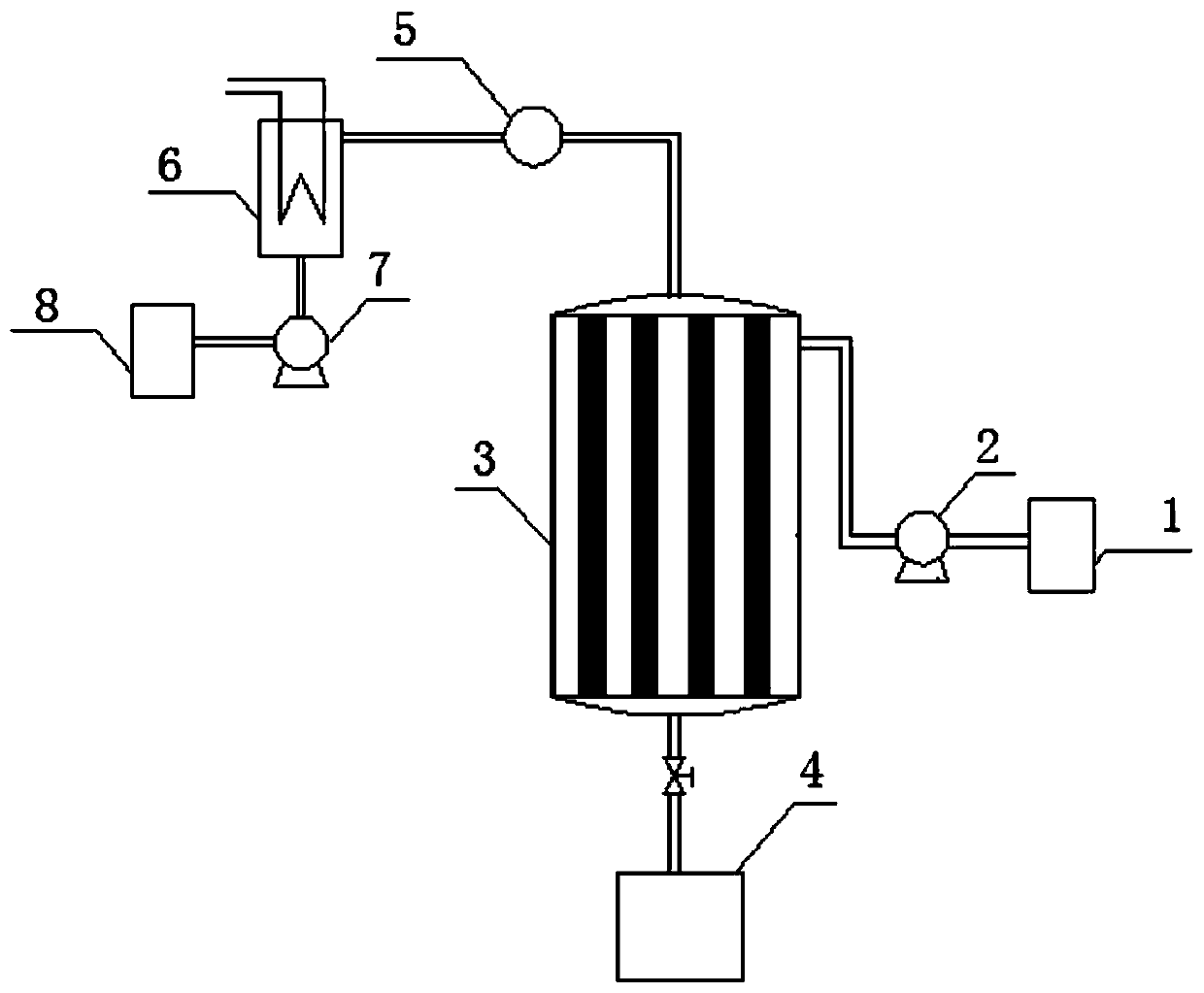

Method used

Image

Examples

Embodiment 1

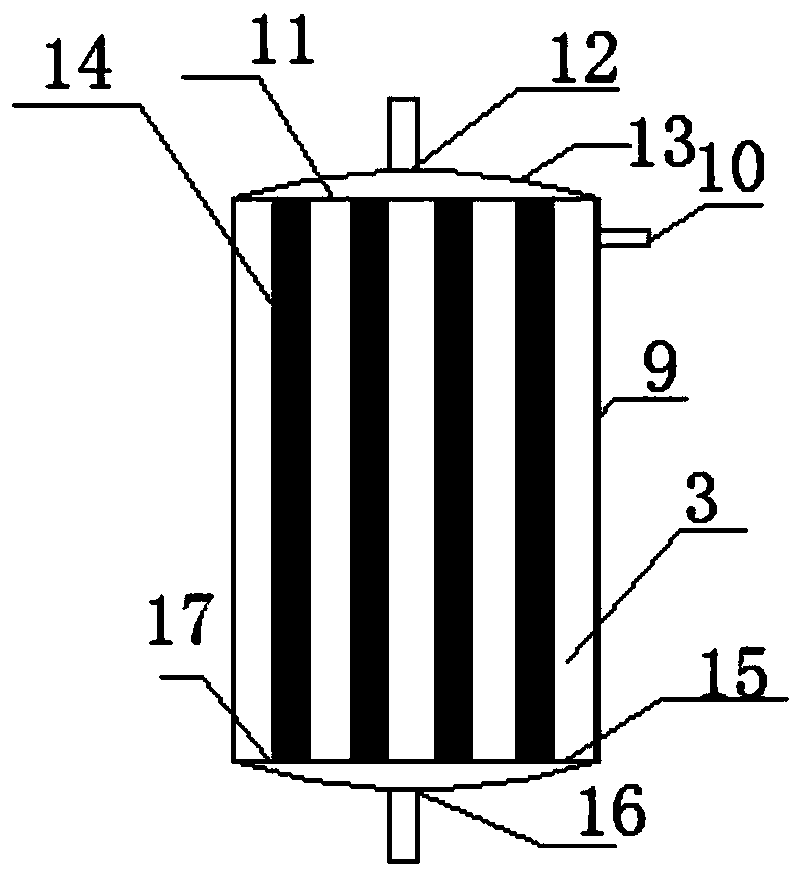

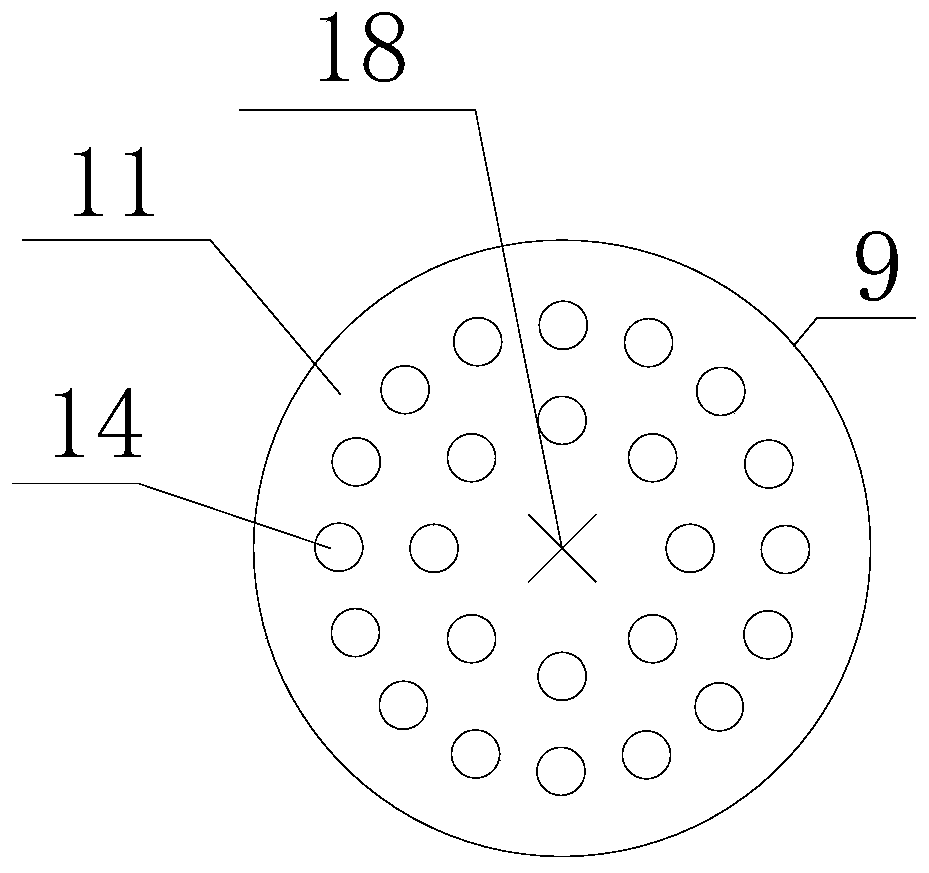

[0036] In this embodiment, the ceramic membrane tube 14 used is alumina, the diameter of the ceramic membrane tube 14 is 20mm, the average aperture of the ceramic membrane is 50nm, the center distance of the ceramic membrane tube 14 is 1.6 times of the diameter of the membrane tube, and the ceramic membrane tube 14 is from The unsealed end is sealed with a 10cm hole downwards in the longitudinal direction, the stirring device 18 is a multistage stirring device, the distance between each section is 30cm, the catalyst consumption is 3ppm, and the polyether (M=about 850g / mol) temperature after heating is 80°C, the pressure applied by the pressurizing device 5 to the hydrogen-containing silicone oil (Si-H value: 0.904g / kg) is 0.3Mpa, and the temperature of the hydrogen-containing silicone oil is 80°C after being heated by the hydrogen-containing silicone oil heating device 6. In this embodiment , after the material stayed in the membrane dispersion reactor 3 for 0.5h, the Si-H conv...

