A method for patterning platelets on the surface of materials using polyphenolic compounds

A technology of polyphenolic compounds and polyphenolic compounds, which is applied in the direction of analysis materials, test sample preparation, sampling, etc., can solve the problem of platelet adhesion that has not been seen yet, and achieve the effect of low cost, simple and fast operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

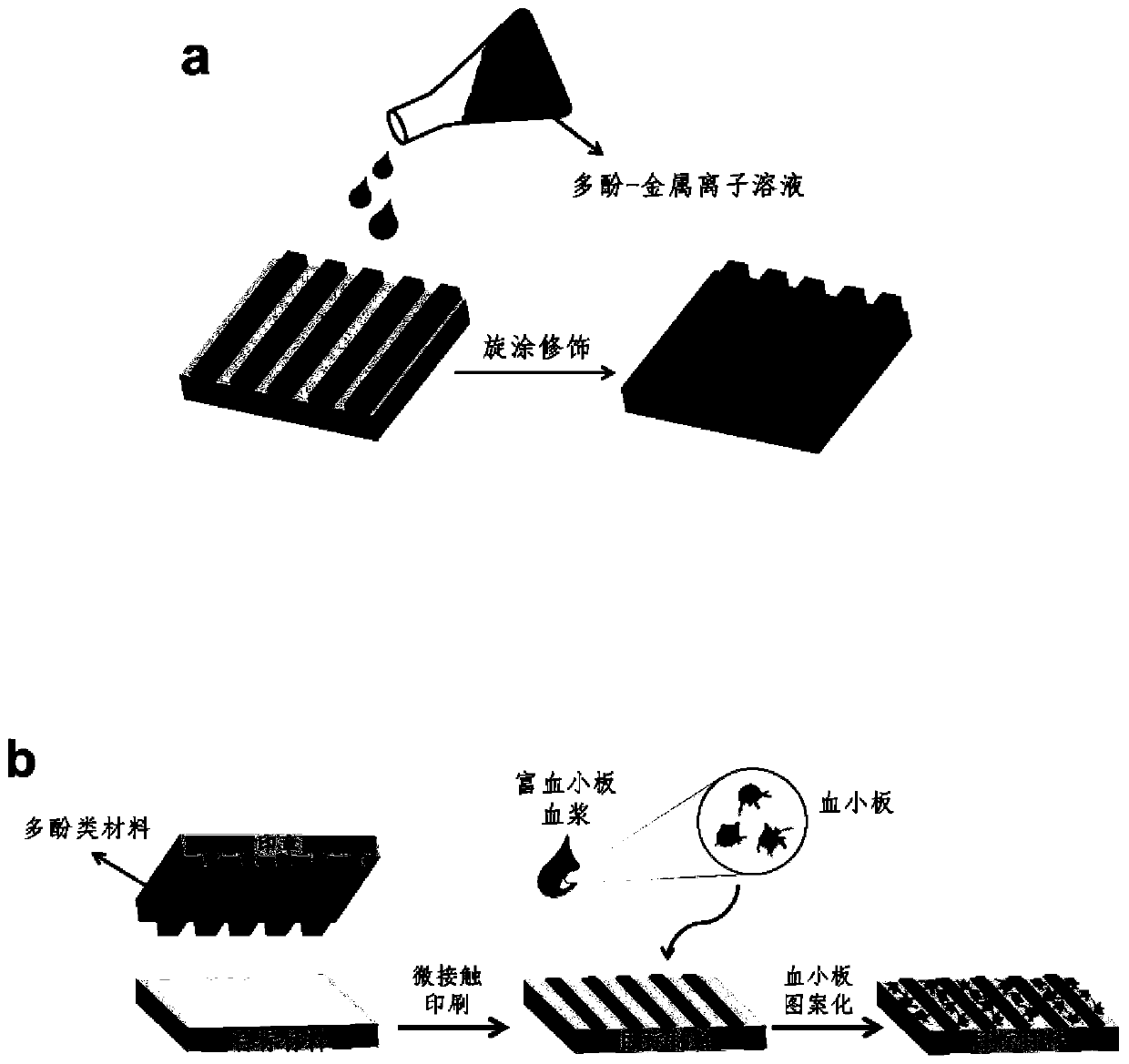

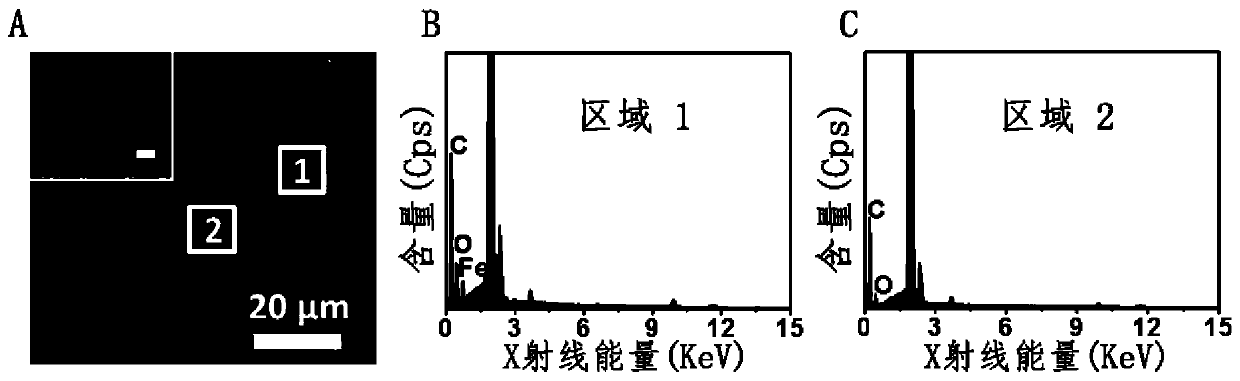

[0031] 1) With 50% aqueous ethanol as a solvent, configure a concentration of 3.2 mg / mL of tannic acid solution and 0.8 mg / mL ferric chloride solution respectively, then mix the two solutions in equal volumes to obtain tannic acid- Iron ion solution ( figure 1 a);

