Ultra-supercritical secondary reheating generator unit reheating steam temperature compound control strategy

A technology of secondary reheating and reheating steam temperature, which is applied in the control of superheated temperature, steam superheating, steam generation, etc., can solve the problems of the influence and complexity of the thermal characteristics of the unit, and the dependence of the dynamic and static response characteristics of the unit is enhanced. Accelerate the adjustment response speed, avoid mutual interference, and improve the effect of adjustment quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in more detail below in conjunction with the accompanying drawings and specific embodiments.

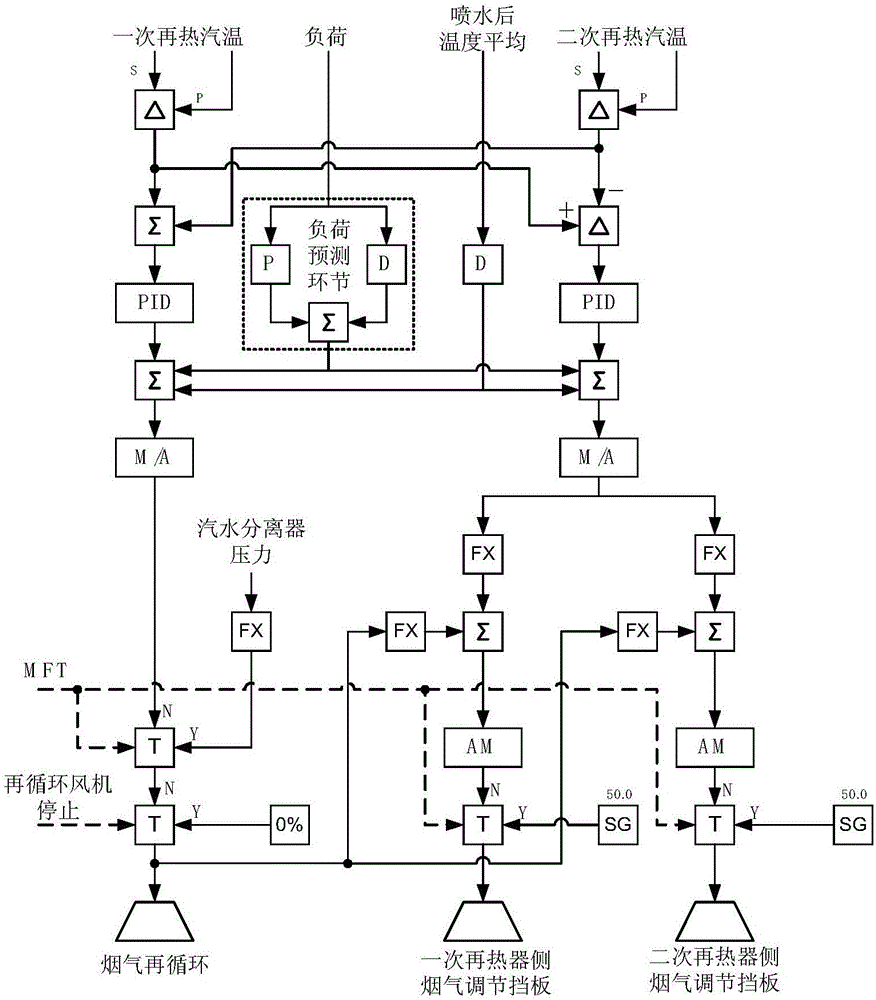

[0016] At present, the double reheating units put into operation in my country often adopt π-type and full-suspension structures. The binoculars at the rear are arranged and equipped with a flue gas baffle to adjust the flue gas distribution of the front and rear flues. Set the flue gas in the circulation system after the economizer as a means of adjusting the temperature of the low-load reheating steam. The primary and secondary reheating steam systems are arranged according to the high and low temperature levels. The high temperature reheaters are arranged from the horizontal eye to the upper part, and the low temperature reheaters are arranged countercurrently in the front and rear shafts from the tail eye. An emergency sprinkler desuperheater is also installed on the reheater link pipe. The temperature adjustment of the first and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com