An ultrasonic phased array online testing method for the internal quality of thin-walled CFRP pipe fittings

An ultrasonic phased array, on-line testing technology, applied in the analysis of solids using sonic/ultrasonic/infrasonic waves, material analysis using sonic/ultrasonic/infrasonic waves, measurement devices, etc., to improve detection accuracy, avoid adverse effects, and improve detection efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

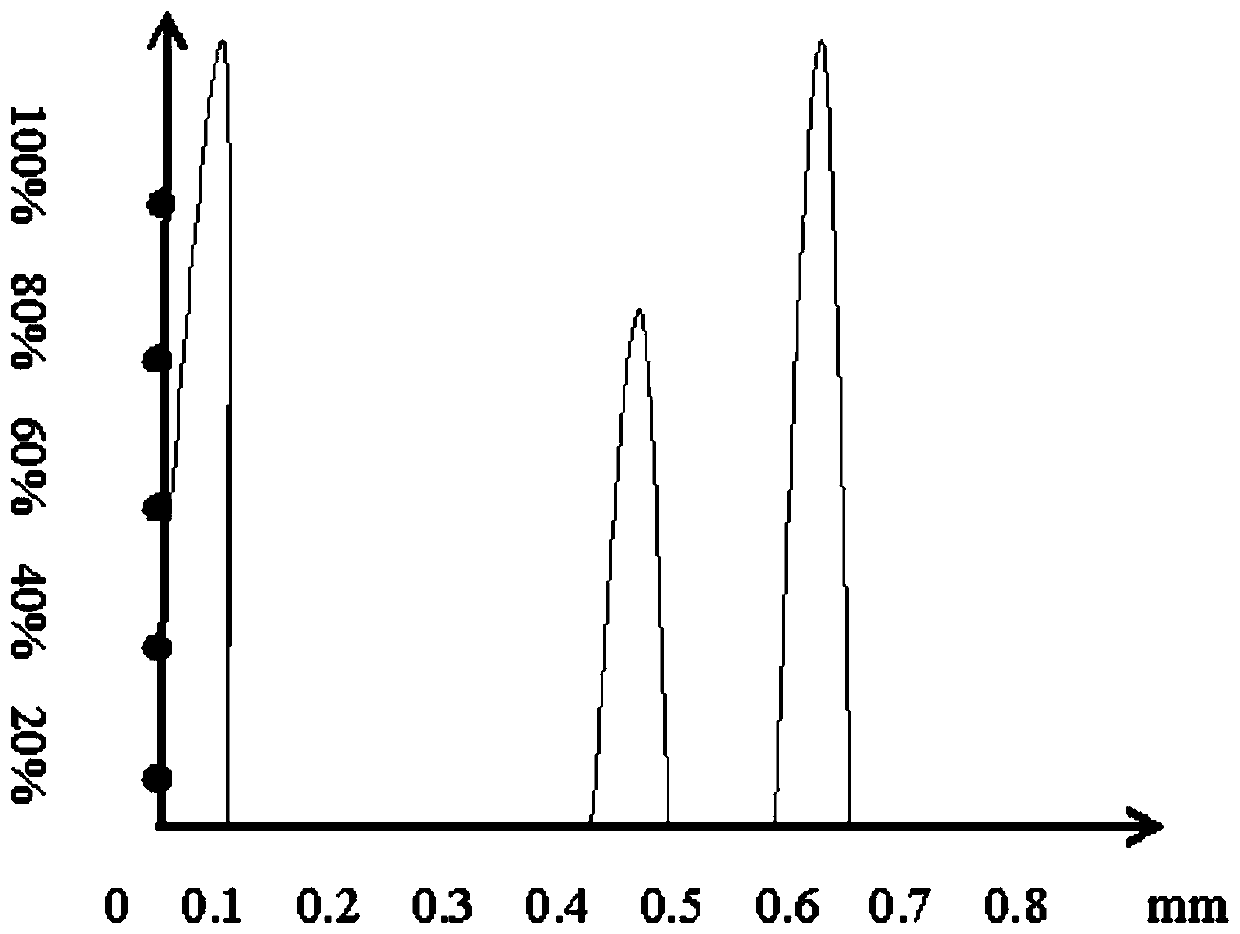

[0062] The seven-layer wound loop antenna structure with an outer wall diameter of 26 mm and a wall thickness of 0.6 mm was tested with a thin-walled CFRP pipe for ultrasonic phased array testing. It is required that there are no defects larger than 0.5mm equivalent in CFRP pipe fittings. The steps of the method include:

