High-chrome austenitic stainless steel

A technology of austenitic stainless steel and high-chromium austenite, applied in the field of stainless steel, can solve the problems of poor thermal stability, high cost, reduced thermal processing performance and welding performance, and achieve excellent localized corrosion resistance and excellent uniform resistance Corrosion performance, effect of good thermal heating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Example 1 Solidification structure and hot workability of high chromium austenitic stainless steel

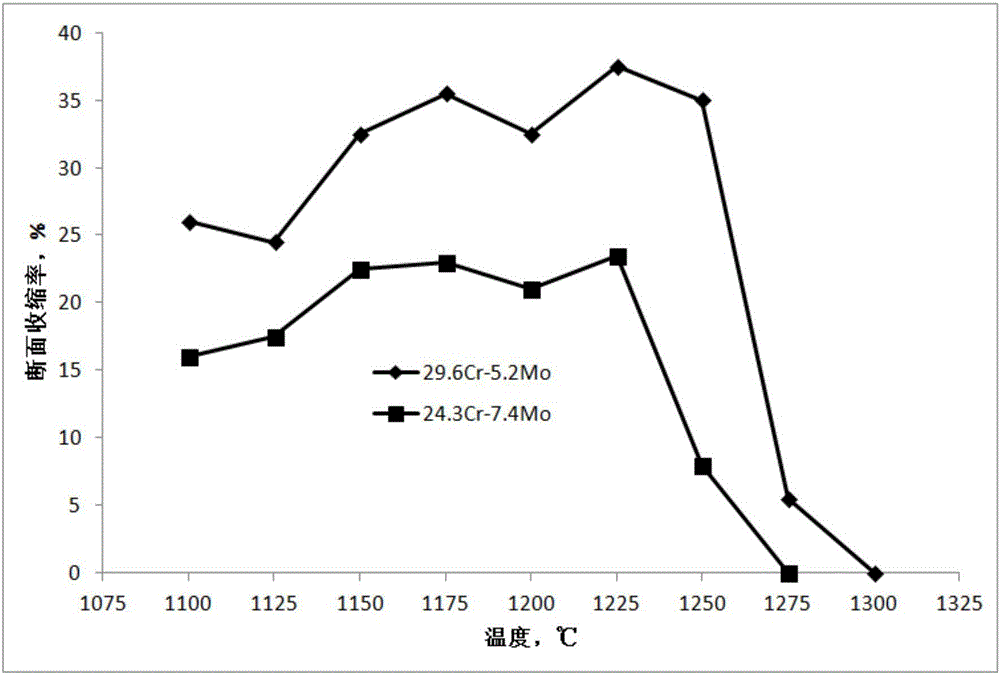

[0044] attached figure 1 The hot workability curves of 4# ingot (29.6Cr-5.2Mo) and 13# ingot (24.3Cr-7.4Mo) are shown. In the hot working temperature range of 1100~1250 ℃, the hot working performance of 4# ingot is higher than that of 13# ingot; the hot working performance of 4# ingot drops obviously at 1250 ℃, and its section shrinkage rate is 8%, which is much lower than that of 13# ingot. 35% in 4# ingot. The results show that too high Mo content and too low Cr content have adverse effects on hot workability in high temperature zone of high chromium austenitic stainless steel ingot.

