Self-switching, reversible linear actuator having bifilar control

An actuator, two-wire electric technology, applied in the field of linear electric actuators and reversible actuators, can solve problems such as high cost and temperature limitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

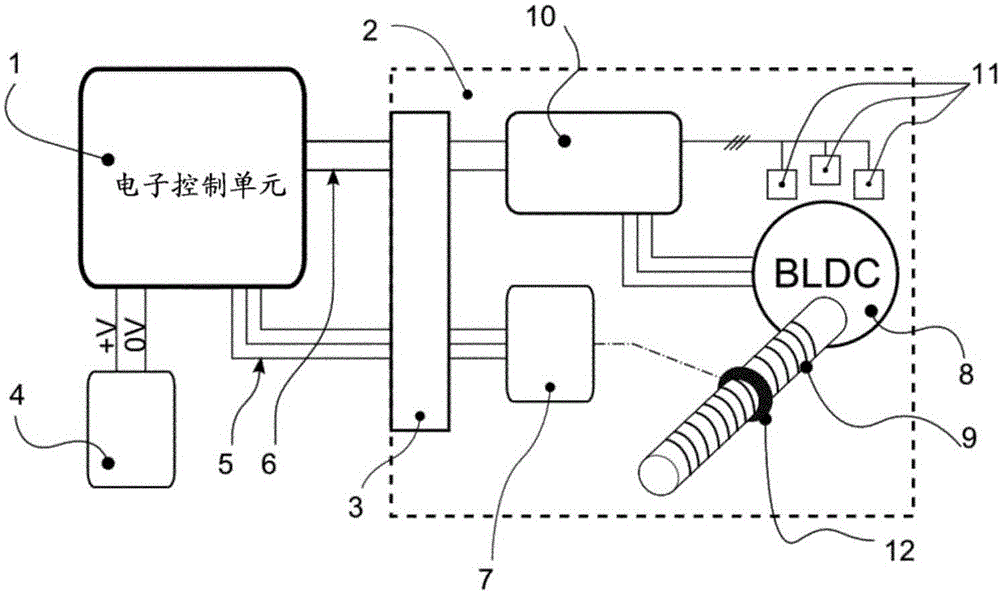

[0051] figure 1 A mechatronic assembly according to the invention is described, comprising a power supply (4) for supplying a control unit (1) which controls an actuator (2) comprising a motor which converts rotation into A brushless DC (direct current) motor constitutes a linearly moving mechanical conversion mechanical assembly (9) associated here represented as a screw nut system. The sensor (7) paired with the mechanical output (12) of the actuator (2), that is, the nut, returns the position information (5) to the control unit (1), and the control unit (1) controls the collected in the connector (3) Signal (6) reacts. The rotor position of the motor (8) is read by means of N probes (11) which automatically switch the N phases of the motor (8) by means of the basic electronic circuit (10).