[0063] (1) Prepare standard comparison specimens of CFRP pipe fittings with defects;

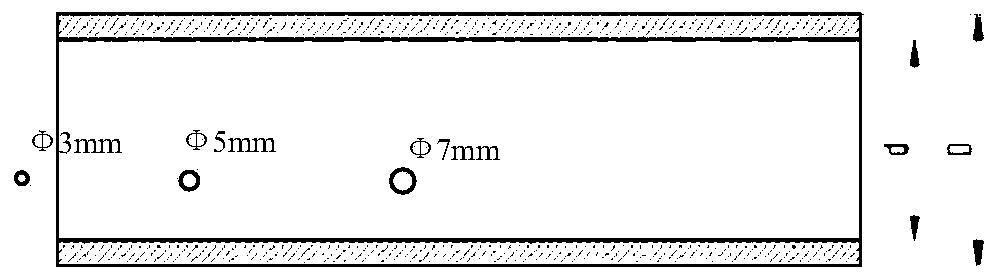

[0064] The preparation method is: in the process of preparing CFRP thin-walled pipe fittings by winding method, place two single layers with sizes of Φ3mm, Φ5mm, and Φ7mm and a thickness of 0.02mm between the sixth and seventh layers of CFRP PTFE film, the function of placing the PTFE film is to isolate CFRP, and the position where the PTFE film is placed is the defect position, such as figure 1 shown;

[0065] (2) carry out ultrasonic phased array test to the standard comparative specimen prepared in step (1);

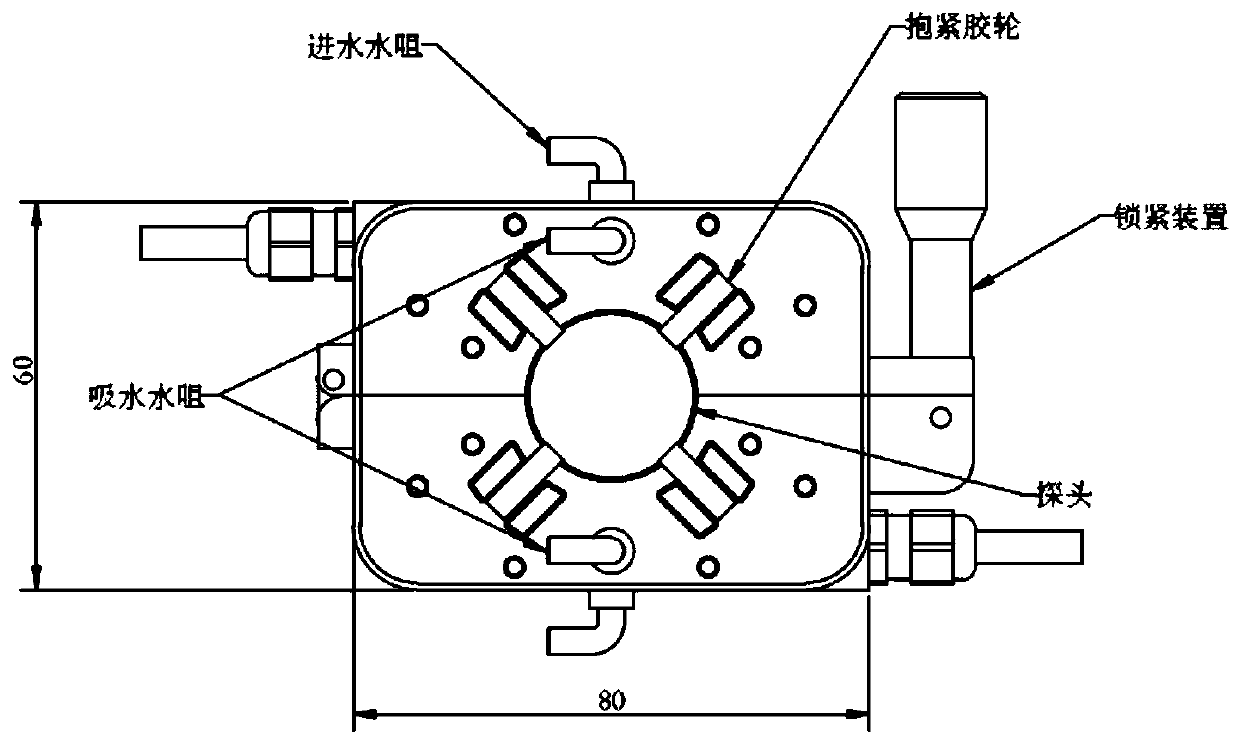

[0066] The ultrasonic phased array test method is as fol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com