Method and structure for improving reliability of optical film assembly

An optical film component and optical film technology, applied in optical components, optics, nonlinear optics, etc., can solve the problems of film wrinkle resistance, wear resistance, salt spray resistance, humidity and heat resistance, and difficult maintenance, and achieve strong maintainability. , create simple and efficient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method for improving the reliability of an optical film assembly. First, place the optical film material in a space composed of two layers of optical substrates through an inner ring sealing structure, and vacuumize the space so that the vacuum degree is 10Pa~100Pa , and secondly, perform secondary sealing on the outer side of the inner ring sealing structure, so that the outer ring sealing structure is formed again between the two layers of optical substrates. During specific implementation, the sealing structure of the inner ring is composed of double-sided pressure-sensitive adhesive tape, and the sealing structure of the outer ring is composed of optical adhesive, and may also be composed of other replaceable materials. The key of the present invention is to make the optical film work in a vacuum environment, so as to adapt to the low temperature and negative pressure environment, reduce the internal and external stress difference, and prevent the substrate glass f...

Embodiment 2

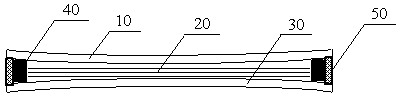

[0029] refer to figure 1 , a high-reliability vacuum optical film assembly is formed by filling the optical film material 20 into the dam structure formed by the upper and lower optical substrates 10, 30 through the inner ring sealing structure 40, and is formed after vacuum treatment and the outer ring sealing structure 50 High-reliability optically reinforced structure. The vacuum degree inside the vacuum optical film assembly is 100 Pa (it can also be set to any value between 10-100 Pa during specific implementation). The optical substrates are the upper anti-reflection glass substrate and the lower strengthened glass substrate respectively, the transmittances are 98% and 92%, the refractive indices are 1.45 and 1.5 respectively, and the coefficients of thermal expansion are both 9×10 -6m / °C, the size of the upper and lower glass substrates is 221mm×168mm; the optical film material is 3 pieces of diffusion film, the size is 217mm×164mm; the sealing materials are silicon-ba...

Embodiment 3

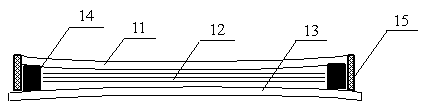

[0031] refer to figure 2 , a high-reliability vacuum optical film assembly is filled with an optical film material 12 in a dam structure composed of upper and lower optical substrates 11, 13 and sealing materials 14, 15. figure 2 It can be seen that the size of the lower optical substrate 13 is larger than that of the upper optical substrate 11 , and a high-reliability optical reinforcement structure is formed after vacuum treatment and secondary sealing. The vacuum degree inside the vacuum optical film assembly is 10 Pa (it can also be set to any value between 10-100 Pa during specific implementation). The optical substrates are the upper reinforced glass substrate 11 and the lower cyclic olefin transparent resin plate 13 respectively, the transmittances are 92% and 93% respectively, the refractive indices are 1.5 and 1.52 respectively, and the thermal expansion coefficients are 9×10 respectively. -6 m / °C and 5×10 -5 m / °C, the dimensions of the upper and lower substrates ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| service temperature | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com