An automatic packing system for Tetra Brik milk pack gift boxes

An automatic packing and gift box technology, applied in the directions of packaging, transportation and packaging, single objects, etc., can solve the problems of complex packaging process, restricted site, large labor input, etc., to reduce the number of assembly times and complexity, drive mechanism Simple, run-time effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

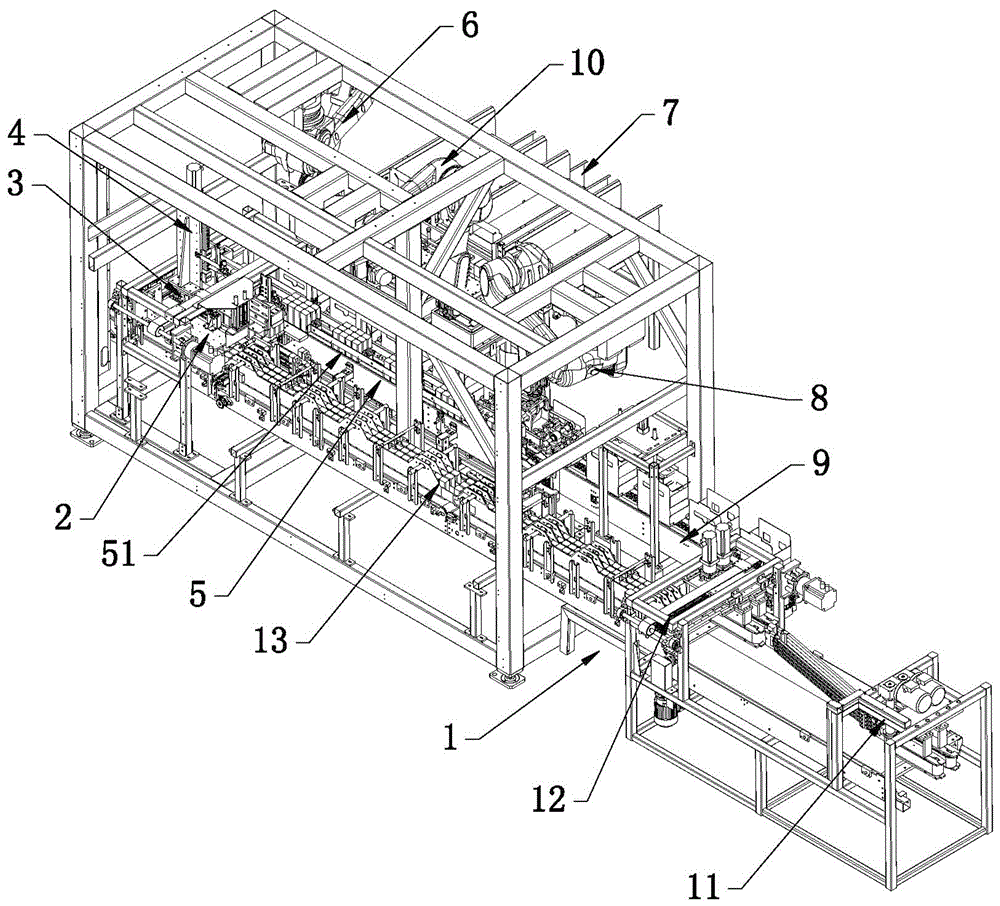

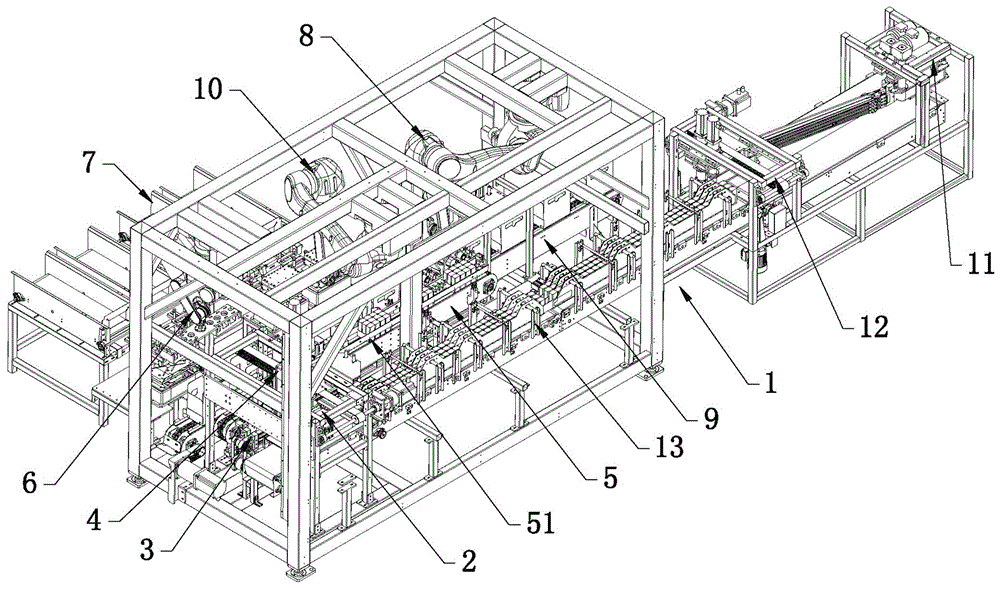

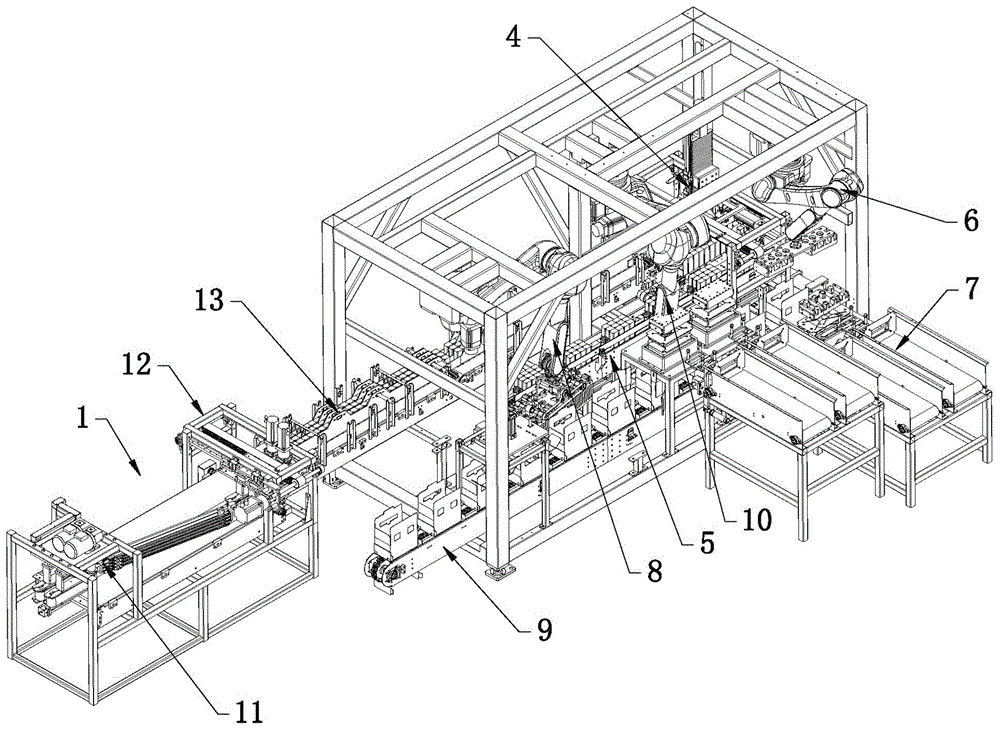

[0058] The Tetra Brik milk bag gift box automatic packing system provided by the present invention is further described by simultaneously integrating and separating two groups of milk bag units, wherein each group of milk bag units is 12 bags / box according to 3*4 specifications And the packing speed is 24000 packs / hour.

[0059] Such as Figure 1-18Shown: when the Tetra Pak milk package gift box automatic packing system of the present invention is in use, the milk package is divided into three lanes through the primary lane dividing mechanism 11 and the secondary lane dividing mechanism 12 and enters the lane dividing conveying track 13, and then Under the action of the counting sensor in the conveying track 13 and the stop cylinder 15, the number of milk bags entering the integration fixture 21 on the milk package integration platform 14 in each wave is 3*8 and counts as 24 packages. Under the action of the rear wall, the blocking piece 28 and the integrated horizontal push ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com