Special grease composition for processed cheese and application thereof

A technology of oil composition and processed cheese, which is applied in the direction of edible oil/fat, edible oil/fat phase, application, etc., can solve the problems that processed cheese cannot be applied, and achieve good plasticity, good production and cutting, and good adaptability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

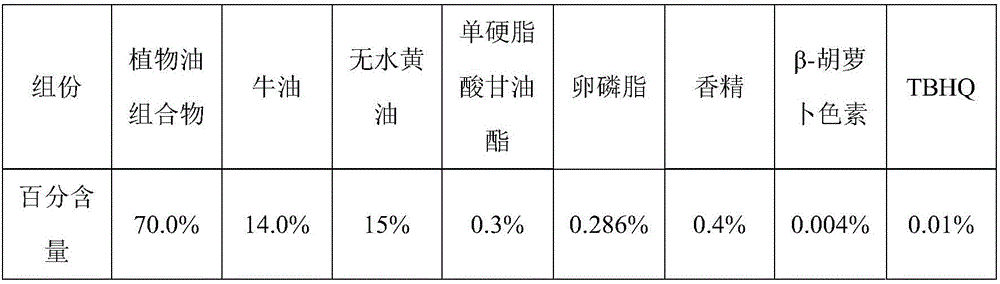

[0066] The special oil and fat composition for processed cheese, the content of each component is shown in Table 1:

[0067] Table 1 Component content of special oil and fat composition for processed cheese

[0068]

[0069] The vegetable oil composition of this embodiment: soybean oil, palm oil, palm oil fractionation products, and palm kernel oil fractionation products are selected, and the proportions of each component are: soybean oil 2%, palm oil 50%, and palm oil fractionation products 40% , palm kernel oil fractionation product 8%; among them, the palm oil fractionation product is a first-level fractionation product, which adopts a conventional dry extraction method, and obtains an iodine value of 33-35gI / 100g and a melting point of 50-55g after the first fractionation. °C palm stearin. The palm kernel oil fractionation product is a one-stage fractionation of palm soft fat, with an iodine value of 20-30gI / 100g and a melting point of 18-28°C.

[0070] In the prepara...

Embodiment 2

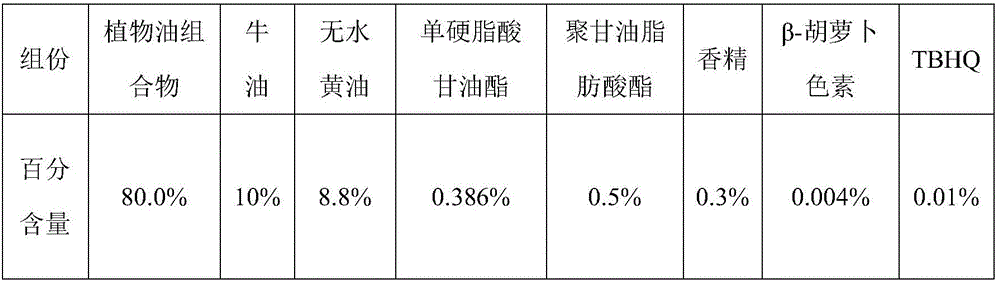

[0072] Special oil and fat composition for processed cheese, the content of each component is shown in Table 2:

[0073] Table 2 Component content of special oil and fat composition for processed cheese

[0074]

[0075] The vegetable oil composition of this embodiment: select palm oil, palm oil fractionated products, and palm kernel oil, and the proportion of each component: palm oil 72%, palm oil fractionated product 20%, palm kernel oil 8%, wherein, palm oil The oil fractionation product is a multi-stage fractionation product. The first fractionation obtains palm soft fat with an iodine value of 54-57gI / 100g and a melting point of 22-26°C; and then the palm soft fat is extracted several times to obtain the multi-stage palm soft fat. Fractional products. Specifically, it refers to the iodine value of the palm oil multi-fraction extraction product of 42-48gI / 100g, and the sliding melting point of 26-30℃.

[0076] In the preparation process of this embodiment, the oil and...

Embodiment 3

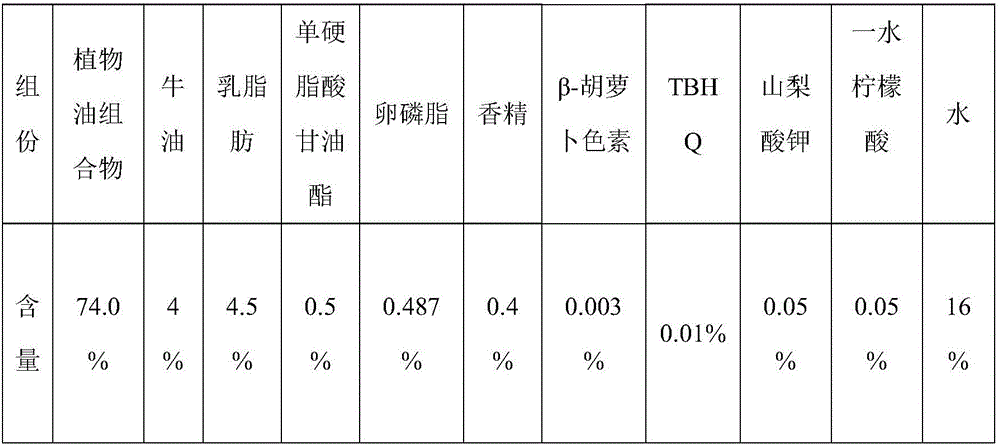

[0078] Special oil and fat composition for processed cheese, the content of each component is shown in Table 3:

[0079] Table 3 Component content of special oil and fat composition for processed cheese

[0080]

[0081] The vegetable oil composition of this embodiment: select palm oil, palm oil fractionated products, and palm kernel oil fractionated products, and the proportions of each component: palm oil 58%, palm oil fractionated products 35%, palm kernel oil fractionated products 7% , wherein the palm oil fractionation product is a first-stage fractionation product, which adopts conventional dry extraction, and obtains palm stearin with an iodine value of 33-35gI / 100g and a melting point of 50-55°C after the first fractionation; palm kernel The oil fractionation product is a first-stage fractionation product. After one fractionation, palm kernel soft fat with an iodine value of 23-28gI / 100g and a sliding melting point of 18-28°C is obtained.

[0082] In the preparatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com