Electrochemical performance detection system and photoelectrochemical performance detection system

A detection system and electrochemical technology, applied in the field of electrochemical and photoelectrochemical detection, can solve problems such as operational errors, cumbersome and long processes, and achieve the effect of avoiding contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

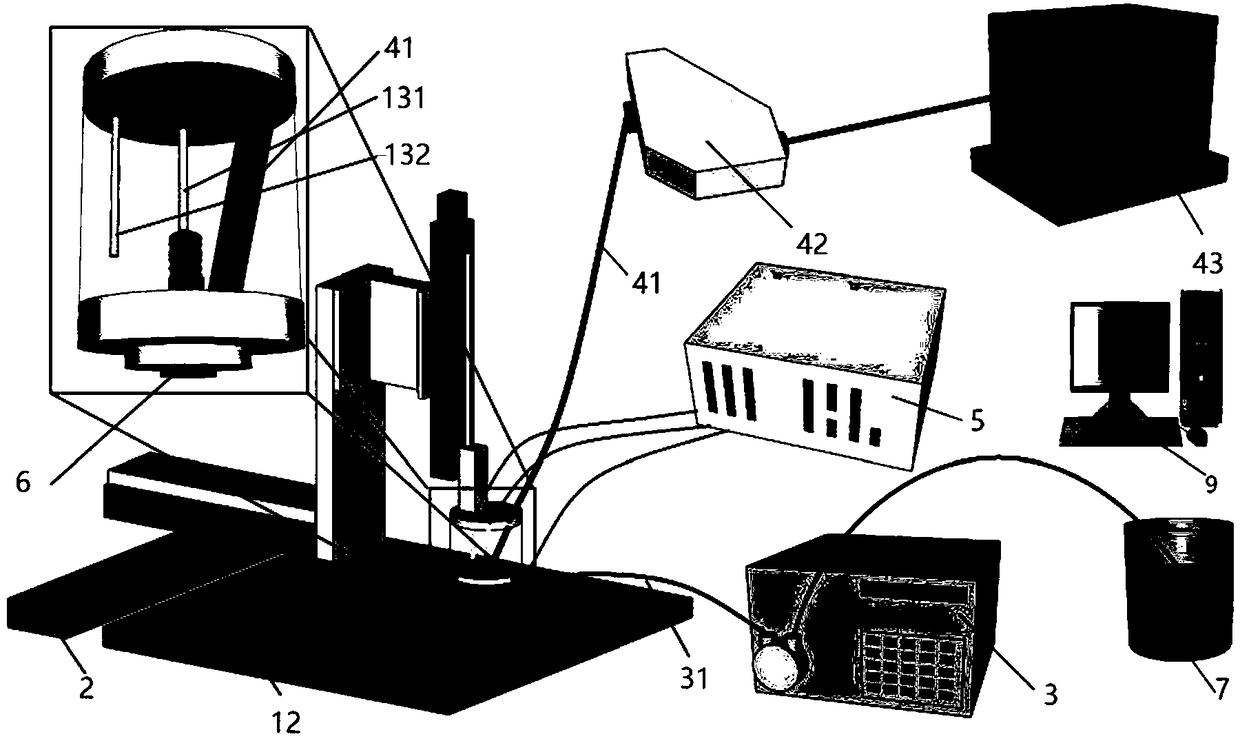

[0053] figure 1 A preferred embodiment of a photoelectrochemical performance detection system according to the present invention is shown. In this embodiment, the photoelectrochemical performance detection system includes a workstation 1 , a brake component 2 , a liquid transmission component 3 , a light source component 4 , a voltage regulator 5 and a control component 9 . The workstation 1 includes an electrochemical cell, a sample stage 12, an electrode device and a gas delivery device.

