Electronic detonator initiation system based on near field communication and control method of electronic detonator initiation system

An electronic detonator and near-field communication technology, which is applied in blasting and other directions, can solve the problems of large work of retracting and releasing lines, increasing the preparation period and manual workload of the project site, and high cost of single-shot wireless electronic detonators, so as to improve work reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be further elaborated below through specific embodiments in conjunction with the accompanying drawings.

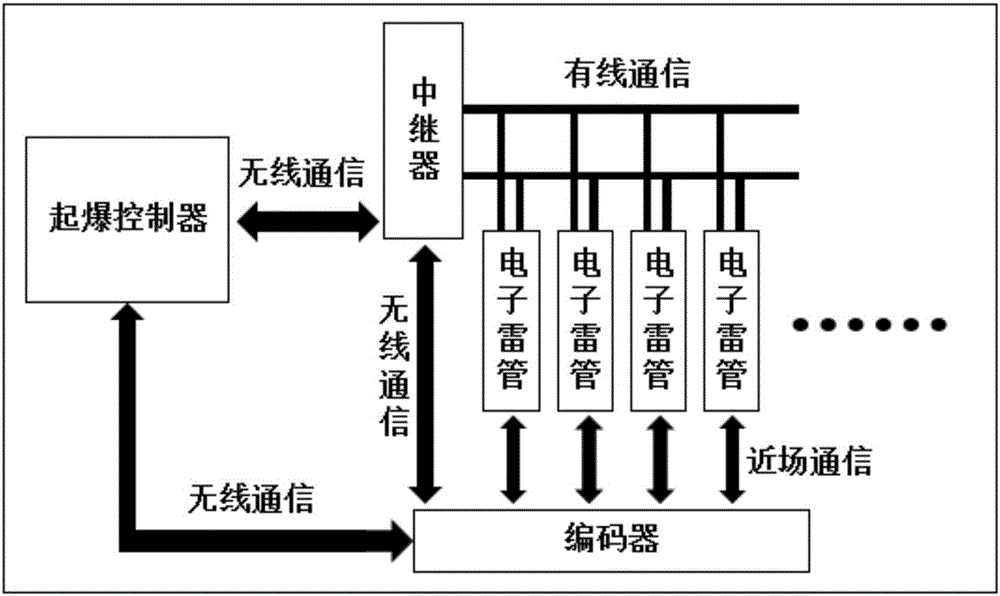

[0053] Such as figure 1 As shown, the electronic detonator detonation system based on near-field communication in this embodiment includes: a detonation controller, an encoder, a repeater and an electronic detonator; wherein, the detonation controller controls one or more branches; each branch includes An encoder, one or more repeaters, and multiple electronic detonators; each electronic detonator is connected to the repeater through a signal bus to form a wired detonation network, and the detonation controller and encoder communicate wirelessly with the repeater. The repeater communicates with the electronic detonator by wire to form the detonation network of the electronic detonator detonation system.

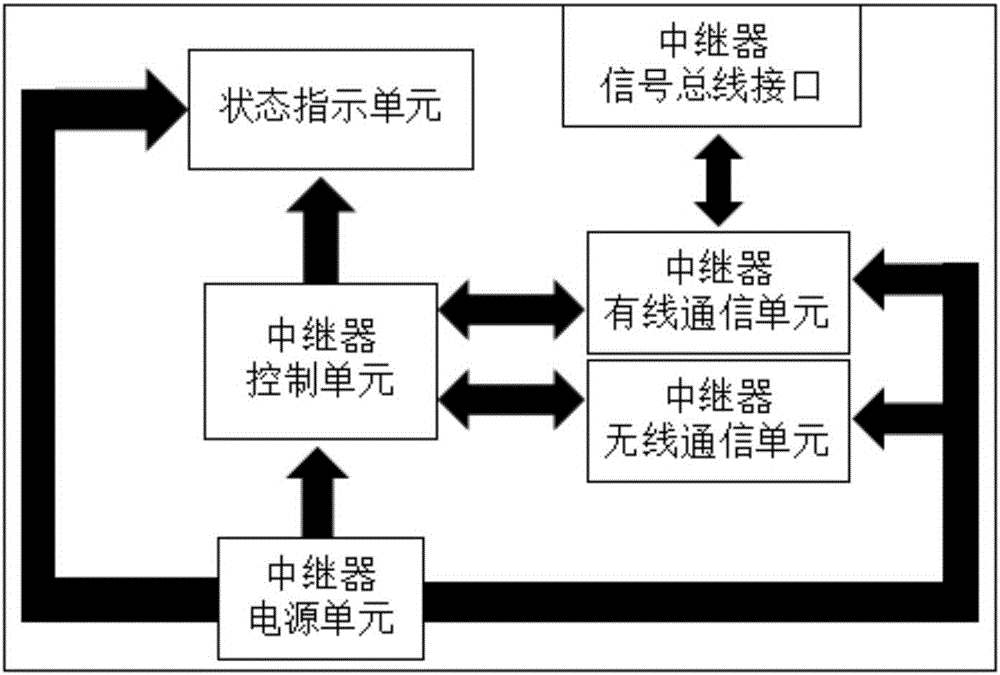

[0054] Such as figure 2 As shown, the repeater includes a repeater control unit, a repeater wired communication unit, a repeater wire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com