A method for resisting thermo-oxidative aging and eliminating fluorescence of c5 resin

An anti-thermal oxygen and anti-oxidant technology, applied in the field of chemistry, to achieve the effect of eliminating fluorescence and excellent protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

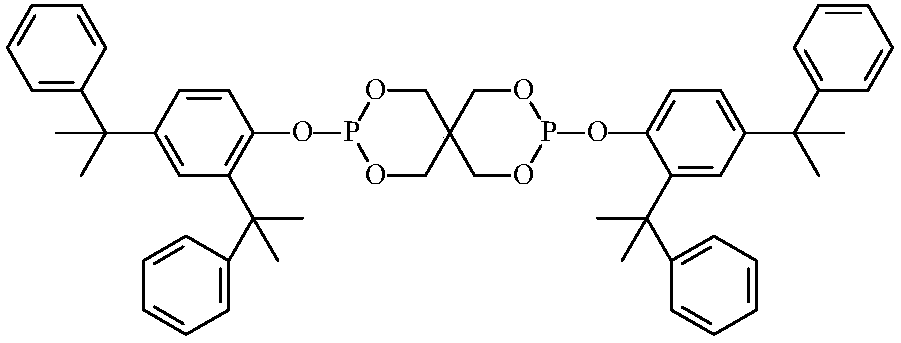

Image

Examples

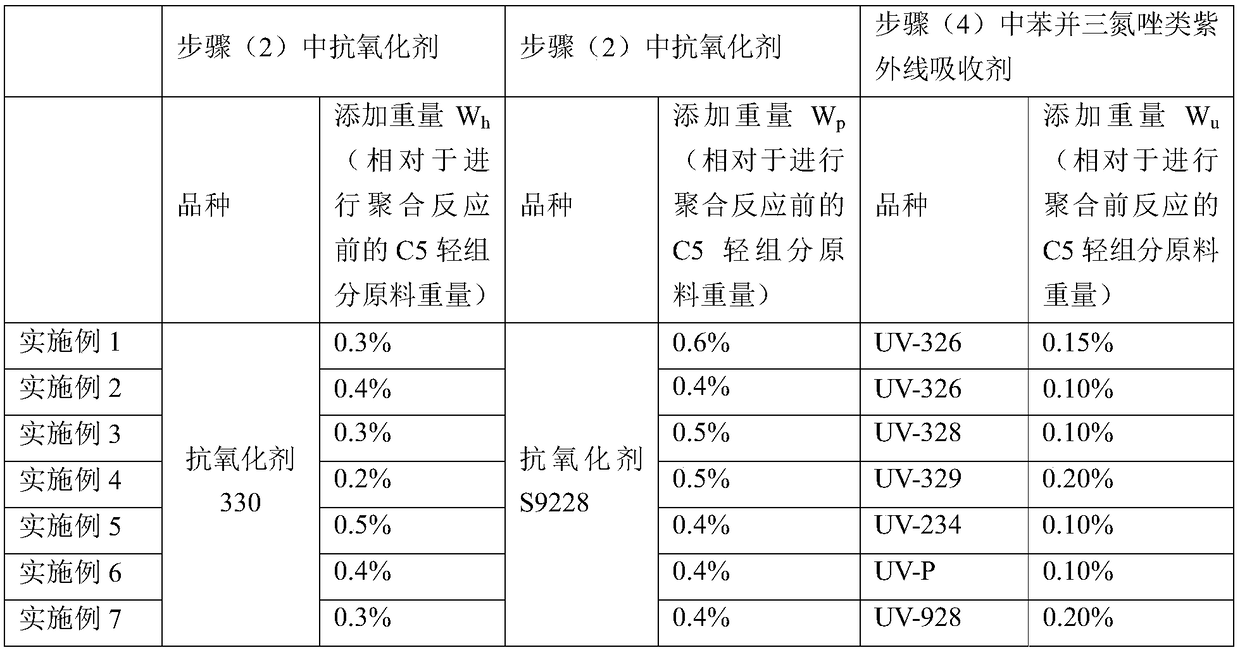

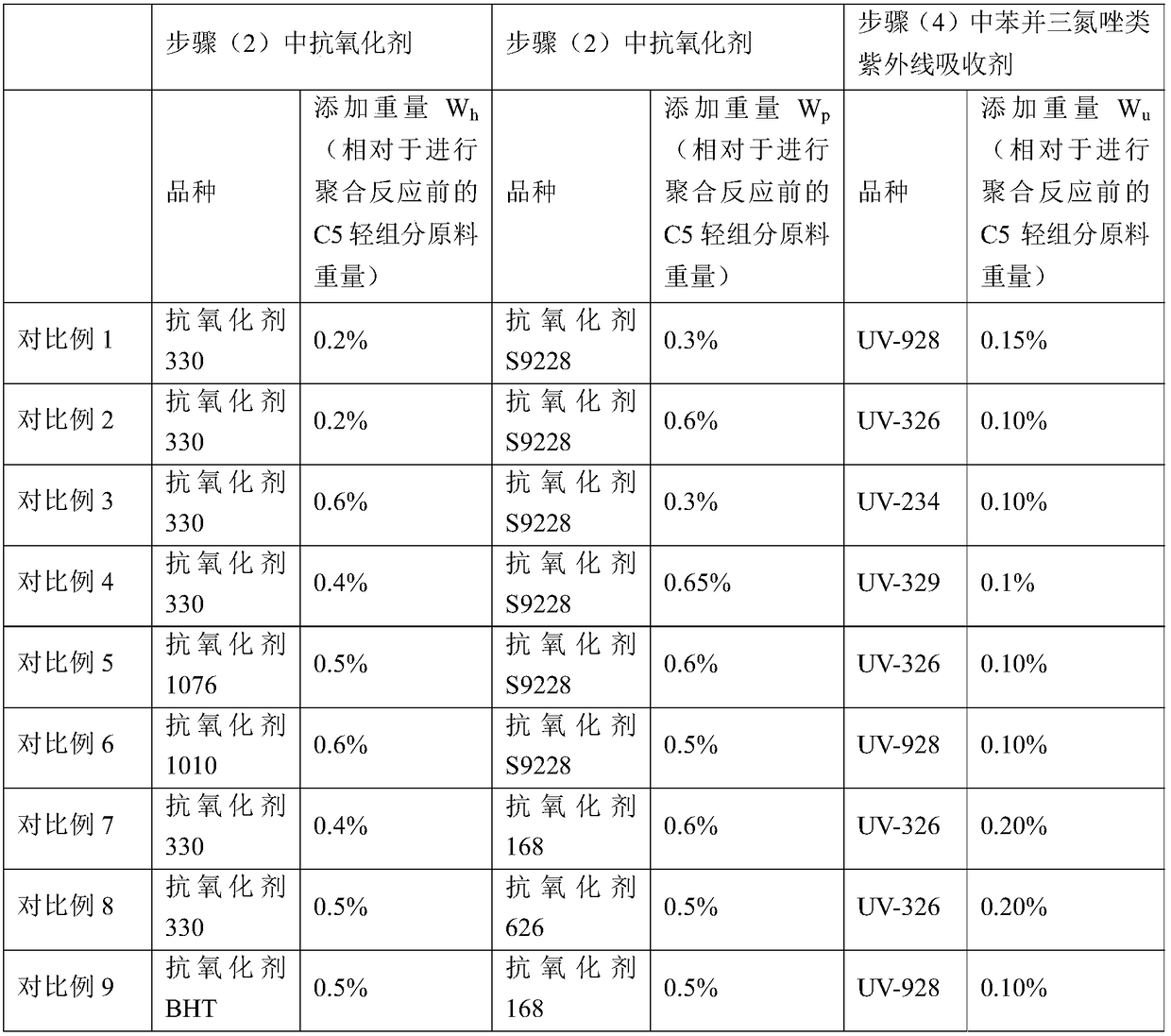

Embodiment 1-7

[0027] The preparation of C5 petroleum resin comprises the steps:

[0028] (1) First, obtain the polymerization reaction solution according to known techniques, that is, carry out rectification treatment on the C5 fraction to obtain the purified C5 fraction raw material, and then carry out rectification after thermal polymerization to obtain the C5 light component. The C5 light component before the polymerization reaction Component raw material metering, then in the catalyst AlCl 3 or BF 3 The positive ion polymerization reaction is carried out under the reaction solvent toluene, after the polymerization reaction is completed, the catalyst is washed out with alkaline water, and the waste water is separated to obtain a polymerization reaction liquid.

[0029](2) Then, using the method of the present invention, a certain weight of W is added to the polymerization reaction liquid h (relative to the C5 light component raw material weight before the polymerization reaction) the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com