Automobile exhaust pipe with good silencing function

A technology for automobile exhaust and noise reduction, applied in the field of auto parts, can solve the problems of complex structure and inconvenient installation of the muffler, and achieve the effects of simple structure, elimination of harmful gases, and reduction of imaging pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

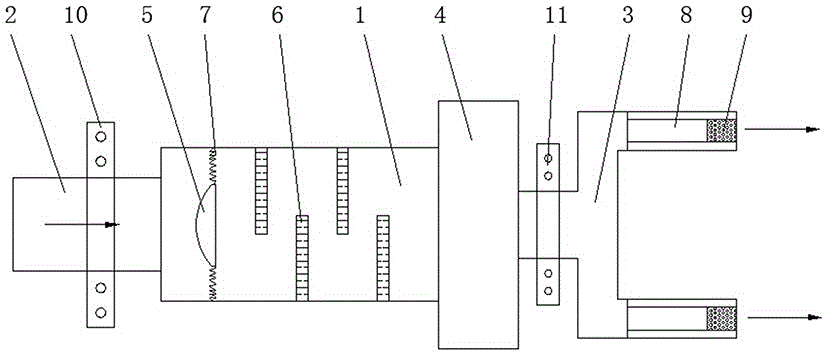

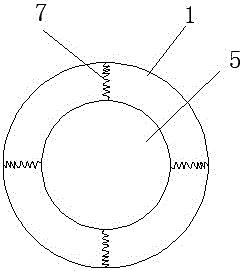

[0020] A kind of automobile exhaust pipe with good sound-absorbing function described in the present invention, as figure 1 As shown, it includes: a main pipe 1, an inlet pipe 2 arranged at the front end of the main pipe 1, and a tail pipe 3 at the end; an exhaust gas purifier 4 is arranged between the main pipe 1 and the tail pipe 3; an airflow buffer is provided in the main pipe 1 Plate 5 and filter unit 6; the airflow buffer plate 5 is arranged at the front end of the filter unit 6, and is located at the axis of the intake pipe 2; the airflow buffer plate 5 is connected to the inner wall of the main pipe 1 by a spring 7; wherein , the airflow buffer plate 5 is in the shape of a "pot cover", and the raised part is located in the direction of the intake pipe 2. The filter unit 6 is alternately distributed up and down in the horizontal direction; the tailpipe 3 is provided with two exhaust branch pipes 8; the exhaust branch pipe 8 is a double-layer structure, and the inner tai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com