Graphene-reinforced superhydrophobic finish-coat paint and preparation method thereof

A technology of graphene and water cover, applied in the field of coatings, which can solve the problems of mechanical properties of superhydrophobic coatings such as hardness, adhesion, impact resistance, poor abrasion resistance, high coating curing temperature, complex process, etc., to achieve improved hydrophobicity Performance, good weather resistance, good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

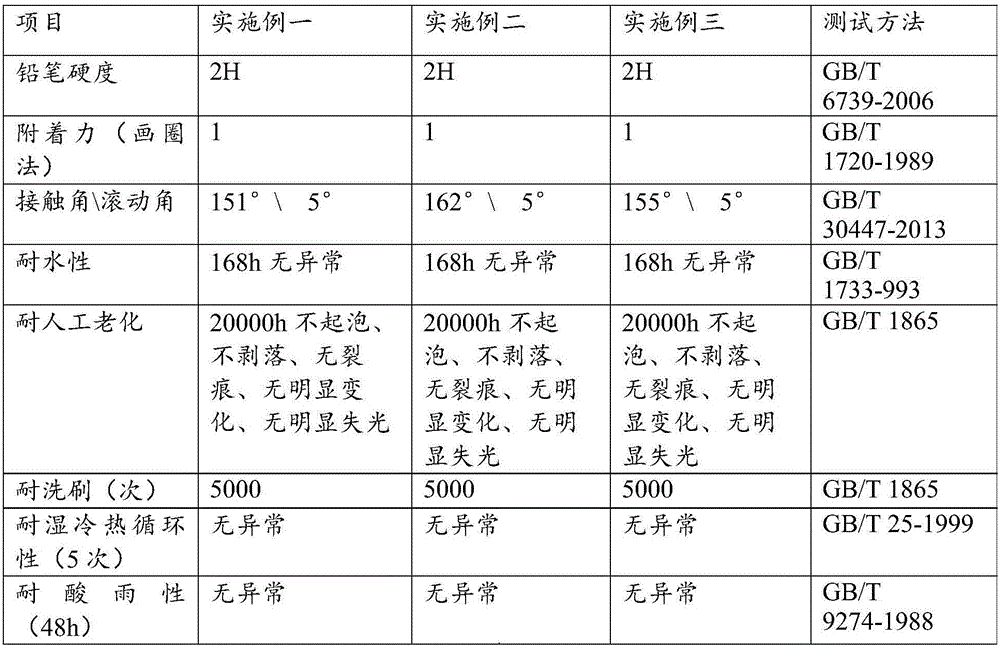

Examples

Embodiment 1

[0028] The graphene-enhanced superhydrophobic finish paint of the present invention comprises components and the percentage by weight of each component are: 40% of fluorocarbon emulsion, 10% of nano-silica sol, 0.15% of dispersant, 0.1% of defoamer, propylene glycol 0.5%, graphene oxide 0.1%, film-forming aid 0.3%, deionized water 48.85%.

[0029] Add 70 parts of silica sol to the three-necked flask, adjust the pH within the set range with hydrochloric acid, and stir evenly at a low speed; slowly add 30 parts of epoxy silane into the three-necked flask drop by drop, and heat in a water bath. After the reaction is completed, epoxy Silane-based modified silica sol, that is, nano-silica sol.

[0030] Place the graphite powder in the mixed acid, after fully stirring, repeatedly wash and dry with deionized water, remove impurities to obtain clean graphite; heat and stir the mixed solution of concentrated sulfuric acid, oxidant, and the clean graphite to obtain a dark blue mixture; ...

Embodiment 2

[0033] The graphene-enhanced superhydrophobic finish paint of the present invention comprises components and the percentage by weight of each component are: 50% of fluorocarbon emulsion, 30% of nano-silica sol, 3% of dispersant, 1% of defoamer, propylene glycol 2%, graphene oxide 0.5%, film-forming aid 2%, deionized water 11.5%.

[0034] Add 95 parts of silica sol to the three-necked flask, adjust the pH within the set range with hydrochloric acid, and stir evenly at a low speed; slowly add 5 parts of epoxy silane into the three-necked flask drop by drop, heat in a water bath, and after the reaction is completed, epoxy Silane-based modified silica sol, that is, nano-silica sol.

[0035] Place the graphite powder in the mixed acid, after fully stirring, repeatedly wash and dry with deionized water, remove impurities to obtain clean graphite; heat and stir the mixed solution of concentrated sulfuric acid, oxidant, and the clean graphite to obtain a dark blue mixture; The mixtur...

Embodiment 3

[0038] The graphene-enhanced superhydrophobic finish paint of the present invention comprises components and the percentage by weight of each component are: 45% of fluorocarbon emulsion, 20% of nano-silica sol, 1% of dispersant, 0.5% of defoamer, propylene glycol 1%, graphene oxide 0.3%, film-forming aid 1%, deionized water 31.2%.

[0039] Add 80 parts of silica sol to the three-necked flask, adjust the pH within the set range with hydrochloric acid, and stir evenly at a low speed; slowly add 20 parts of epoxy silane into the three-necked flask drop by drop, heat in a water bath, and after the reaction is completed, epoxy Silane-based modified silica sol, that is, nano-silica sol.

[0040] Place the graphite powder in the mixed acid, after fully stirring, repeatedly wash and dry with deionized water, remove impurities to obtain clean graphite; heat and stir the mixed solution of concentrated sulfuric acid, oxidant, and the clean graphite to obtain a dark blue mixture; The mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com