Single mode four-stroke minitype water-cooling oil gas electricity generating engine

A power generation engine, four-stroke technology, applied in the direction of engine components, machines/engines, engine starting, etc., to achieve the effects of small size, easy portability, and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

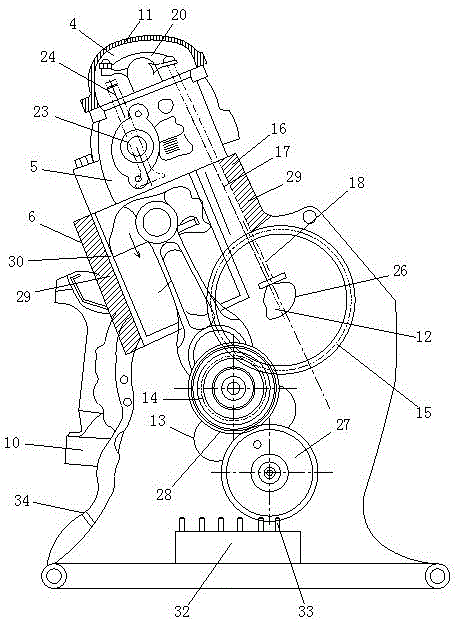

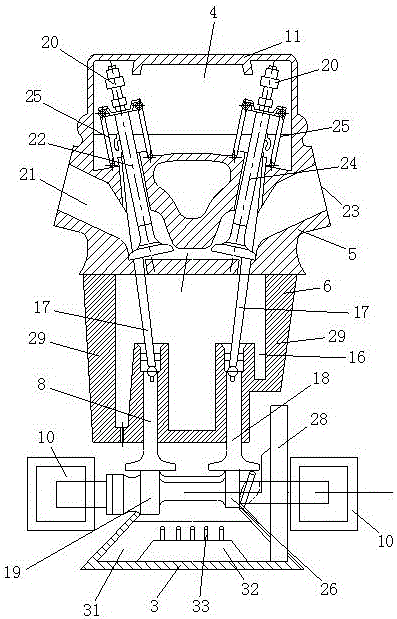

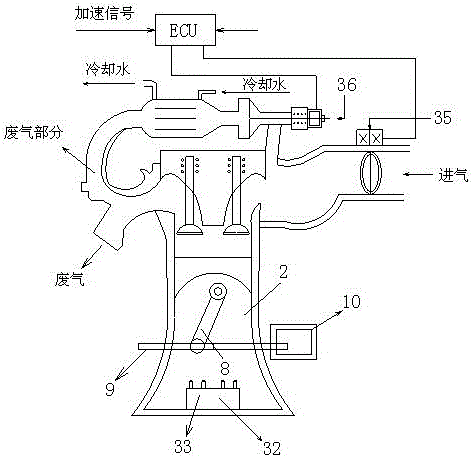

[0024] refer to Figure 1-10 , the specific embodiment adopts the following technical solutions: a single-mode four-stroke miniature water-cooled oil-gas power generation engine, including a cylinder, a combustion chamber 1, a crank chamber 2, a lubricating oil chamber 3, a rocker chamber 4 and a power supply system, and the rear portion of the cylinder is provided with The combustion chamber 1 is provided with a rocker chamber 4 on the top of the cylinder, and the crank chamber 2 is provided on the bottom of the cylinder, and the bottom of the crank chamber 2 is a lubricating oil chamber 3; The cylinder head 5 is equipped with a cylinder head cover 11 on the upper end of the cylinder head 5, a crank chamber 2 is provided on the bottom of the cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com