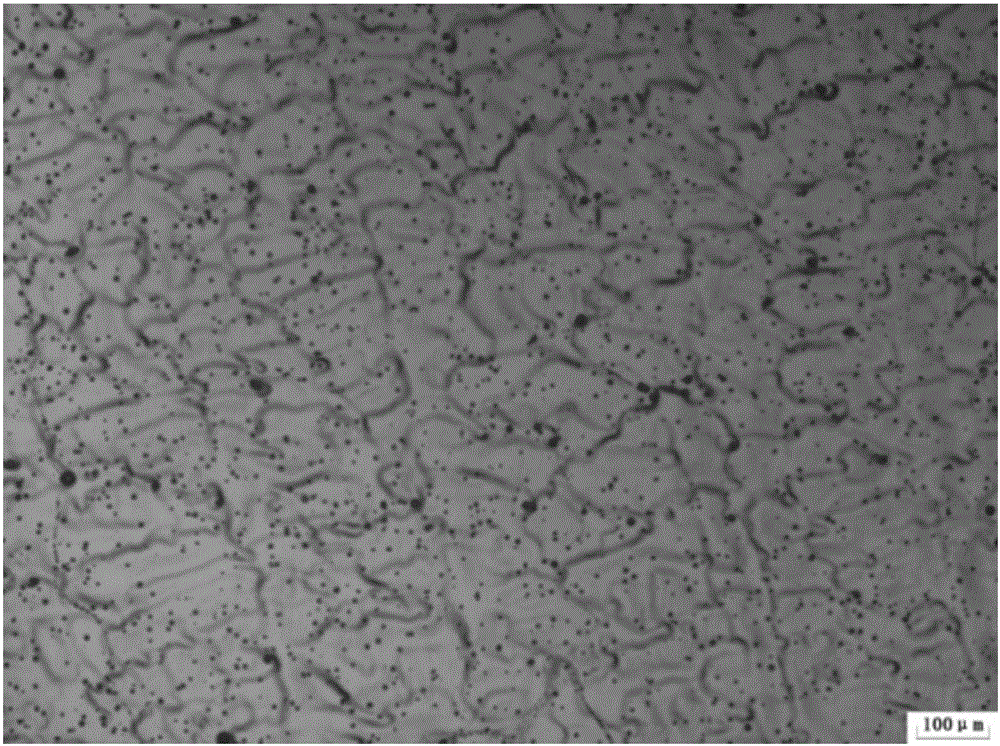

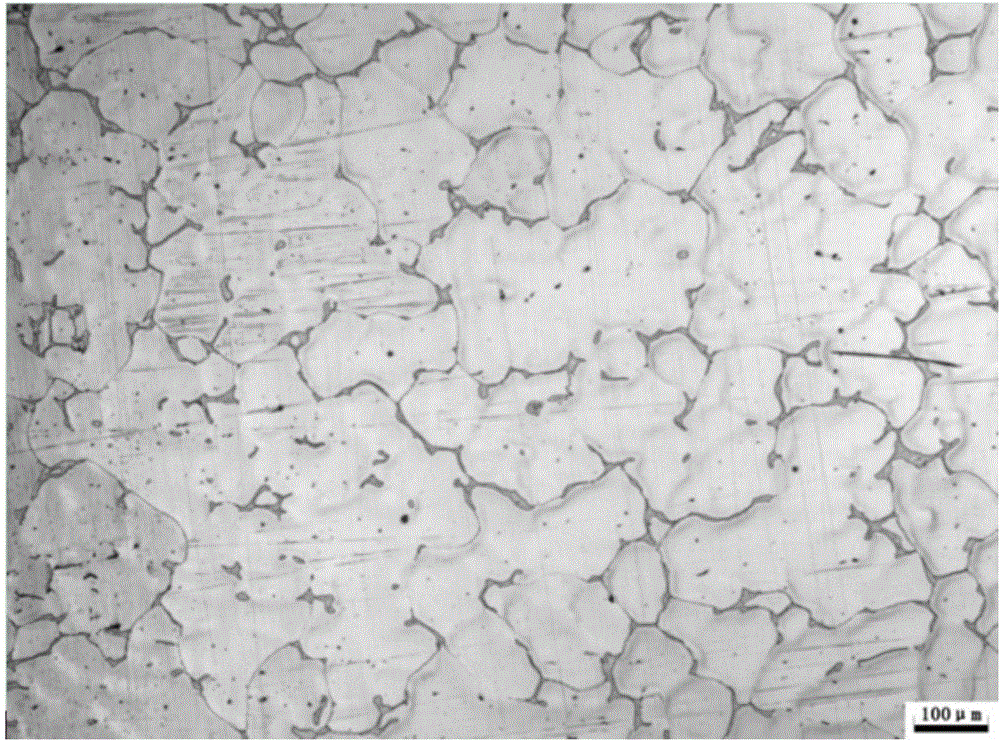

[0045] attached figure 2 and image 3 The high-magnification structures of 4# ingot (29.6Cr-5.2Mo) and 13# ingot (24.3Cr-7.4Mo) are shown respectively. It can be seen that the segregation degree of 13# ingot (24.3Cr-7.4Mo) is obviously higher than that of 4# ingot due to the low ch...

Embodiment 2

[0048] Example 2 Mechanical properties of high chromium austenitic stainless steel

[0049] attached Figure 7 The mechanical properties of N on high chromium austenitic stainless steel are shown. It can be seen that the strength of high chromium austenitic stainless steel increases with the increase of nitrogen. When the N content reaches above 0.6, the yield strength of the plate can reach above 600MPa. When the N content is higher than 0.9, the impact toughness value at -40°C is lower than 27J, which has no practical engineering application value. The nitrogen content is controlled between 0.60 and 0.90, and high-chromium austenitic stainless steel can obtain good mechanical properties.

Embodiment 3

[0050] Example 3 Localized corrosion resistance of high chromium austenitic stainless steel

[0051] Figure 8 The relationship between the critical crevice corrosion temperature of high-chromium austenitic stainless steel and the value of pitting resistance index PREN is shown. It can be seen that as the PREN value of high-chromium austenitic stainless steel increases, the critical crevice corrosion resistance of stainless steel increases, indicating that its Improved resistance to localized corrosion. When the PREN value is greater than 68, its critical crevice corrosion temperature reaches 60°C and above, which is already higher than the existing 7Mo super austenitic stainless steel 654SMO.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| reduction of area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com