Method for manufacturing photonic crystal fiber integrated end caps

A technology of photonic crystal fiber and fiber, which is applied in the field of fiber optics to achieve the effects of avoiding fiber surface damage and metal impurity sputtering pollution, low manufacturing cost, rapid and uniform collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Take a photonic crystal fiber with an outer diameter of 400 microns, an inner cladding of 200 microns, a core of 40 microns, an outer cladding air hole diameter of 12 microns, and an inner cladding air hole diameter of 2 microns, and first treat it with analytical pure alcohol The surface of the optical fiber, and then place the optical fiber in a standard optical fiber holder, and the distance from the optical fiber clamping position to the end face of the optical fiber is 10cm;

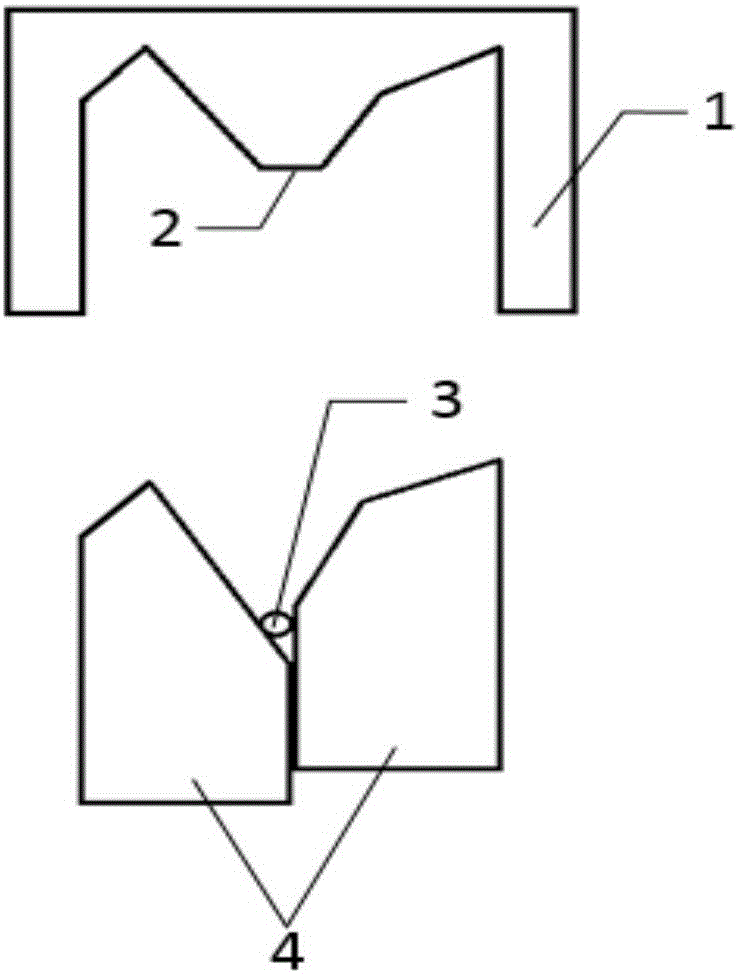

[0030] (2) Place the standard optical fiber clamp in the clamp slot of the optical fiber fusion splicer, place the optical fiber in the two V-shaped grooves of the optical fiber fusion splicer, and set the distance between the two V-shaped grooves to 4cm ; Make the self-made M-shaped V-groove cover (such as figure 1 shown), press down along the concave direction of the V-shaped groove, the flat-bottomed presser foot in the middle of the M-shaped V-shaped groove cover plate (such as figur...

Embodiment 2

[0036] (1) Take a photonic crystal fiber with an outer diameter of 400 microns, an inner cladding of 200 microns, a core of 40 microns, an outer cladding air hole diameter of 12 microns, and an inner cladding air hole diameter of 2 microns, and first treat it with analytical pure alcohol The surface of the optical fiber, and then place the optical fiber in a standard optical fiber holder, and the distance from the optical fiber clamping position to the end face of the optical fiber is 10cm;

[0037] (2) Place the standard optical fiber clamp in the clamp slot of the optical fiber fusion splicer, place the optical fiber in the two V-shaped grooves of the optical fiber fusion splicer, and set the distance between the two V-shaped grooves to 4cm ; Make the self-made M-shaped V-groove cover (such as figure 1 shown), press down along the concave direction of the V-shaped groove, the flat-bottomed presser foot in the middle of the M-shaped V-shaped groove cover plate (such as figur...

Embodiment 3

[0043](1) Take a photonic crystal fiber with an outer diameter of 570 microns, an inner cladding of 430 microns, a fiber core of 110 microns, an outer cladding air hole diameter of 15 microns, and an inner cladding air hole diameter of 3 microns, and first treat it with analytical pure alcohol The surface of the optical fiber, and then place the optical fiber in a standard optical fiber holder, and the distance from the optical fiber clamping position to the end face of the optical fiber is 10cm;

[0044] (2) Place the standard optical fiber clamp in the clamp slot of the optical fiber fusion splicer, place the optical fiber in the two V-shaped grooves of the optical fiber fusion splicer, and set the distance between the two V-shaped grooves to 4cm ; Make the self-made M-shaped V-groove cover (such as figure 1 shown), press down along the concave direction of the V-shaped groove, the flat-bottomed presser foot in the middle of the M-shaped V-shaped groove cover plate (such as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com