Integratable bus power supply circuit

A technology of power supply circuit and bus, applied in the field of integrated bus power supply circuit, can solve the problems of poor power supply characteristics, difficult to determine and grasp the constant current value, unfavorable integration, etc., achieve high-precision measurement or detection characteristics, and realize measurement or detection properties, good consistency and the effect of temperature properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

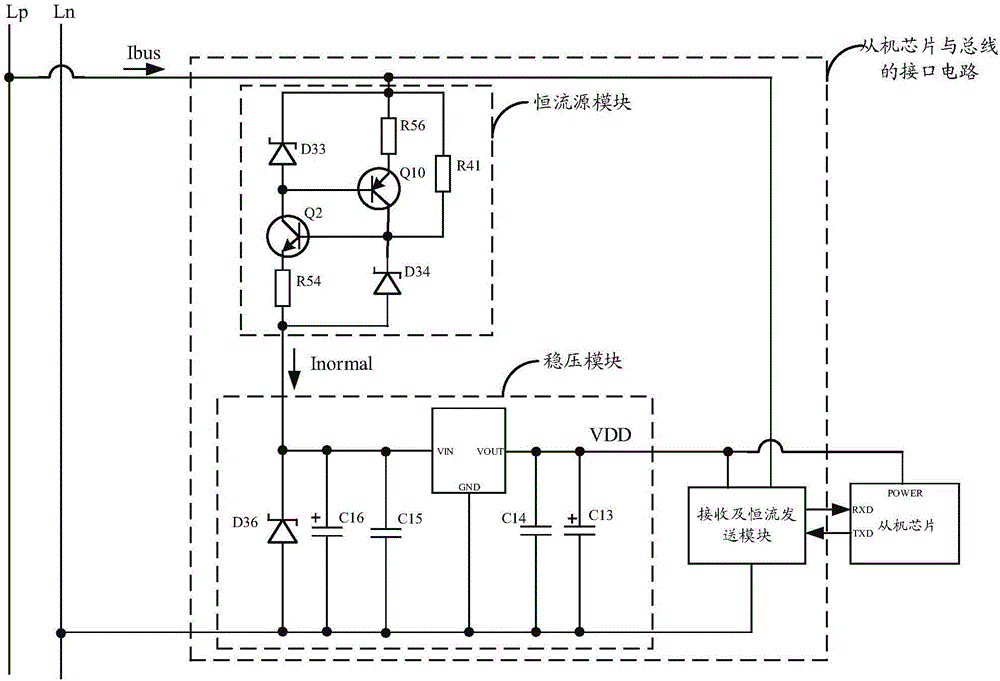

[0027] In order to describe the technical content of the present invention more clearly, further description will be given below in conjunction with specific embodiments.

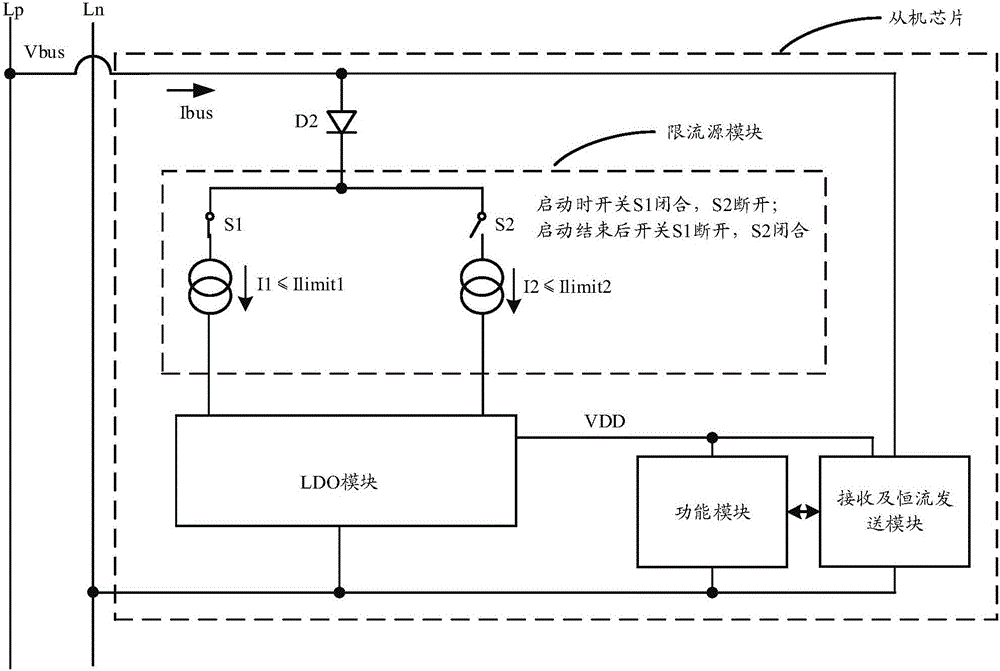

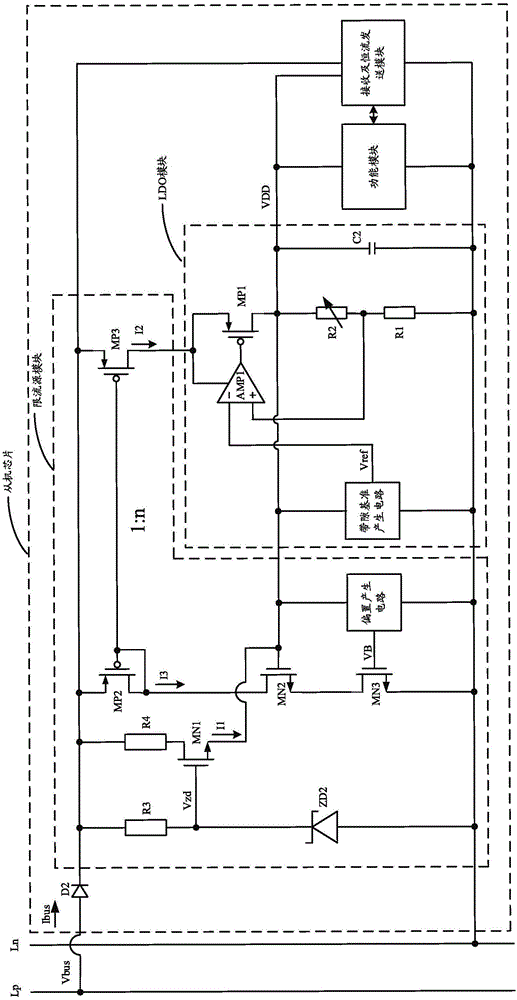

[0028]The bus power supply circuit that can be integrated includes a current limiting source module, an LDO module, a function module, a receiving and constant current sending module and a second diode, and the current limiting source module is connected to the bus negative line Ln, the described The cathode of the second diode, the receiving and constant current sending module are connected to the LDO module, and the LDO module is connected to the functional module and the receiving and constant current sending module respectively , the functional module is connected to the receiving and constant current sending module, and the anode of the second diode is connected to the positive bus line Lp.

[0029] In a preferred embodiment, the current limiting source module includes a second P-type MOS transistor, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com