Graphene-based strain sensing film and preparation method and application thereof

A strain sensing, graphene-based technology, applied in the direction of electric/magnetic solid deformation measurement, electromagnetic measurement devices, etc., can solve the problem that the level of strain sensor technology has not achieved major breakthroughs, graphene nanosheets are not tightly packed, graphene nanometers It can improve the reusability, high transparency and compact stacking effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

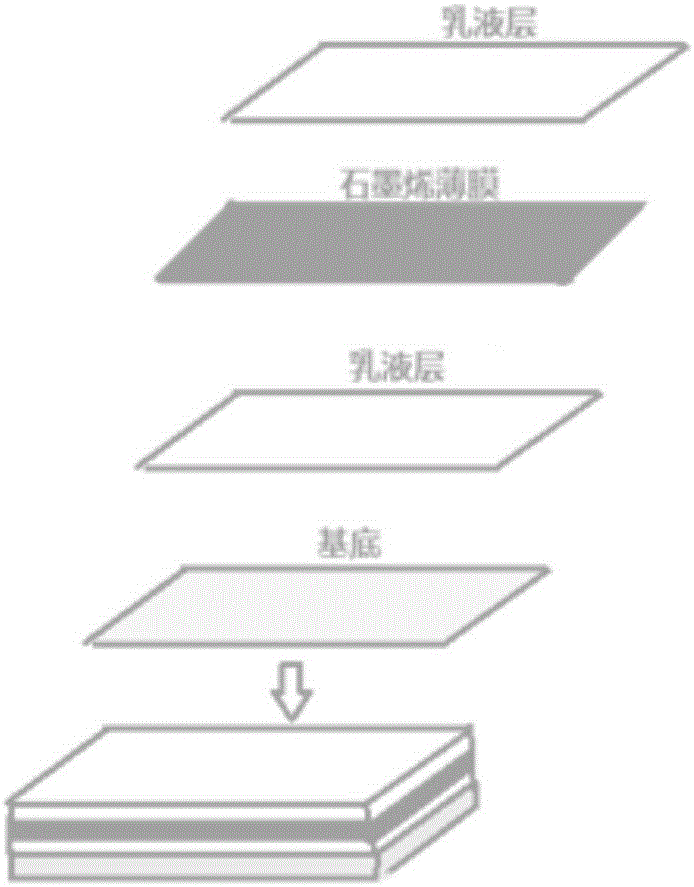

[0042] (1) Measure 10ml PX 7026X ap (solid content 50%) was added to 10mL deionized water, and after magnetic stirring for 10min, a diluted emulsion was obtained. Take 1.5mL of the above-mentioned diluted emulsion, and spray it on the rubber sheet substrate with a spray gun to facilitate strain transmission. Sensitivity test, in which the size of the rubber sheet is 100mm×15mm, and the amount of emulsion spraying is about 555g / m 2 ;

[0043] (2) Weigh 500mg of graphene raw material as C750 (XG Science Inc., USA) and add it to 1000mL of deionized water, after magnetic stirring for 30min, ultrasonic treatment for 2h to obtain graphite with good dispersibility and a concentration of 0.5mg / mL olefin dispersion, the spraying amount is 0.1g / m 2 , using a spray gun to spray a graphene dispersion on the emulsion coating to form a graphene film;

[0044] (3) Take 0.45mL of the emulsion diluted in (1), and spray it on the graphene film with a spray gun. The amount of emulsion sprayi...

Embodiment 2

[0047] (1) Measure 10ml PX 7026X ap (solid content 50%) was added to 10mL deionized water, and after magnetic stirring for 10min, a diluted emulsion was obtained. Take 1.5mL of the above-mentioned diluted emulsion, and spray it on the rubber sheet substrate with a spray gun to facilitate strain transmission. Sensitivity test, in which the size of the rubber sheet is 100mm×15mm, and the amount of emulsion spraying is about 555g / m 2 ;

[0048] (2) Weigh 500mg of graphene raw material as C750 (XG Science Inc., USA) and add it to 1000mL of deionized water, after magnetic stirring for 30min, ultrasonic treatment for 2h to obtain graphite with good dispersibility and a concentration of 0.5mg / mL olefin dispersion, the spraying amount is 0.1g / m 2 , using a spray gun to continue spraying the graphene dispersion on the emulsion coating to form a graphene film;

[0049] (3) Take 0.75mL of the emulsion diluted in (1), and spray it on the graphene film with a spray gun. The amount of e...

Embodiment 3

[0052] (1) Measure 10ml PX 7026X ap (solid content 50%) was added to 10mL deionized water, and after magnetic stirring for 10min, an emulsion was obtained. Take 1.5mL of the above emulsion, and use a spray gun to spray it on the rubber sheet substrate to facilitate the test of strain sensing performance. The size of the rubber sheet is 100mm×15mm, and the amount of emulsion spraying is about 555g / m 2 ;

[0053] (2) Weigh 500mg of graphene raw material as C750 (XG Science Inc., USA) and add it to 1000mL of deionized water, after magnetic stirring for 30min, ultrasonic treatment for 2h to obtain graphite with good dispersibility and a concentration of 0.5mg / mL olefin dispersion, the spraying amount is 0.1g / m 2 , using a spray gun to continue spraying the graphene dispersion on the emulsion coating to form a graphene film;

[0054] (3) Take 3mL of the emulsion in (1), and use a spray gun to spray it on the graphene film. The amount of emulsion spraying is about 1110g / m 2 ; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com