Preparation method of soft package cylindrical battery and soft package cylindrical battery

A technology of cylindrical batteries and soft packs, applied in small-sized batteries/battery packs, secondary batteries, battery pack components, etc., can solve the problem that the welding stability of the spot bottom welding of the negative pole lugs is not easy to control, and the weight of the packaging shell is large. , packaging batteries are easy to explode, etc., to achieve the effect of high-power discharge performance improvement, small pressure drop, and short moving distance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

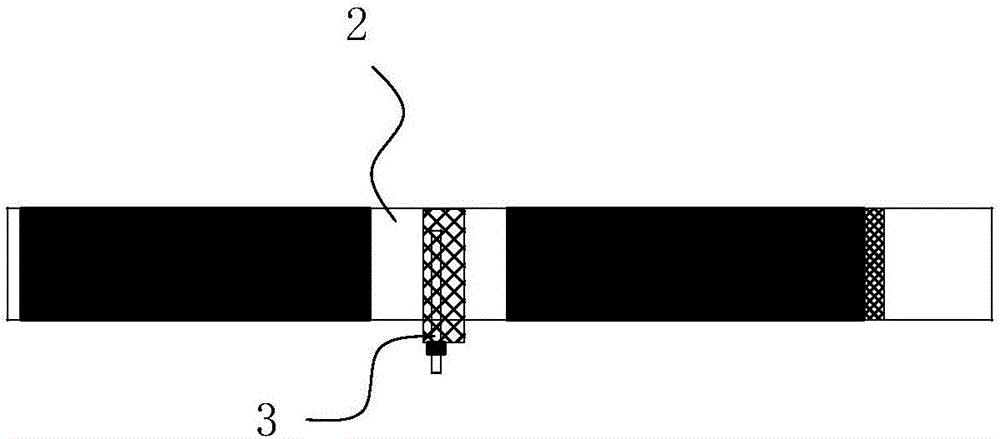

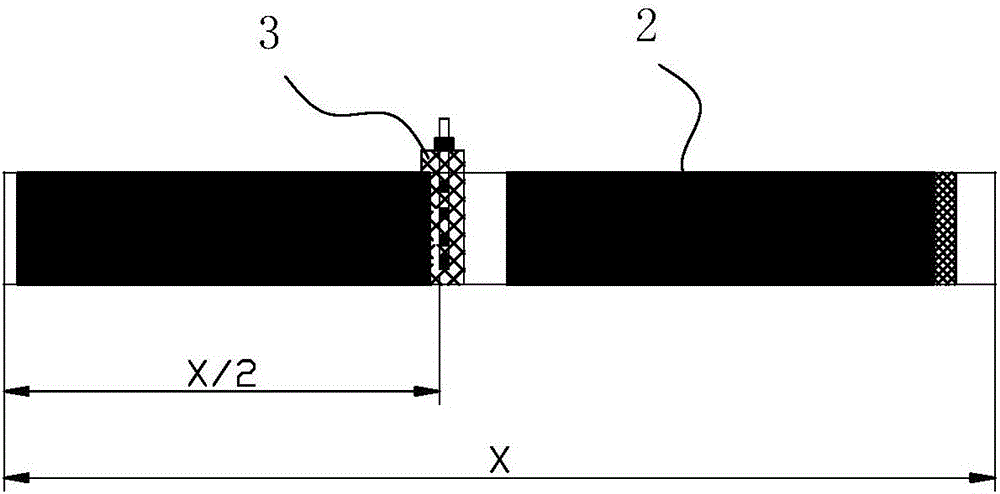

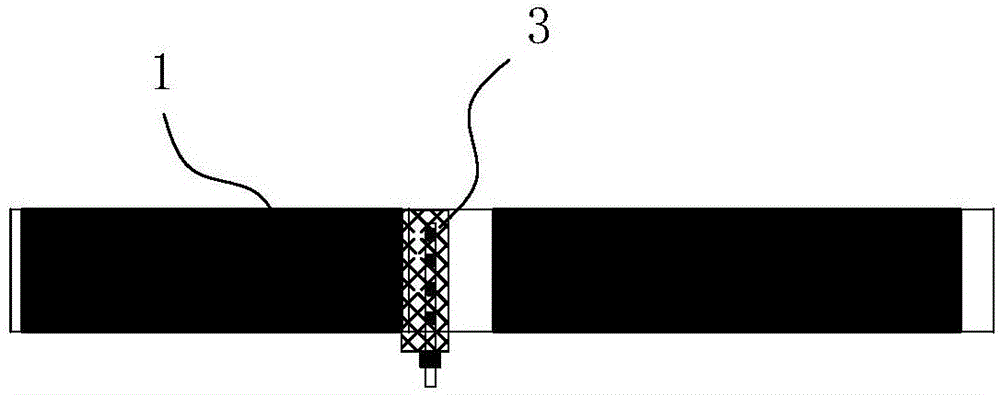

[0037] In the preparation method of the soft-pack cylindrical battery according to the present invention, the preparation of the pole piece includes the preparation of the anode piece, and the preparation of the anode piece includes: the mass ratio is 90-97:0.5-6:1.5-2.5 :1.0~2.0: 100~120 conductive agent graphite, conductive carbon black, sodium carboxymethyl cellulose, styrene-butadiene rubber and water are mixed, stirred at 20~30℃ for 1~4 hours, the stirring rate is 500~1000 revolutions per second to prepare anode slurry. Coat the obtained anode slurry on a copper foil with a thickness of 6-12 μm, dry it at 90°C for 10-30 minutes, then use a tablet machine to press and slice it, and spot-weld the tab on the empty foil in the center of the anode to obtain a long ×width×thickness=915mm×39mm×100μm lithium ion battery anode.

[0038] The preparation of the pole piece includes the preparation of the cathode piece, and the preparation of the battery cathode includes: lithium cob...

Embodiment 1

[0044] 1. Preparation of lithium-ion battery anode:

[0045] The mass ratio LD06-007-01 [conductive agent graphite]: SUPER-P (Timcal company) [conductive carbon black]: CMC [carboxymethyl cellulose]: BM-430B [styrene-butadiene rubber]: H2O=94.5:2 :1.5:2:110 Mix the above components, stir at 700rpm at 25°C for 2.5h, and make lithium ion battery anode slurry.

[0046] Among them, LD06-007-01 is the commercial model of conductive agent graphite (artificial graphite with an average particle diameter of 12.61 μm), and CMC is sodium carboxymethyl cellulose. BM-430B is the product model of styrene-butadiene rubber produced by Japan ZEON Company, with a tensile strength of 70kg / cm2. Then, the obtained anode slurry is coated on an 8 μm thick copper foil, dried at 90°C for 10 minutes, then pressed into pieces with a tablet machine, sliced, and the tab 3 is spot-welded on the empty foil in the center of the anode to obtain length × width × Thickness = 915mm × 39mm × 100μm lithium ion b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com