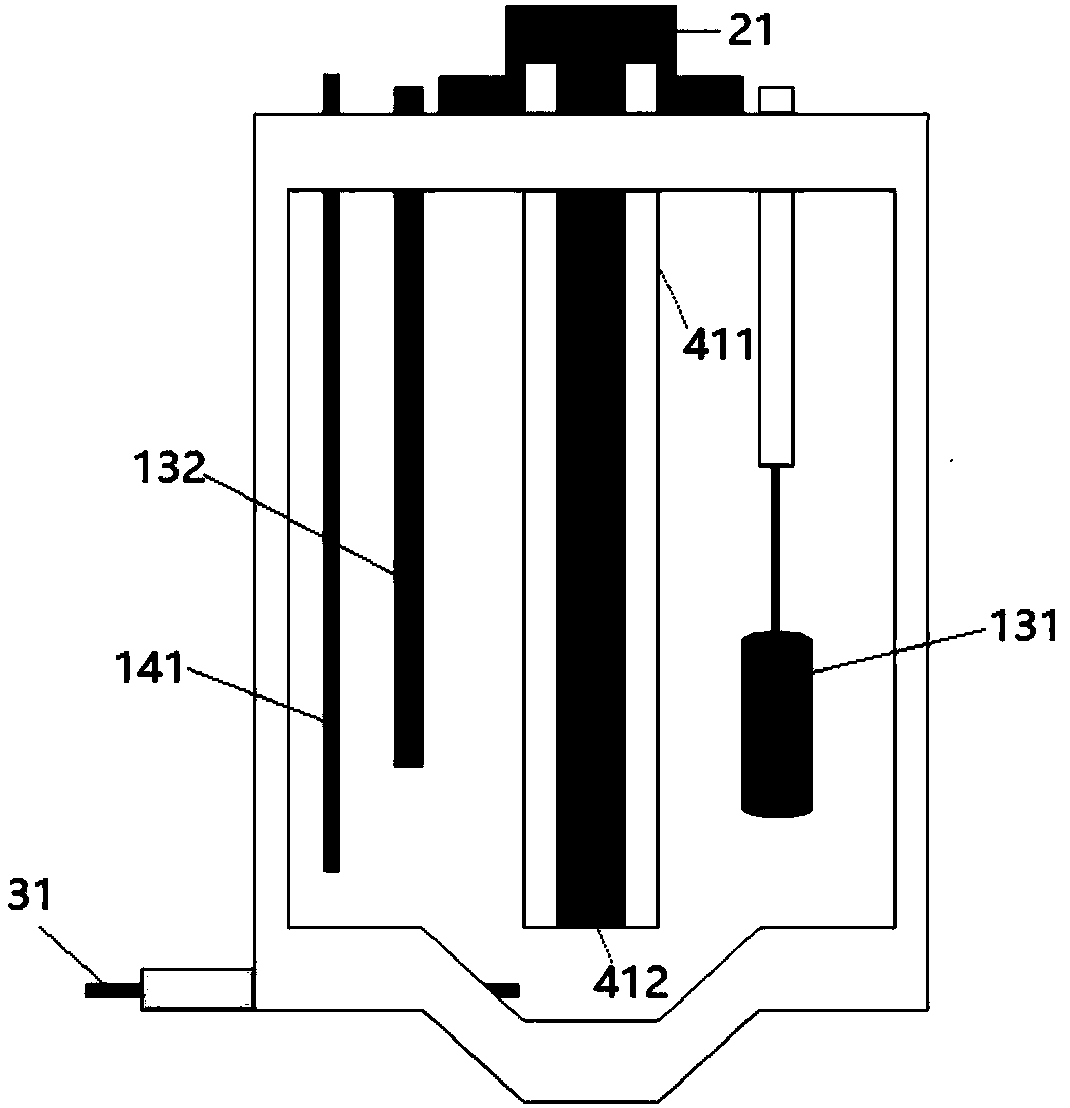

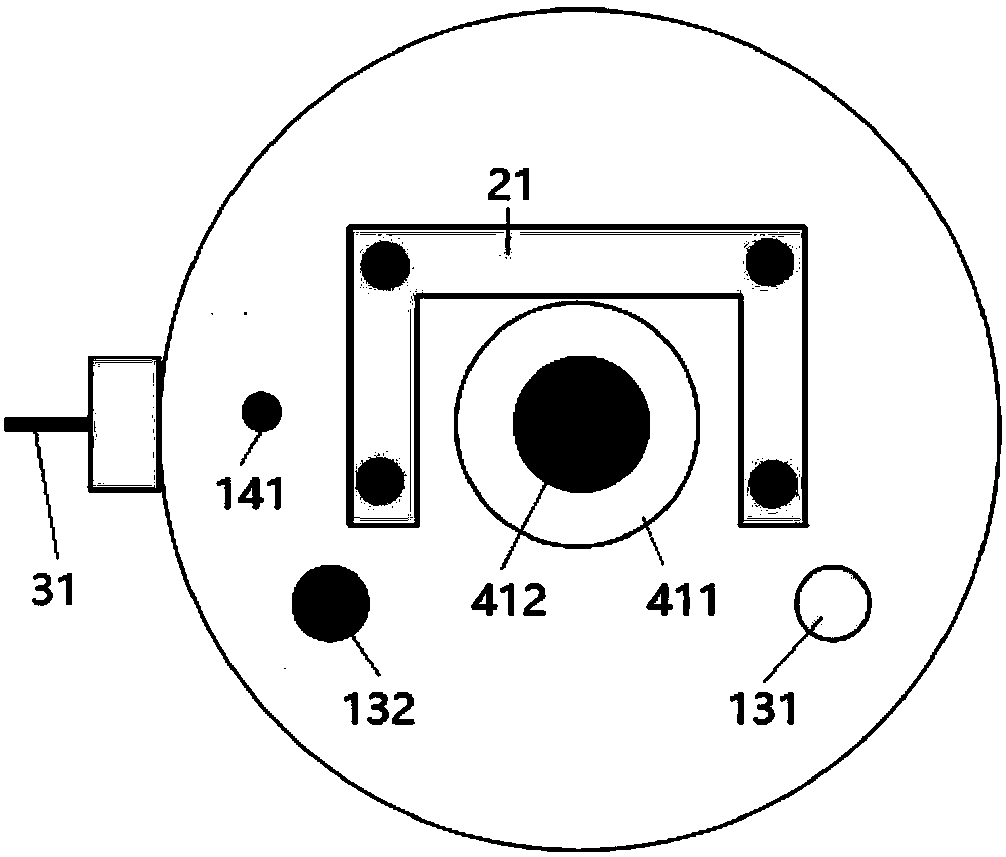

[0054] Figure 2-4 A preferred embodiment of the electrochemical cell is shown. The electrochemical cell is provided with an elastic element, a first through hole 111 and a second through hole. The bottom of the electrochemical cell is conical, and the first through hole 111 is located at the tip of the conical bottom. A sealing ring 113 is disposed on the first through hole 111 . The elastic element is arranged on the top of the electrochemical cell, and its telescopic direction is c...

Embodiment 2

[0077] In this embodiment, the first through hole is disposed on the side wall of the electrochemical cell. And the side wall of the electrochemical cell provided with the first through hole is tapered, and the first through hole is located at the tip of the tapered shape. Therefore, in this embodiment, the sample stage can be set to be placed vertically, so that the sample in the sample stage is docked with the first through hole. All the other are the same with embodiment 1.

Embodiment 3

[0079] In this embodiment, the electrochemical cell includes a first electrolytic cell, a salt bridge, and a second electrolytic cell connected in sequence, which are H-shaped or n-shaped; the counter electrode and the reference electrode are arranged in the first electrolytic cell; the first through A hole is provided in the second electrolytic cell. Salt bridges are sand cores. The second through hole and the gas delivery pipe on the gas delivery device can be arranged in either the first electrolytic cell or the second electrolytic cell. All the other are the same with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com