Embodiment 2

[0038] In this embodiment, the ceramic membrane tube 14 used is zirconia, the diameter of the ceramic membrane tube 14 is 40 mm, the average aperture of the ceramic membrane is 10 μm, the center distance of the ceramic membrane tube 14 is twice the diameter of the membrane tube, and the ceramic membrane tube 14 is from Unsealed one end is sealed with 25cm holes downwards in the longitudinal direction, stirring device 18 is a multistage stirring device, the distance between each section is 55cm, and the catalyst consumption is 4.5ppm, and the polyether (M=1300g / mol) temperature after heating is 90°C, the pressure applied by the pressurizing device 5 to the hydrogen-containing silicone oil (1.54g / kg) is 2Mpa, and the temperature of the hydrogen-containing silicone oil is 90°C after being heated by the hydrogen-containing silicone oil heating device 6. In this embodiment, the material is in the membrane dispersion reactor After staying in 3 for 1 h, the Si-H conversion was 99.6%. ...

Embodiment 3

[0040] In this embodiment, the ceramic membrane tube 14 used is silicon carbide, the diameter of the ceramic membrane tube 14 is 60 mm, the average aperture of the ceramic membrane is 20 μm, the center distance of the ceramic membrane tube 14 is 2.4 times of the diameter of the membrane tube, and the ceramic membrane tube 14 is from Unsealed one end is sealed with 40cm holes downwards in the longitudinal direction, stirring device 18 is a multistage stirring device, the distance between every section is 55cm, and the catalyst consumption is 6ppm, the polyether (M=4000g / mol) temperature is 100°C, the pressure applied by the pressurizing device 5 to the hydrogen-containing silicone oil is 3Mpa, and the temperature of the hydrogen-containing silicone oil (Si-H value: 1.44g / kg) is 100°C after being heated by the hydrogen-containing silicone oil heating device 6. In the embodiment, after the material stays in the membrane dispersion reactor 3 for 1.5h, the Si-H conversion rate is ≥...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com