A kind of production method of high-strength boron-containing steel plate

A production method and high-strength technology, applied in the field of steel plate production, can solve the problems of low tensile strength and yield strength, low elongation at break, and achieve good toughness, increased strength, and improved antirust performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

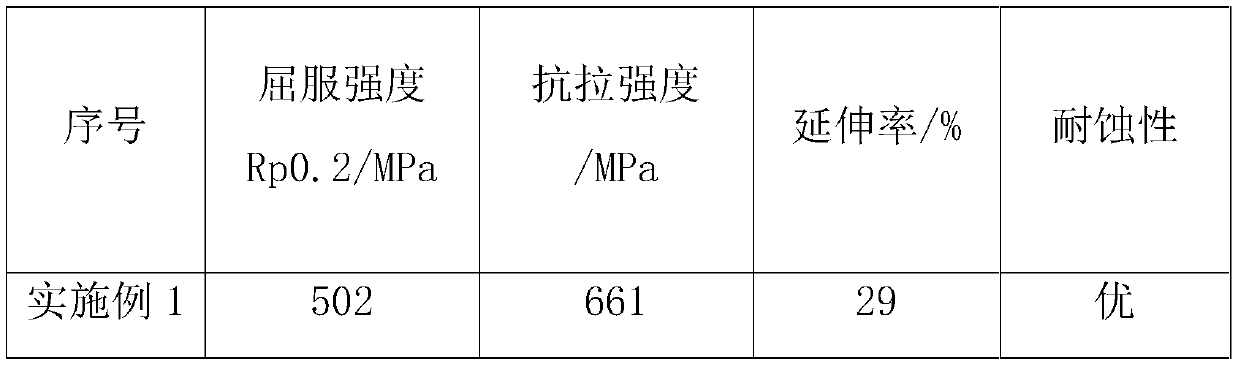

Embodiment 1

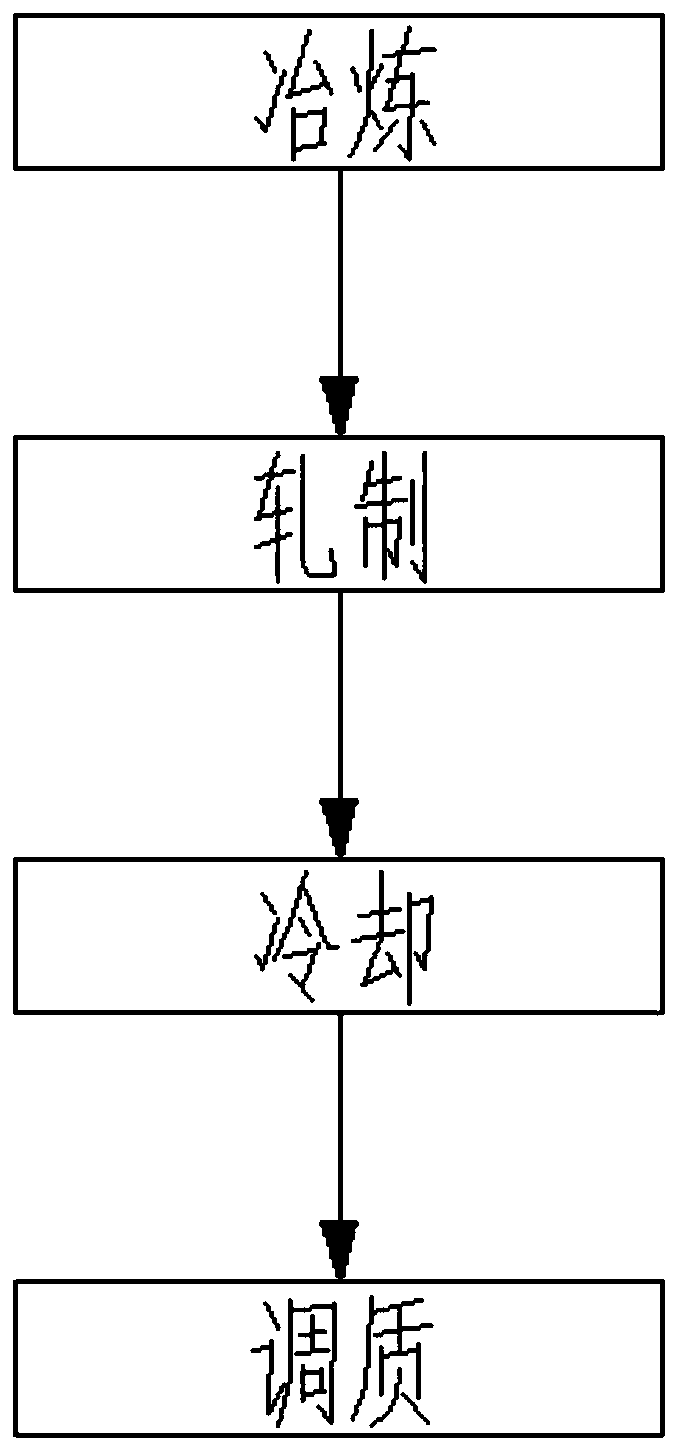

[0026] Such as figure 1 As shown, a production method of high-strength boron-containing steel plate, the chemical composition mass ratio of the steel plate is C: 0.12%, Si: 0.45%, Mn: 1.5%, P: 0.02%, S: 0.005%, Al : 0.010%, Cr: 0.1%, Nb: 0.02%, N: 0.003%, Mo: 0.6%, B: 0.0020%, and the rest are Fe and unavoidable impurities. The production method is carried out according to the following steps,

[0027] (1) Smelting and pouring into slabs according to the above composition, and then hot rolling at 1080°C, controlling the single-pass deformation to 30%, then pickling, and then cold rolling by 50%, and the cold rolling temperature is 925°C;

[0028] (2) The steel plate after rolling is cooled to 560°C with online oil at a cooling rate of 20°C / s, and then air-cooled to room temperature;

[0029] (3) The rolled steel plate is reheated to 960°C for 4 minutes, then water-cooled and quenched, tempered at 600°C for 2 hours after quenching, the steel plate is taken out and pickled, and...

Embodiment 2

[0030] Embodiment 2: the rest are the same as in Example 1, the difference is that in the step (1), the hot rolling temperature is 1055°C, the single pass deformation is 26%, the cold rolling temperature is 935°C, and the cold rolling deformation 50%; in the step (2), the cooling rate is 16°C / s, and the oil is cooled to 550°C; in the step (3), the rolled steel plate is heated to 955°C, kept for 4 minutes, and tempered The temperature is 600°C and the temperature is kept for 3 hours.

Embodiment 3

[0031] Embodiment 3: the rest are the same as in Example 1, the difference is that in the step (1), the hot rolling temperature is 1100°C, the single pass deformation is 30%, the cold rolling temperature is 935°C, and the cold rolling deformation 40%; in the step (2), the cooling rate is 20°C / s, and the oil is cooled to 580°C; in the step (3), the rolled steel plate is heated to 965°C, kept for 4 minutes, and tempered The temperature was 590°C and the temperature was kept for 2.4 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com