Continuous fiber-reinforced thermoplastic composite resin rib

A technology for reinforcing thermoplastics and thermoplastic resins, applied in the field of continuous fiber reinforced thermoplastic composite resin bars, which can solve the problems of non-recyclable FRP bar materials, obstacles to popularization and application of resin bars, environmental damage, etc., and achieve strong designability and light weight , good abrasion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

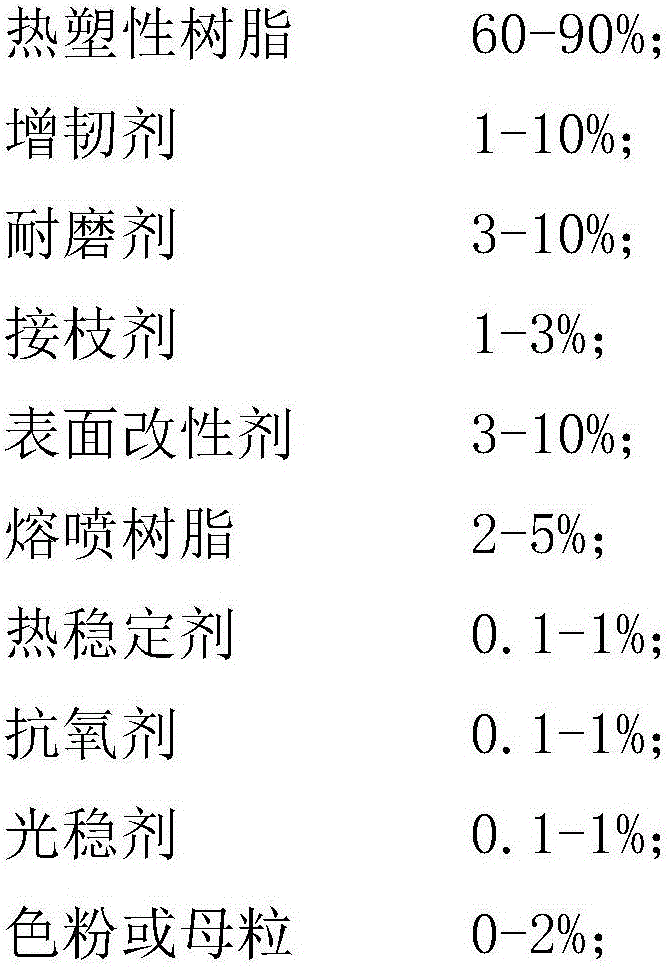

Method used

Image

Examples

Embodiment

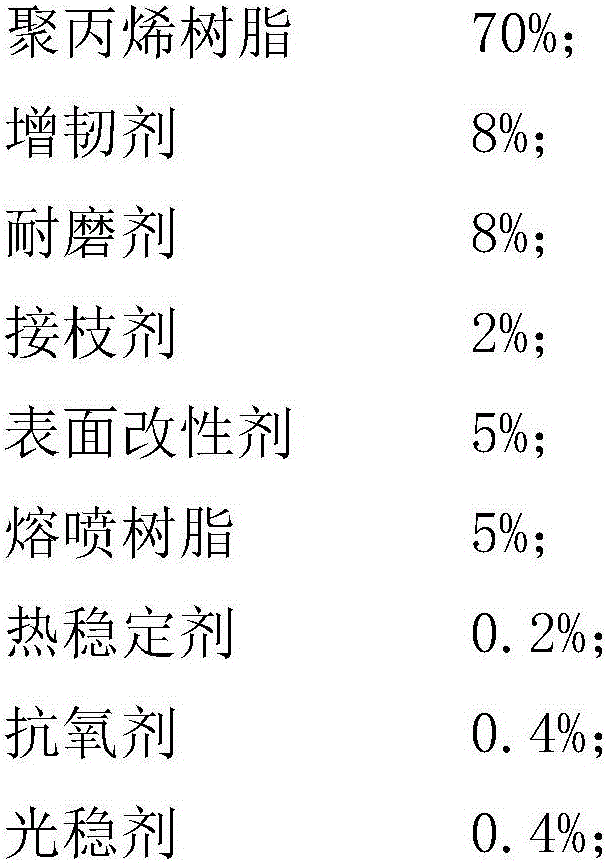

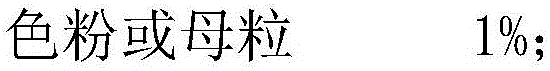

[0020] 1. Continuous glass fiber reinforced polypropylene reinforcement

[0021] (1) Accurate weighing

[0022]

[0023]

[0024] Then pour the materials together into a high-speed mixer, mix at a low speed for 5 minutes, then send the mixed materials into the extruder for extrusion, and then send the mixed materials into the twin-screw extruder for extrusion, after cooling, Dried and diced to make masterbatch.

[0025] (2) Guide the continuous glass fiber through the creel, thread the fiber, gather the fiber, spread the fiber to a certain surface density, and after a certain width, melt it in the step (1) of extruding through the extruder die. After the modified resin is coated and roll-formed, it is cut into filaments and collected into rolls.

[0026] (3) Place the prepreg tape prepared in step (2) on the unwinding reel, pull it into the mold, pass through the mold, and export it. After cutting and processing in the later stage, the finished product can be obtained....

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com