Biomass gasification furnace with efficient combustion

A biomass and gasifier technology, applied in the field of gasifier, can solve the problems of low thermal efficiency conversion rate, backward treatment methods, waste of resources and environment, etc., and achieve the effect of improving combustion efficiency and gas circulation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

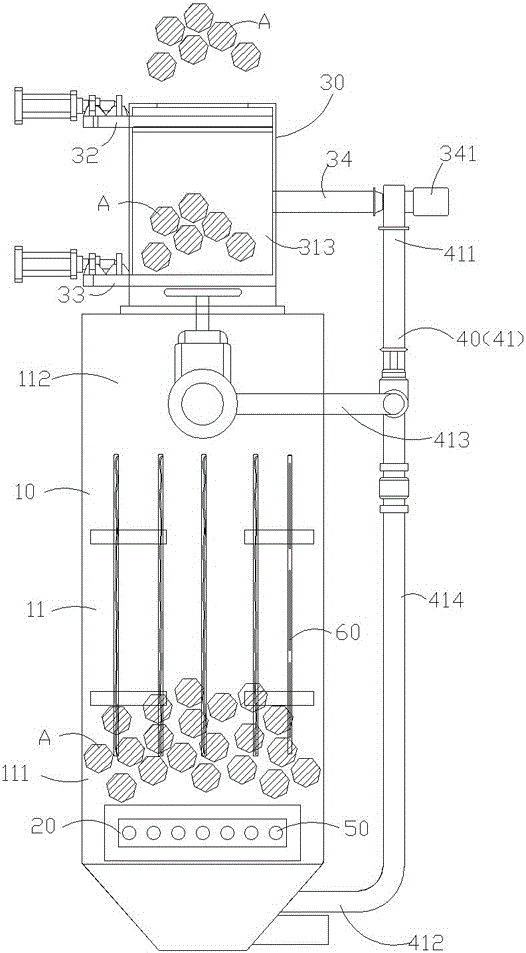

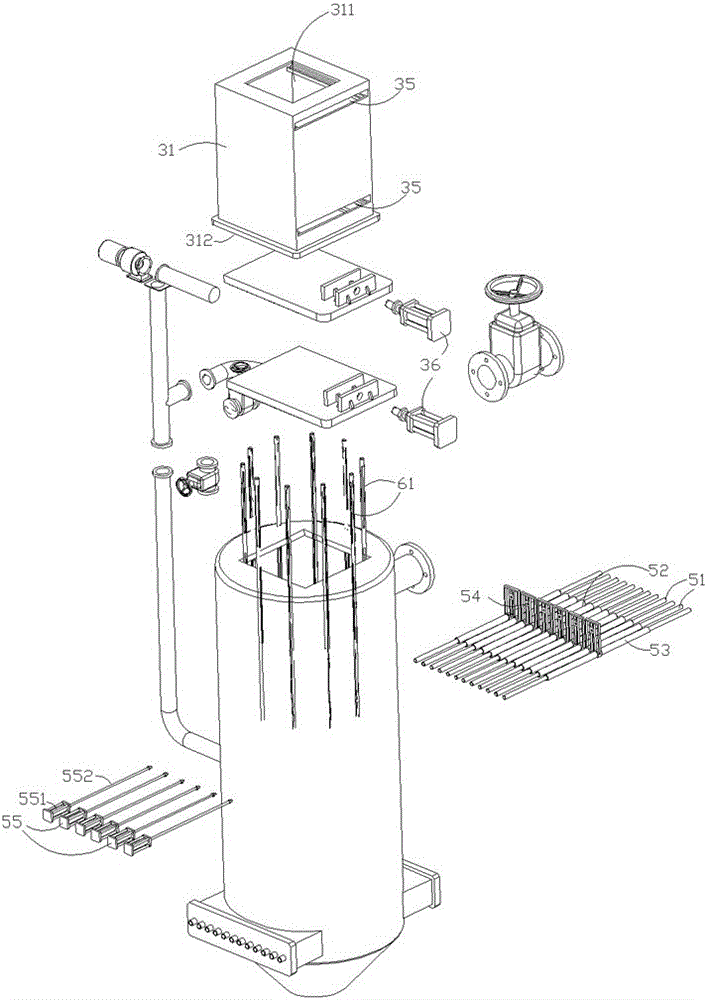

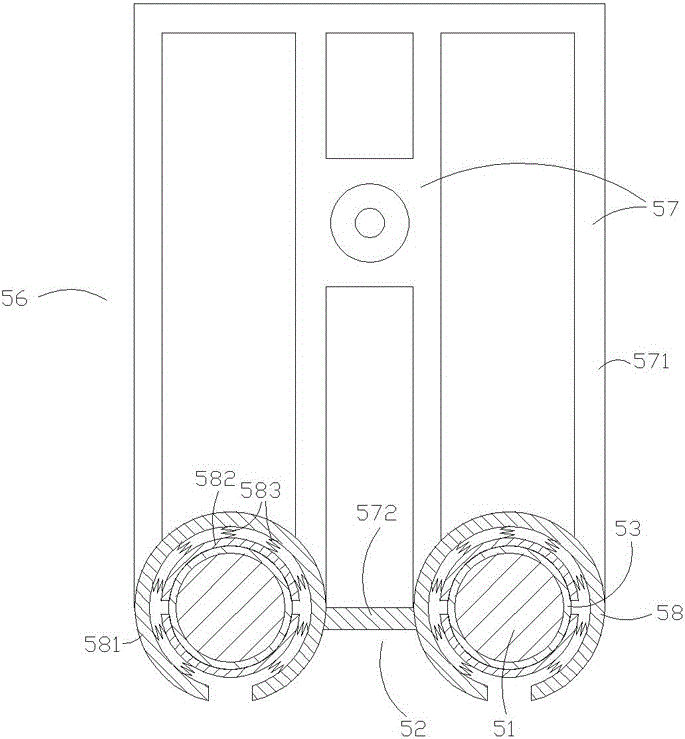

[0025] Such as Figures 1 to 4 As shown, a high-efficiency combustion biomass gasifier includes a furnace body 10 , a heating combustion system 20 , a feed system 30 and an exhaust gas circulation system 40 , wherein the furnace body 10 has a combustion chamber 11 .

[0026] The heating combustion system 20 is arranged in the combustion chamber 11 , the feeding system 30 is arranged on the top of the furnace body 10 , and the tail gas circulation system 40 is connected between the furnace body 10 and the feeding system 30 .

[0027] When the biomass gasifier 100 is working, the biomass raw material A is first put into the feed system 30, and then enters the combustion chamber 11 through the feed system 30, and the biomass raw material A is After being heated by the heating and combustion system 20 in the inner chamber 11 for oxygen-deprived combustion, the biomass raw material A is gasified into biomass gas, and finally, the biomass gas is discharged from the furnace body 10 f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com