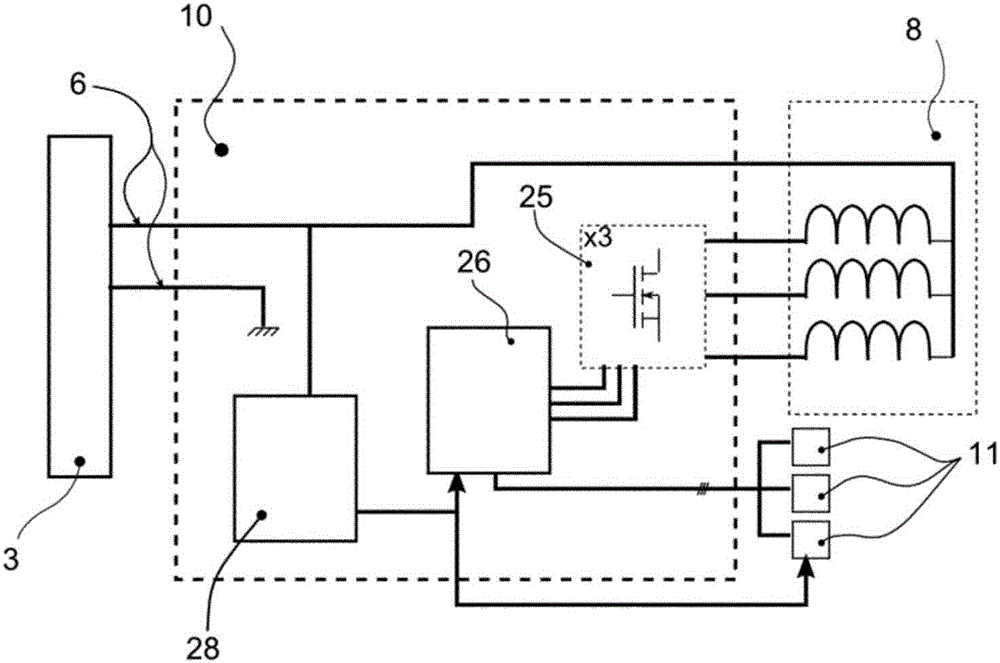

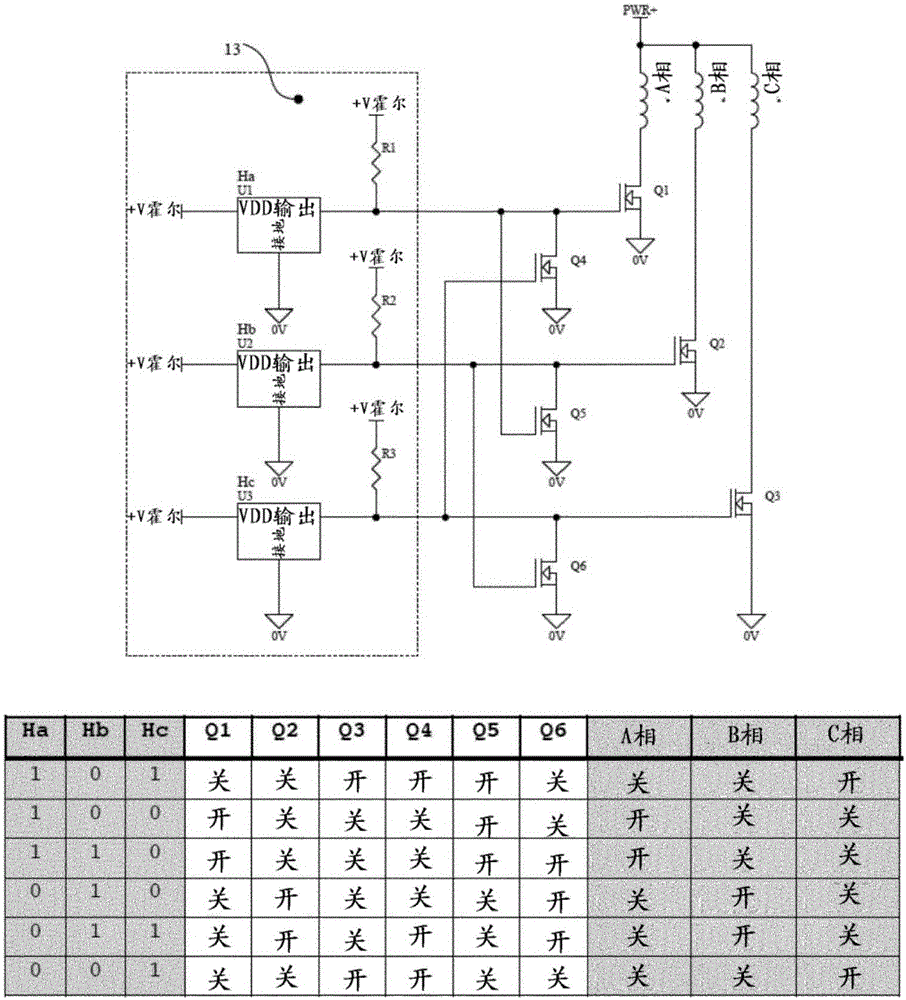

[0052] figure 2 This basic electronic circuit (10) that can be used in the present invention is shown. It includes a set of control transistors (25) which are directly controlled b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com