Photocatalytic in-situ characterization system

A photocatalytic, in-situ technology, applied in the direction of chemical analysis using catalysis, can solve problems such as the inability to reflect the real situation of the photocatalytic reaction process and the inability of testing methods to meet the requirements of photocatalytic research.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings. However, those skilled in the art know that the present invention is not limited to the drawings and the following embodiments.

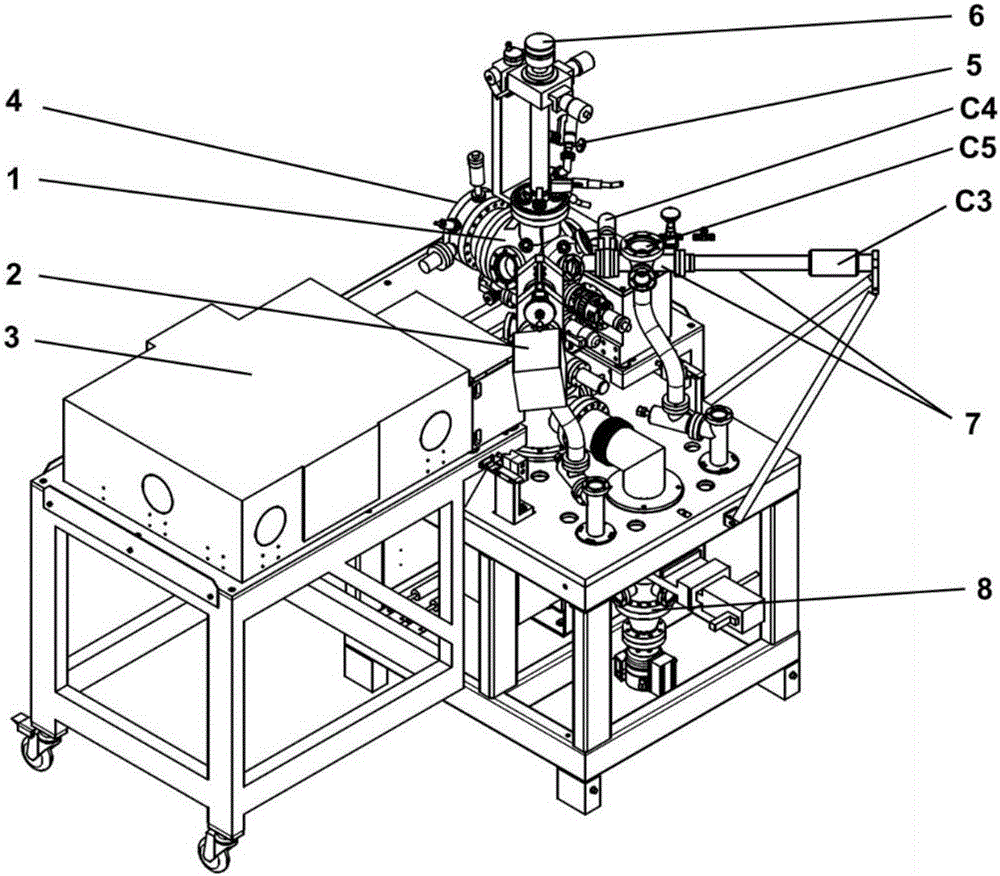

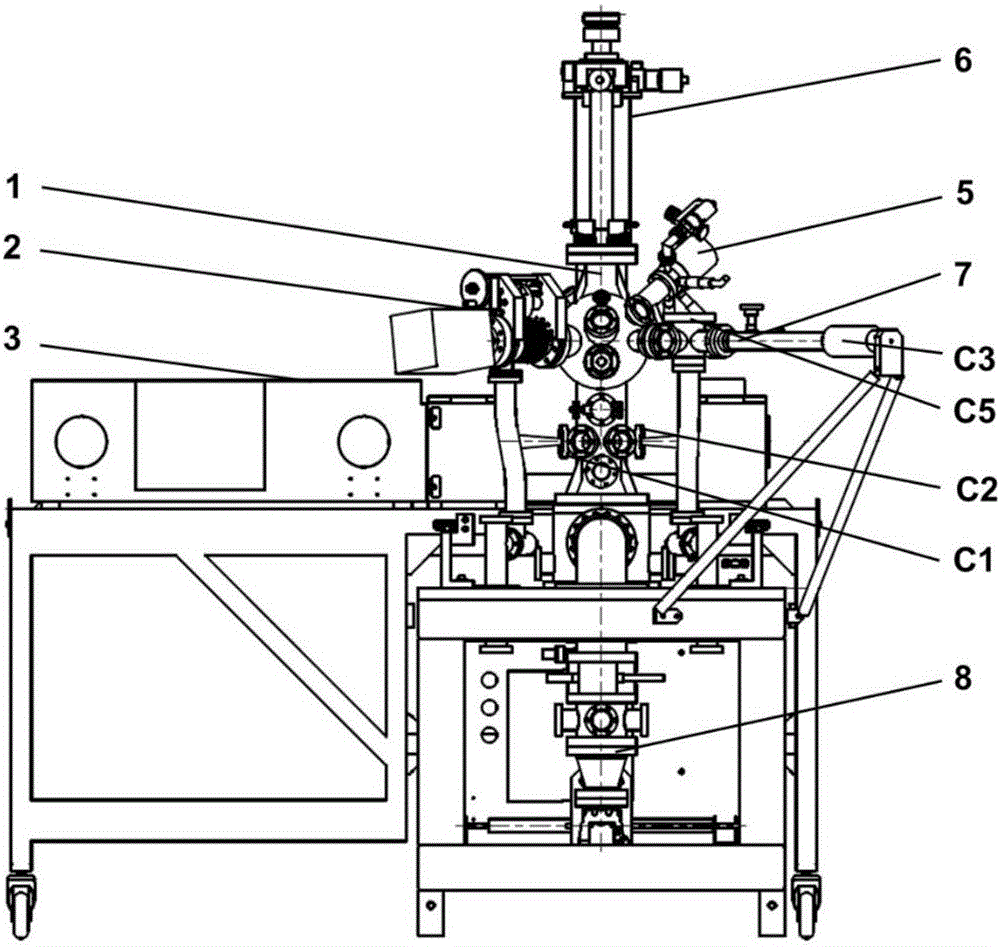

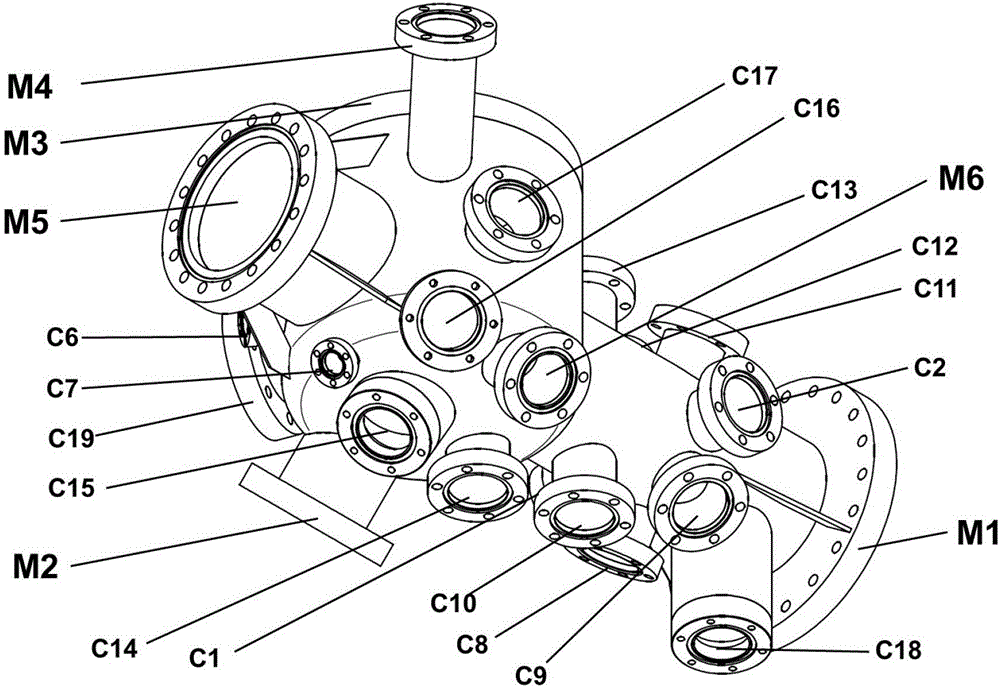

[0041] Such as Figure 1-4 As shown, a photocatalytic in situ characterization system for surface and interface research of photocatalytic reactions, the photocatalytic in situ characterization system is built on the ultra-high vacuum system, including ultra-high vacuum chamber 1, the original Mass Spectrometry Module 2, In-Situ Reflection Infrared Spectroscopy Module 3, Energy Spectrum Module 4, Sample Surface Etching and Cleaning Parts 5, Sample Manipulation Table 6, Online Sample Replacement Parts 7, Vacuum Pump Group 8, In-Situ Lighting Components and Gas Injection part.

[0042] The ultra-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com