[0032] 2) Add the tannic acid-iron ion solution dropwise to the surface of the silicone rubber stamp ( figure 2 ), using a spin coater to modify the surface of the stamp ( figure 1a), the parameters of the spin coater are controlled at 2000rpm / min, and the total drip volume of the tannic acid-iron ion solution is 1mL / mm 2 , the modification time is 3min;

[0033] 3) The surface of the stamp modified with tannic acid material is attached to the surface of the target material silicon wafer, so that the tannic acid material is transferred to the surface of the silicon wafer, and the stamp is removed after 10 minutes to obtain a silicon wafer with a micro-pattern of tannic acid surface;

[0034] 4) A silicon wafe...

Embodiment 2

[0038] 1) With 50% aqueous ethanol as a solvent, configure a concentration of 0.8 mg / mL epicatechin gallate solution and a 0.8 mg / mL ferric chloride solution respectively, then mix the two solutions in equal volumes to obtain Epicatechin gallate-iron ion solution;

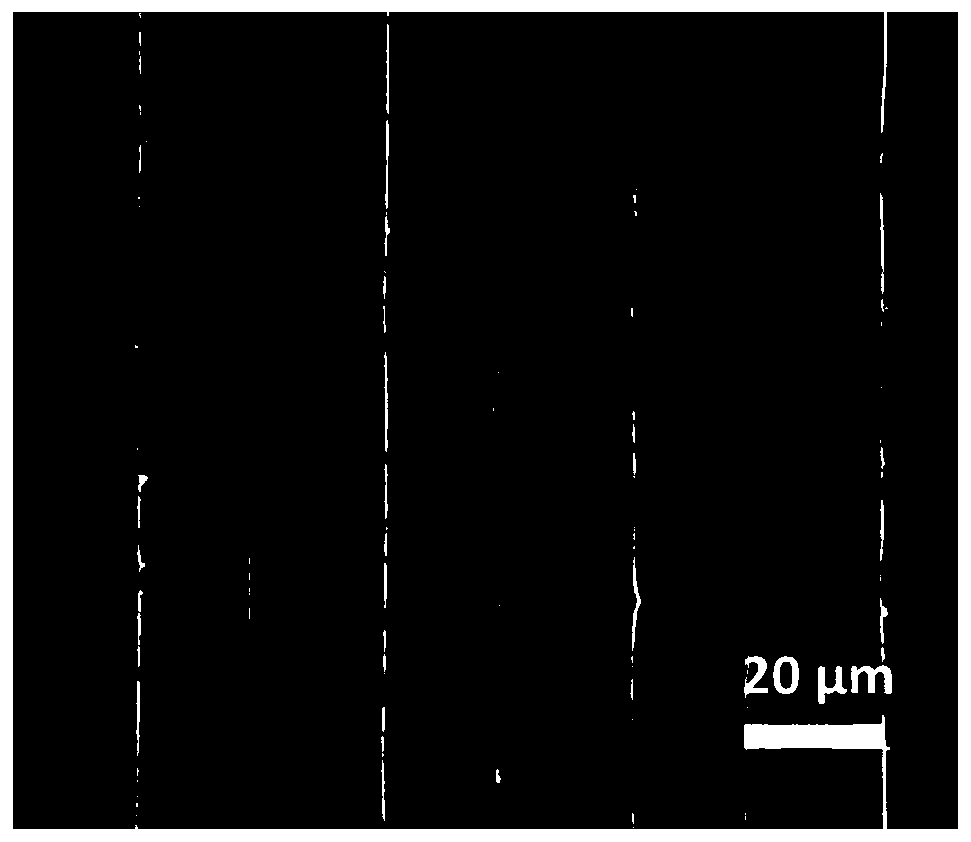

[0039] 2) Add epicatechin gallate-iron ion solution dropwise to the surface of the silicone rubber stamp with a micro-pattern (strip interval of 20 microns), and use a spin coater to modify the surface of the stamp, and the parameters of the spin coater are controlled At 2000rpm / min, the total drip volume of epicatechin gallate-iron ion solution is 1mL / mm 2 , the modification time is 3min;

[0040] 3) The surface of the stamp modified with the epicatechin gallate material is attached to the surface of the silicon wafer of the target material, so that the epicatechin gallate material is transferred to the surface of the silicon wafer, and the stamp is removed after 10 minutes to obtain a Silicon wafer surface micr...

Embodiment 3

[0043] 1) Using 50% aqueous ethanol as a solvent, prepare respectively an epigallocatechin gallate solution with a concentration of 3.2 mg / mL and a ferric chloride solution with a concentration of 0.8 mg / mL, then mix the two solutions in equal volumes, Obtaining epigallocatechin gallate-iron ion solution;

[0044] 2) Add epigallocatechin gallate-iron ion solution dropwise to the surface of the silicone rubber stamp with a micro-pattern (strip interval of 20 microns), and use a spin coater to modify the surface of the stamp. The parameters of the spin coater Controlled at 2000rpm / min, the total drip volume of epigallocatechin gallate-iron ion solution is 1mL / mm 2 , the modification time is 3min;

[0045] 3) The surface of the stamp modified with the epigallocatechin gallate material is attached to the surface of the silicon wafer of the target material, so that the epigallocatechin gallate material is transferred to the surface of the silicon wafer, and the stamp is removed af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com