Micro-fluidic chip for cell freezing, mixing system and control method of mixing system

A microfluidic chip and mixing system technology, applied in fluid controllers, mixers, laboratory containers, etc., can solve problems such as lack of cell fine manipulation, improve survival rate, meet industry needs, and stabilize survival rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

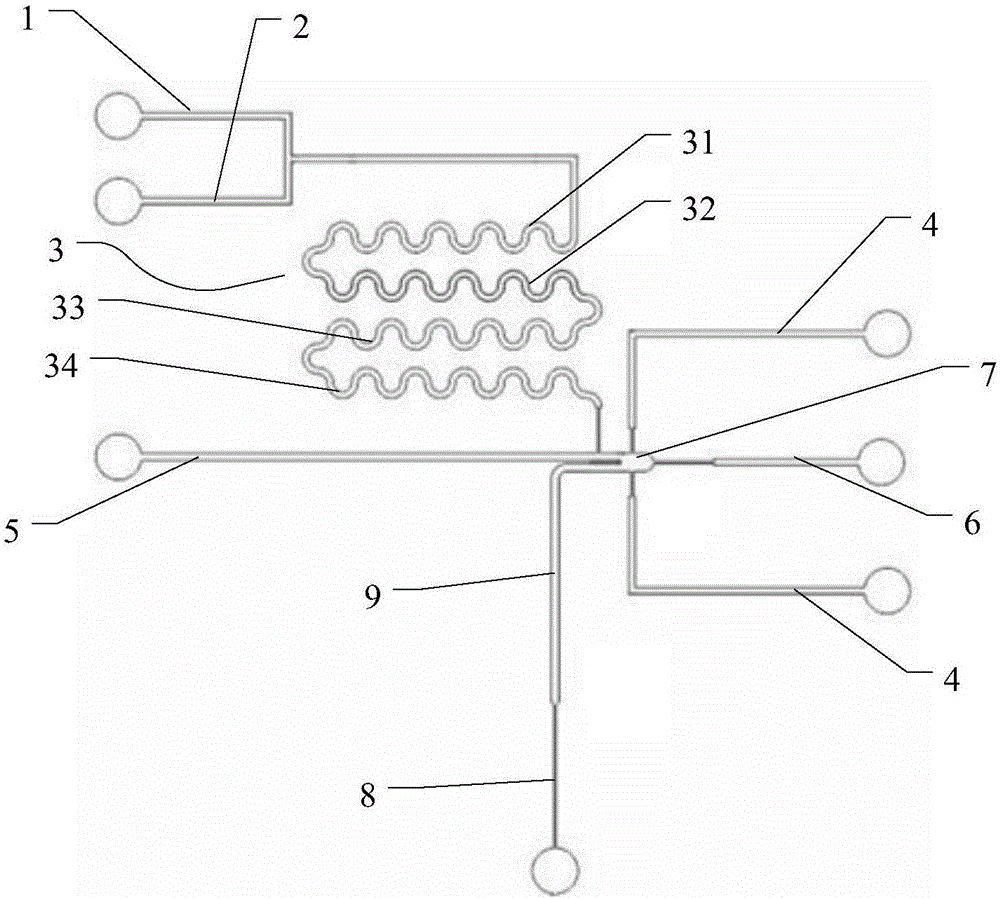

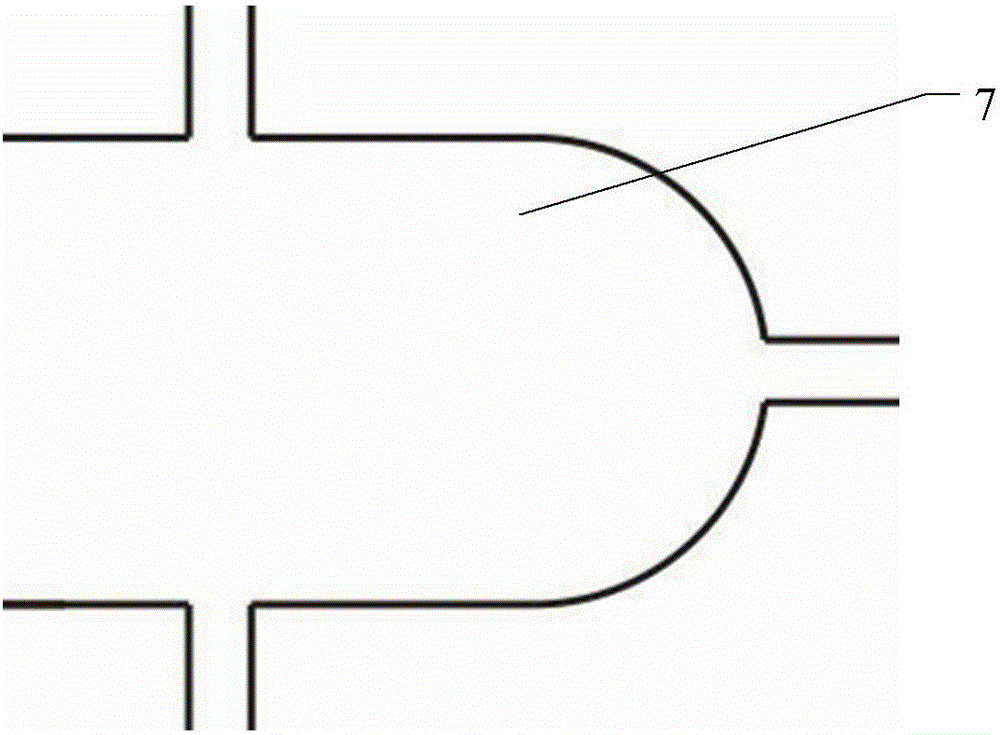

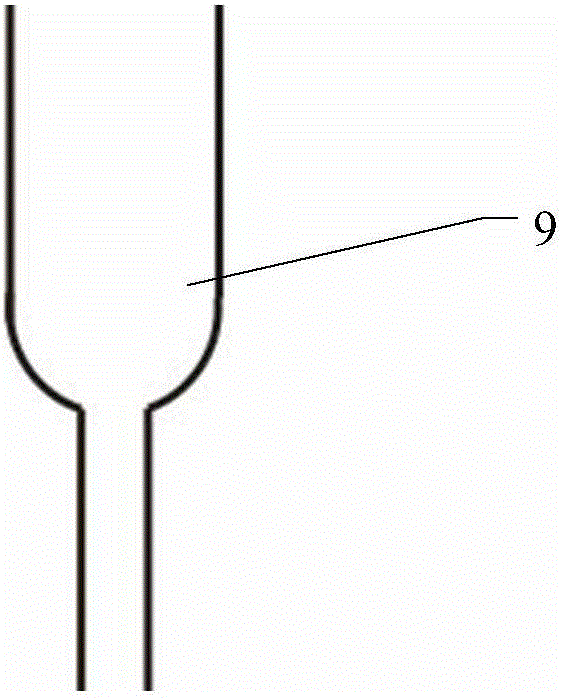

[0047] like Figure 1~Figure 3 As shown, a microfluidic chip for cell freezing includes a microfluidic chip body, and the microfluidic chip body includes a first reagent inflow channel 1, a second reagent inflow channel 2, and a reagent mixing flow channel. Channel 3, third reagent inflow channel 4, cell inflow channel 5, recoil channel 6, reaction chamber 7, cell mixture outflow channel 8, the first reagent inflow channel 1, the second reagent inflow channel The channel 2 communicates with the inlet of the reagent mixing channel 3 respectively, and the outlet of the reagent mixing channel 3 communicates with the reaction chamber 7. The inner wall of the reaction chamber 7 is arc-shaped, and the reaction chamber 7 and the cell mixture flow out The inner diameter of the flow channel 8 is larger than the outer diameter of the cells. The cell mixture outflow channel 8 is connected with a cell mixture storage chamber 9 , and the inner diameter of the cell mixture storage chamber ...

Embodiment 2

[0051] On the basis of Example 1, such as Figure 4 As shown, the microfluidic chip for cell freezing includes a liquid storage pool 10, the liquid storage pool 10 is connected to the cell inflow channel 5 through a connecting pipe 11, and the inner diameter of the connecting pipe 11 is greater than 150 μm; The height of the reservoir 10 is higher than that of the microfluidic chip.

Embodiment 3

[0053] On the basis of Example 1, such as Figure 5 As shown, the reagent mixing channel 3 is provided with obstacles 12 for thorough mixing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com